Silicon carbide semiconductor device and method for manufacturing the same

a technology of silicon carbide and semiconductors, applied in the direction of semiconductors, semiconductor devices, electrical apparatus, etc., can solve the problems of silicon semiconductors not being suitable for use in such severe environments, power devices are sometimes required to operate in severe environments, and silicon power devices are now approaching the theoretical limit, etc., to achieve low resistance ohmic contact, improve switching characteristics, and reduce the effect of resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

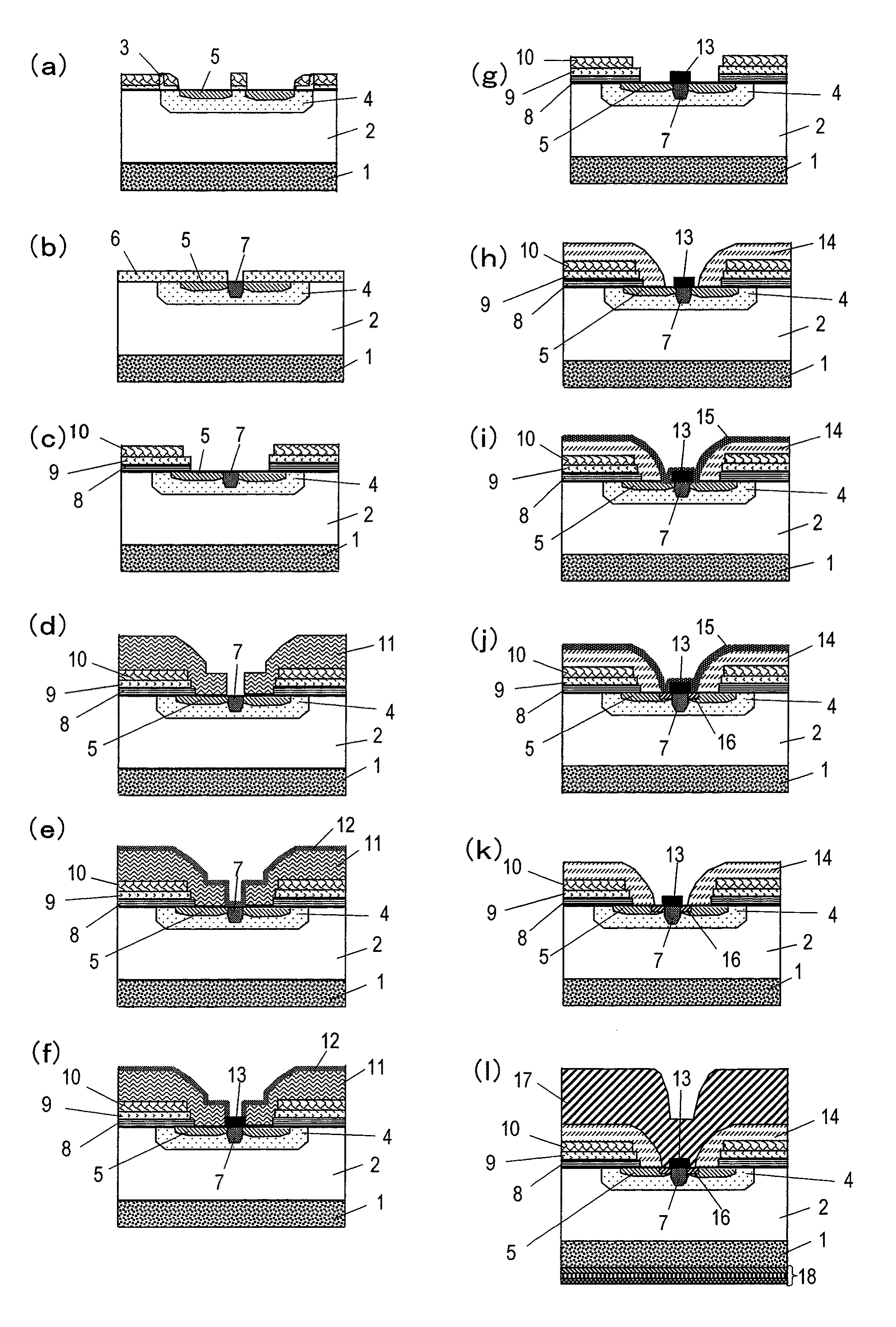

embodiment 1

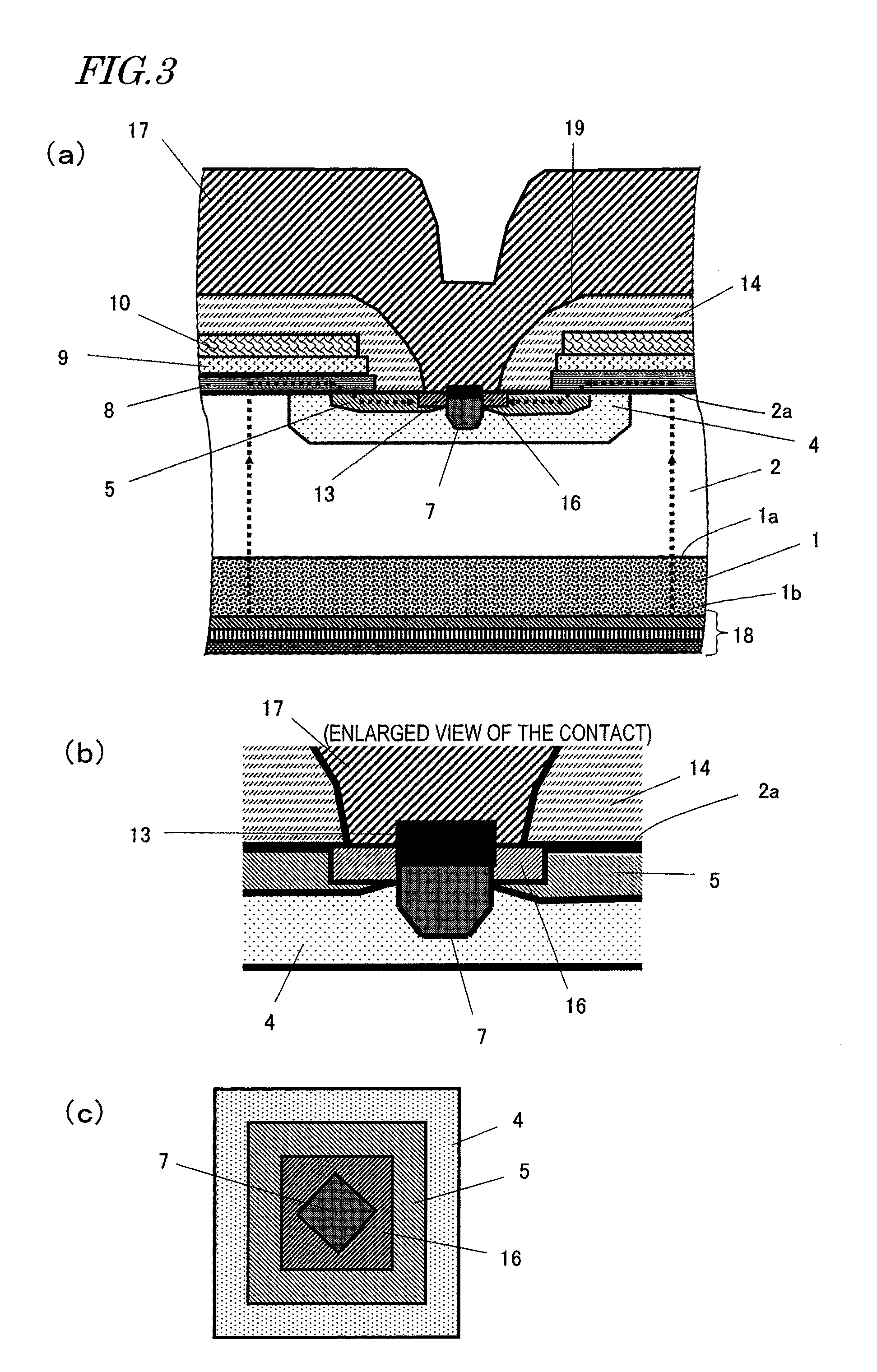

[0081]FIG. 3(a) is a schematic cross-sectional view showing a semiconductor device in Embodiment 1 According to the present invention. The semiconductor device shown in FIG. 3(a) includes a silicon carbide semiconductor layer 2.

[0082]The silicon carbide semiconductor layer 2 is formed of a silicon carbide semiconductor. The silicon carbide semiconductor layer 2 may be a bulk forming a semiconductor substrate or an epitaxial layer formed on a semiconductor substrate. In this embodiment, the silicon carbide semiconductor layer 2 is formed on a silicon carbide semiconductor substrate 1 by epitaxial growth. The silicon carbide semiconductor substrate 1 is an off substrate having an off angle of, for example, 8 degrees from the (0001) surface of 4H—SiC. The silicon carbide semiconductor substrate 1 is doped with an n-type impurity such as nitrogen, phosphorus, arsenic or the like at a concentration of, for example, 1×1018 cm−3 or higher, and has a low resistance. The silicon carbide semi...

embodiment 2

[0134]FIG. 5(a) is a schematic cross-sectional view showing a semiconductor device in Embodiment 2 according to the present invention. FIG. 5(b) is a cross-sectional view showing, in enlargement, a structure of an n-type ohmic electrode 16, a p-type ohmic electrode 13 and the vicinity thereof.

[0135]The semiconductor device in this embodiment is different from that in Embodiment 1 in the following points: (1) a nitrogenized titanium layer 15′ is provided on a side surface of the contact hole of the second interlayer insulating layer 14; (2) the n-type ohmic electrode 16 includes an n-type reaction layer 16a containing an alloy of titanium, silicon and carbon and a titanium nitride layer 16b; and (3) the p-type ohmic electrode 13 includes a p-type reaction layer 13a containing an alloy of nickel, aluminum, titanium, silicon and carbon and a titanium nitride layer 13b.

[0136]The nitrogenized titanium layer 15′, the titanium nitride layer 16b and the titanium nitride layer 13b are deriv...

experiment examples

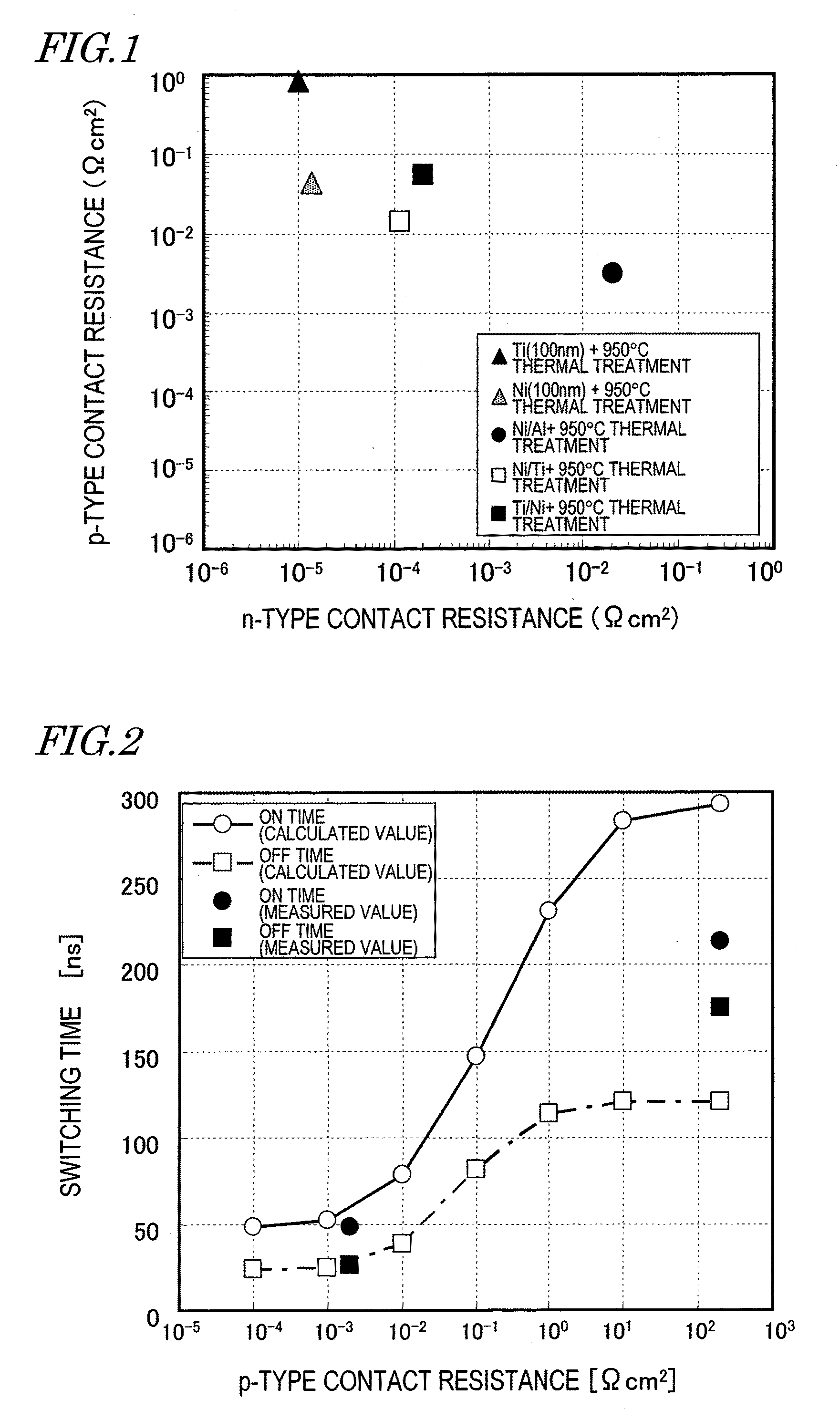

[0155]In order to confirm the effects of the present invention, the electric characteristics of the p-type ohmic electrode 13 were measured and the composition thereof was analyzed. The results are shown below.

1. Electric Characteristics of the P-Type Ohmic Electrode 13

[0156]FIG. 8 shows the current vs. voltage characteristic of a p-type contact formed as follows as in Embodiment 1. On a p-type silicon carbide semiconductor substrate having an impurity concentration of 5×1019 cm−3, a nickel / aluminum stacking layer, a nickel layer, and a titanium layer were each vapor-deposited and thermally treated at 950° C. for 2 minutes. As shown in FIG. 8, the ohmic characteristic provided by a nickel / aluminum layer shows a significant improvement in the current vs. voltage characteristic over the case where a silicide layer of a single nickel layer or a silicide layer of a single titanium layer is formed, and an ohmic characteristic is realized even at a low concentration of nickel / aluminum. Fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com