Instrument docking station for an automated testing system

a technology of automated testing and instrument docking station, which is applied in the field of life sciences industry, can solve the problems of affecting the future integration of additional laboratory devices and the repair and/or upgrading of laboratory devices, affecting the quality of instrument docking station, etc., and achieves the effects of low cost of production, high repeatability, and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

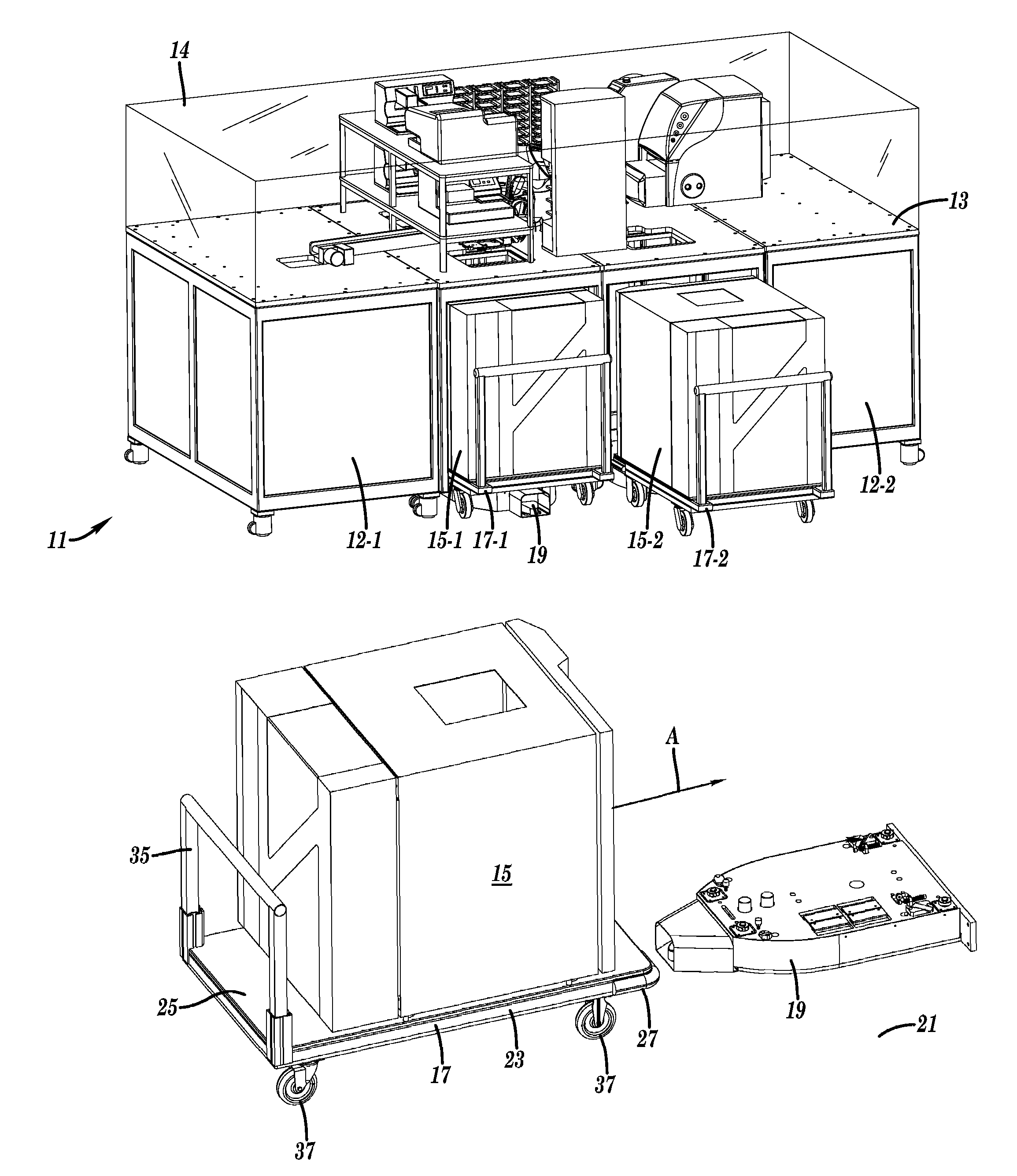

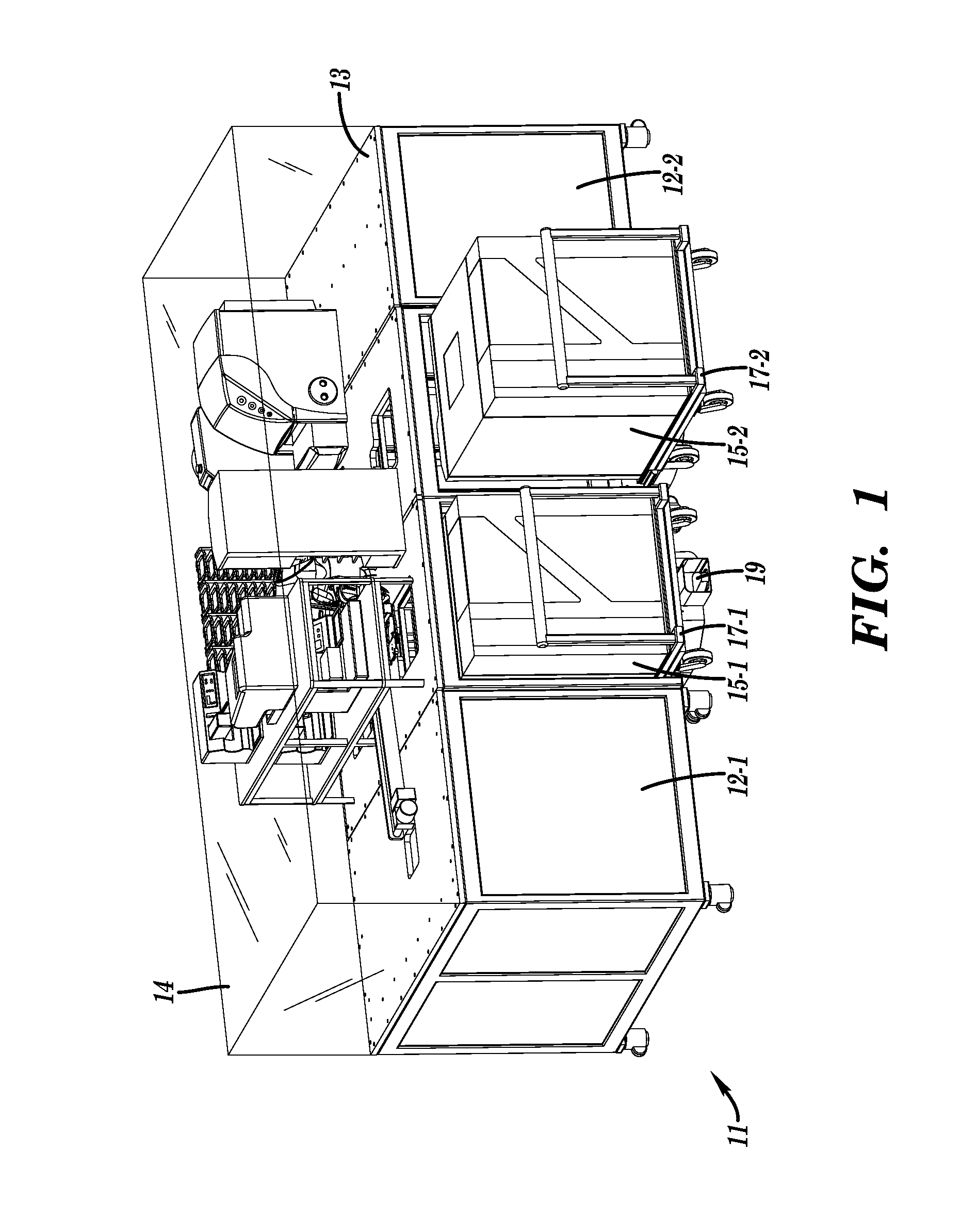

[0035]Referring now to FIG. 1, there is shown an automated testing system that is constructed according to the teachings of the present invention, said automated testing system being identified generally by reference numeral 11. As can be appreciated, system 11 is designed principally for use in conducting laboratory research in the life sciences industry and may be used, more specifically, to perform high throughput screening (HTS) in the life sciences industry.

Automated Testing System (11)

[0036]System 11 comprises a pair of fixedly mounted end units 12-1 and 12-2 which together support a flat table surface 13 on which certain laboratory devices are fixedly mounted. Preferably, a transparent testing chamber 14 is mounted on table surface 13 over said devices in order to provide an enclosed testing environment that may be regulated by the operator to optimize results.

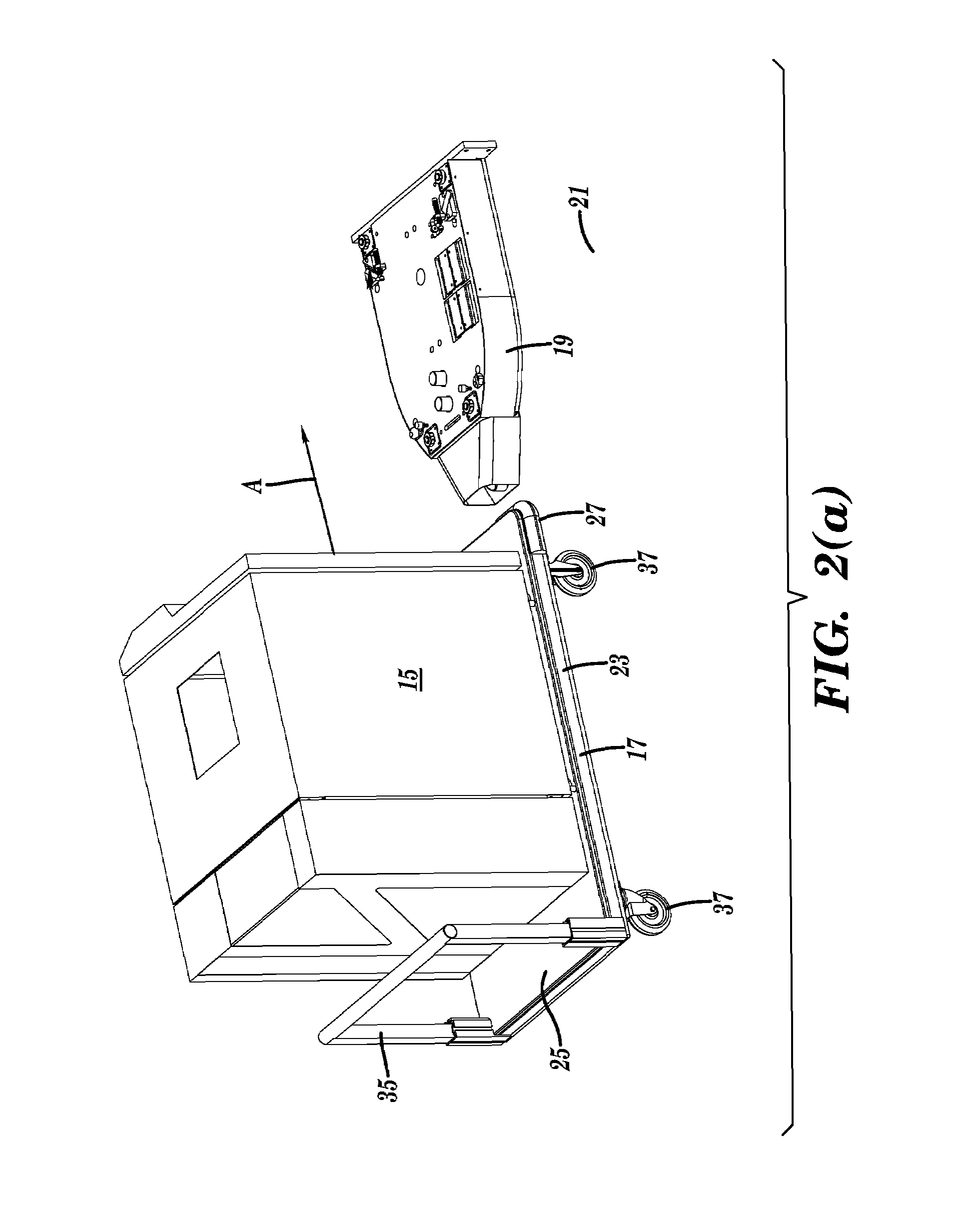

[0037]System 11 additionally includes a pair of automated laboratory devices 15-1 and 15-2 that are configured to be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of displacement | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| electrical | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com