System and method for monitoring a vertical shaft impact crusher

a technology of vertical shaft and monitoring system, which is applied in the direction of testing/monitoring control system, process and machine control, instruments, etc., can solve the problems of unfavorable lubrication of the crusher, and increased winding temperatur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

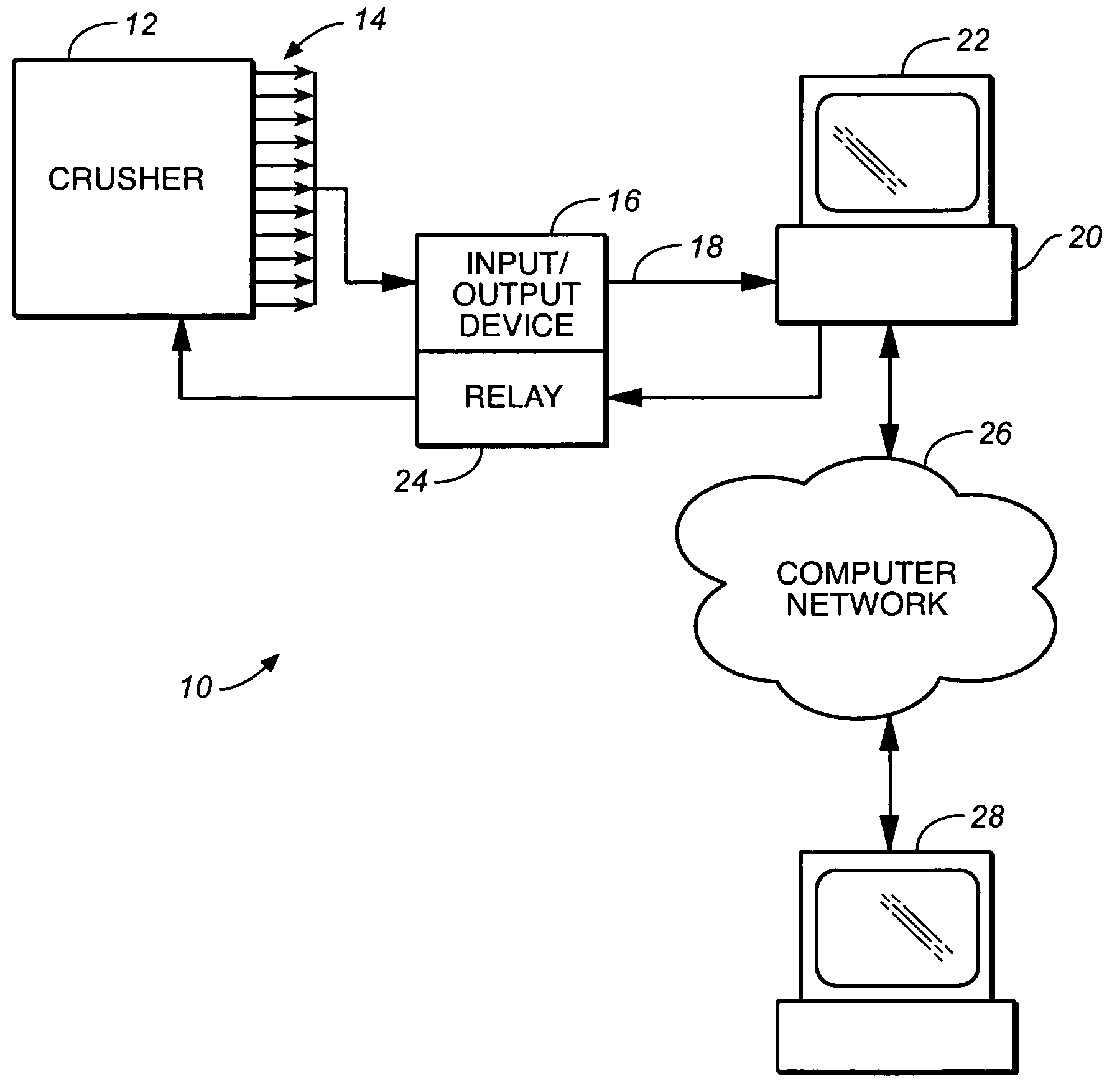

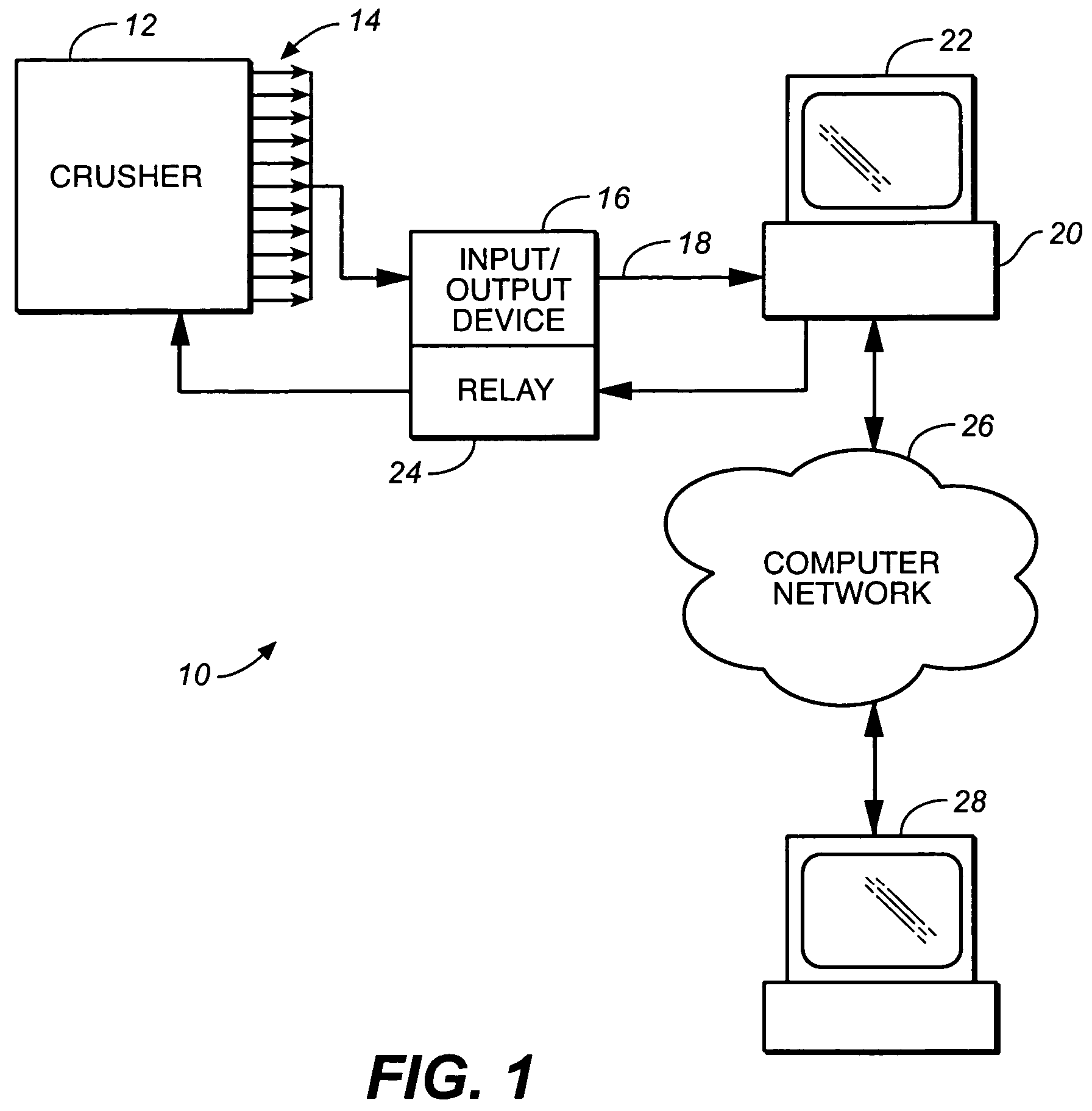

[0017]FIG. 1 is a graphic representation of a monitoring system for a VSI crusher according to the invention.

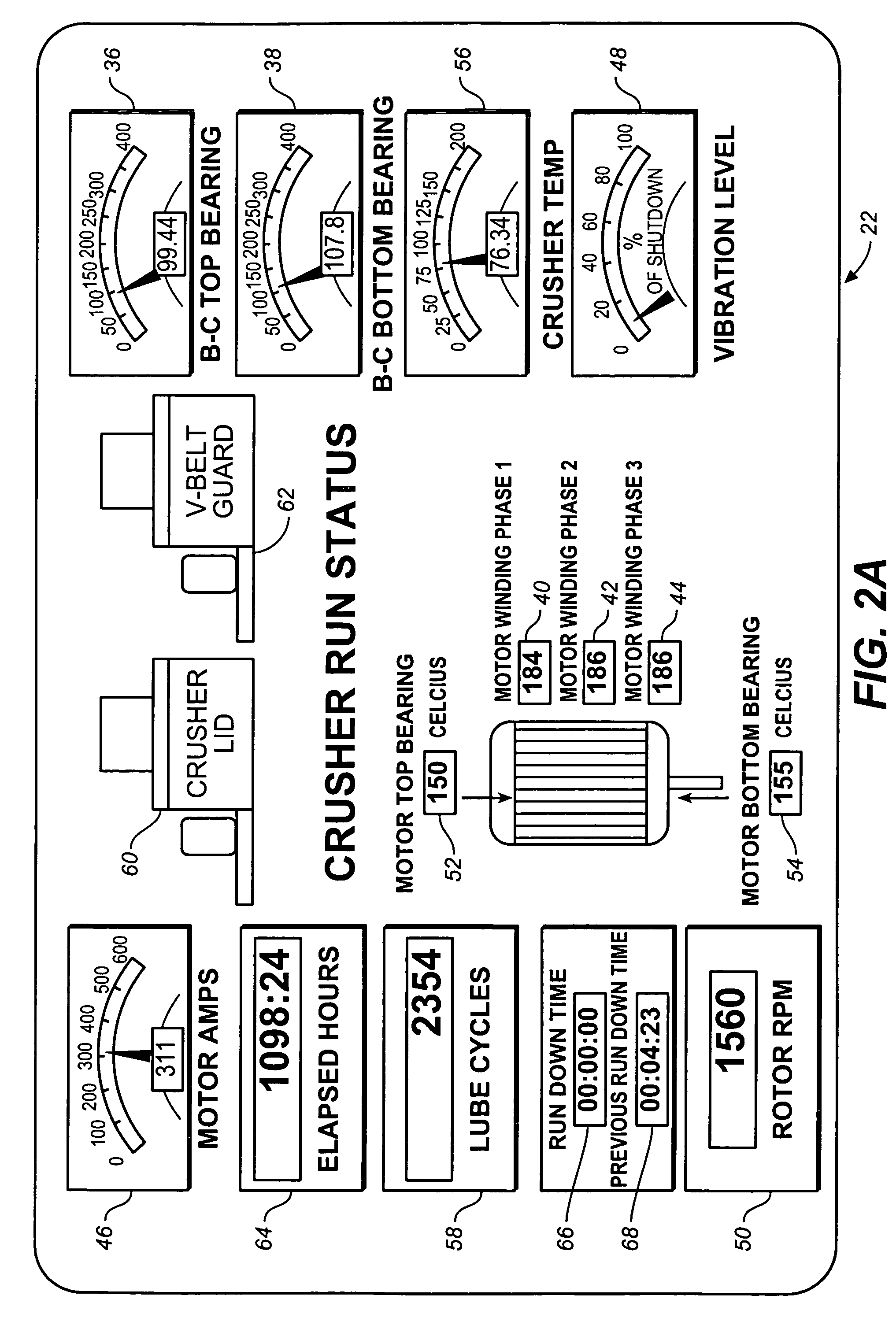

[0018]FIG. 2 is a graphic representation of the display of the monitoring system of FIG. 1.

[0019]FIGS. 3A, 3B and 3C are exemplary representations of historical data viewers depicting historical information regarding the status of motor amps, bearing temperature, and crusher vibration, respectively.

[0020]FIG. 4 is a schematic diagram showing the process for interpreting the signals from the system sensors and for the alarm and shutdown processes according to the invention.

[0021]FIG. 5 is a schematic diagram showing the process for monitoring the run down time of the rotor of a VSI crusher according to the invention.

[0022]FIG. 6 is a schematic diagram showing the process for monitoring the elapsed hours of operation of the motor of a VSI crusher according to the invention.

DETAILED DESCRIPTION OF THE ILLUSTRATED EMBODIMENT

[0023]With reference initially to FIG. 1 of the accompan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com