MEMS capacitive cantilever strain sensor, devices, and formation methods

a capacitive cantilever and strain sensor technology, applied in the field of sensing, can solve problems such as capacitance change, and achieve the effects of high compactness, and low power strain sensor devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

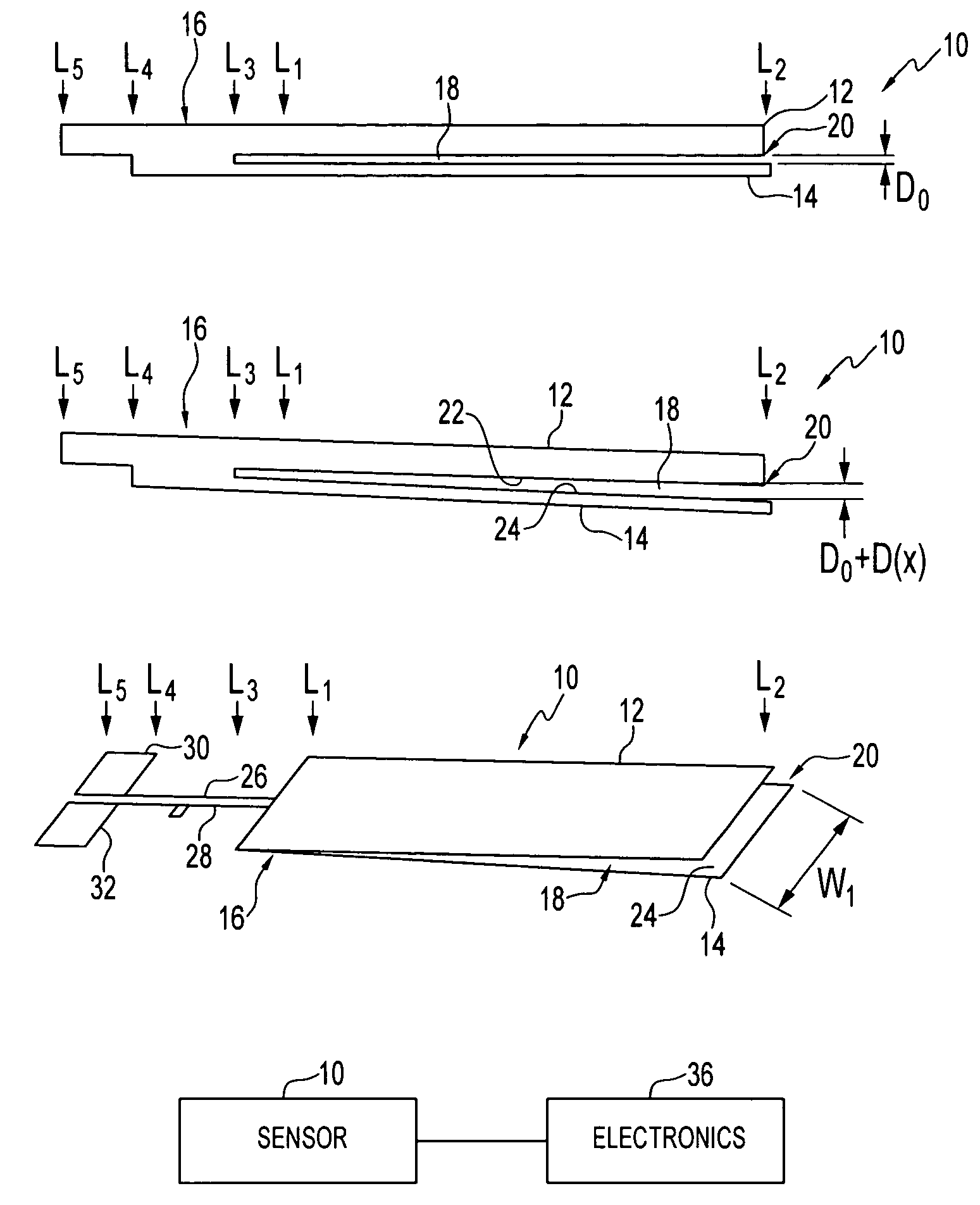

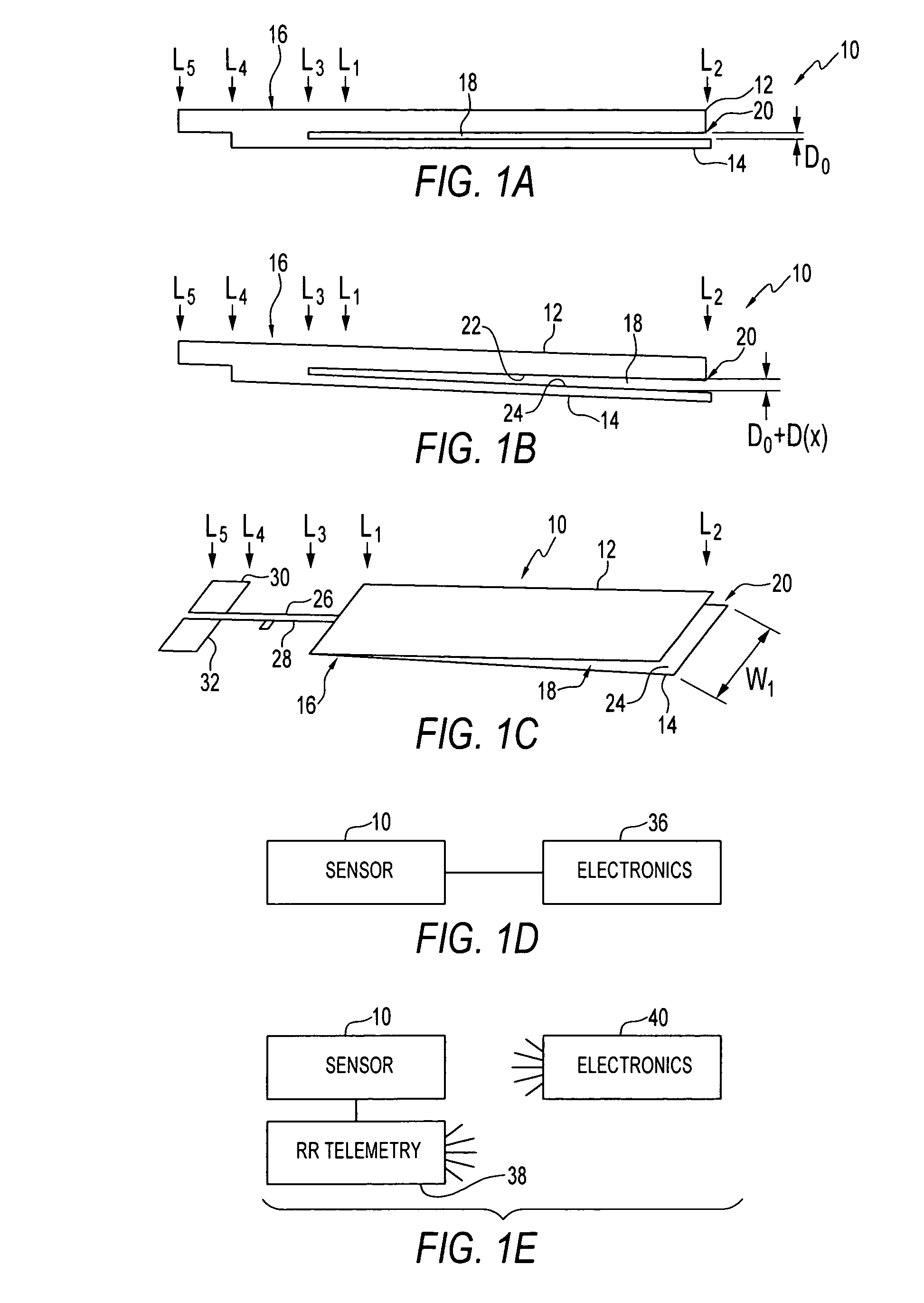

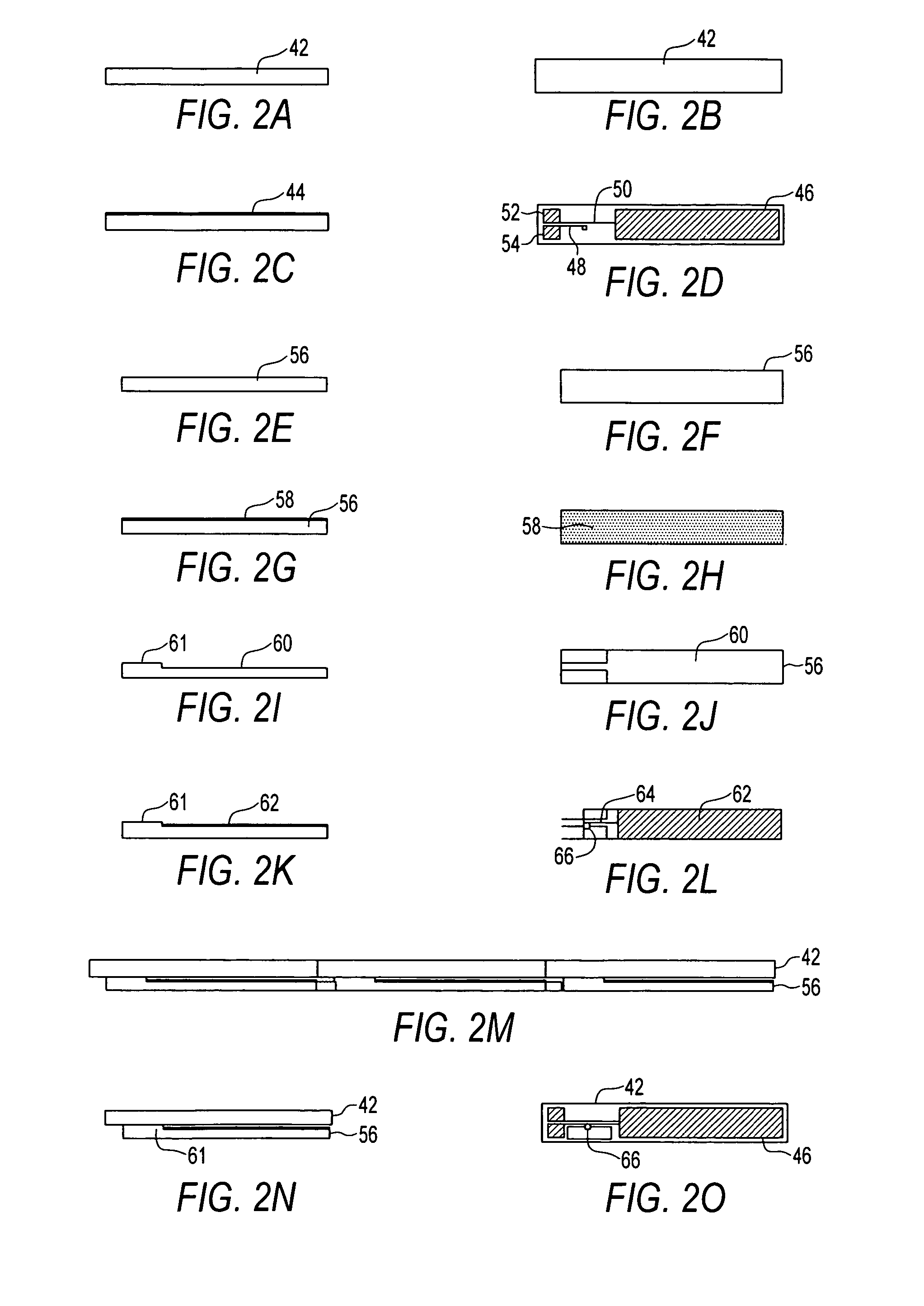

[0012]The invention provides a MEMS capacitive cantilever strain sensor. A sensor of the invention may monitor the mechanical strain of a member to which the sensor is attached, or a member to be monitored can comprise the substrate of a sensor of the invention. The value of capacitance between the opposing cantilever micro-scale plates of the invention varies under load conditions. A variable capacitor is thus produced whose capacitance depends on the load supplied. Devices of the invention may be formed from a variety of materials, including semi-conductor materials, glass, and plastics. Any dielectric material or a material that can be treated to have dielectric qualities and that can be fabricated by MEMS processing techniques can be used as the basis for the cantilever structure in a MEMS strain sensor of the invention, so long as a conductive material can be formed on the opposing surfaces of the dielectric opposing cantilever micro-scale plates.

[0013]Exemplary MEMS cantilever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com