Filter system employing microwave regeneration

a filter system and microwave technology, applied in the field of filter systems, can solve the problems of excessive pressure drop across the filter, undesirable or even disastrous, etc., and achieve the effect of avoiding undesired pressure drop (back pressure) and large gas flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

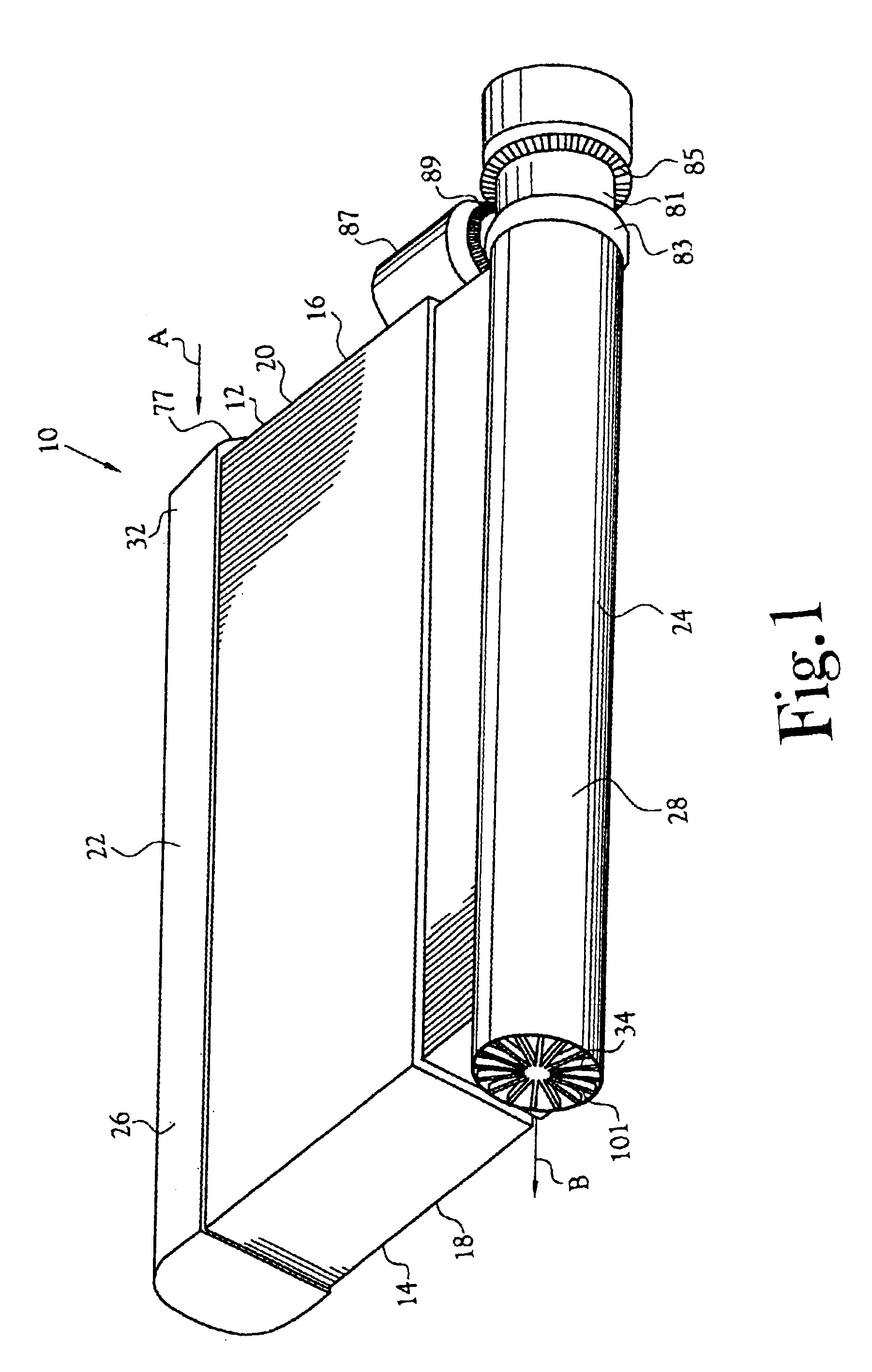

Referring specifically to FIG. 1, the depicted embodiment of a filter system 10 of the present invention includes a housing 12, which in the depicted embodiment is of a generally rectangular cross-section having its opposite short sides 14,16 sealed by respective end plates 18,20. Each of the opposite longer sides 22,24 of the housing preferably is rounded and partially defines an inlet plenum 26 and an outlet plenum 28, respectively, for the flow of a gas stream (see arrows) through the filter system.

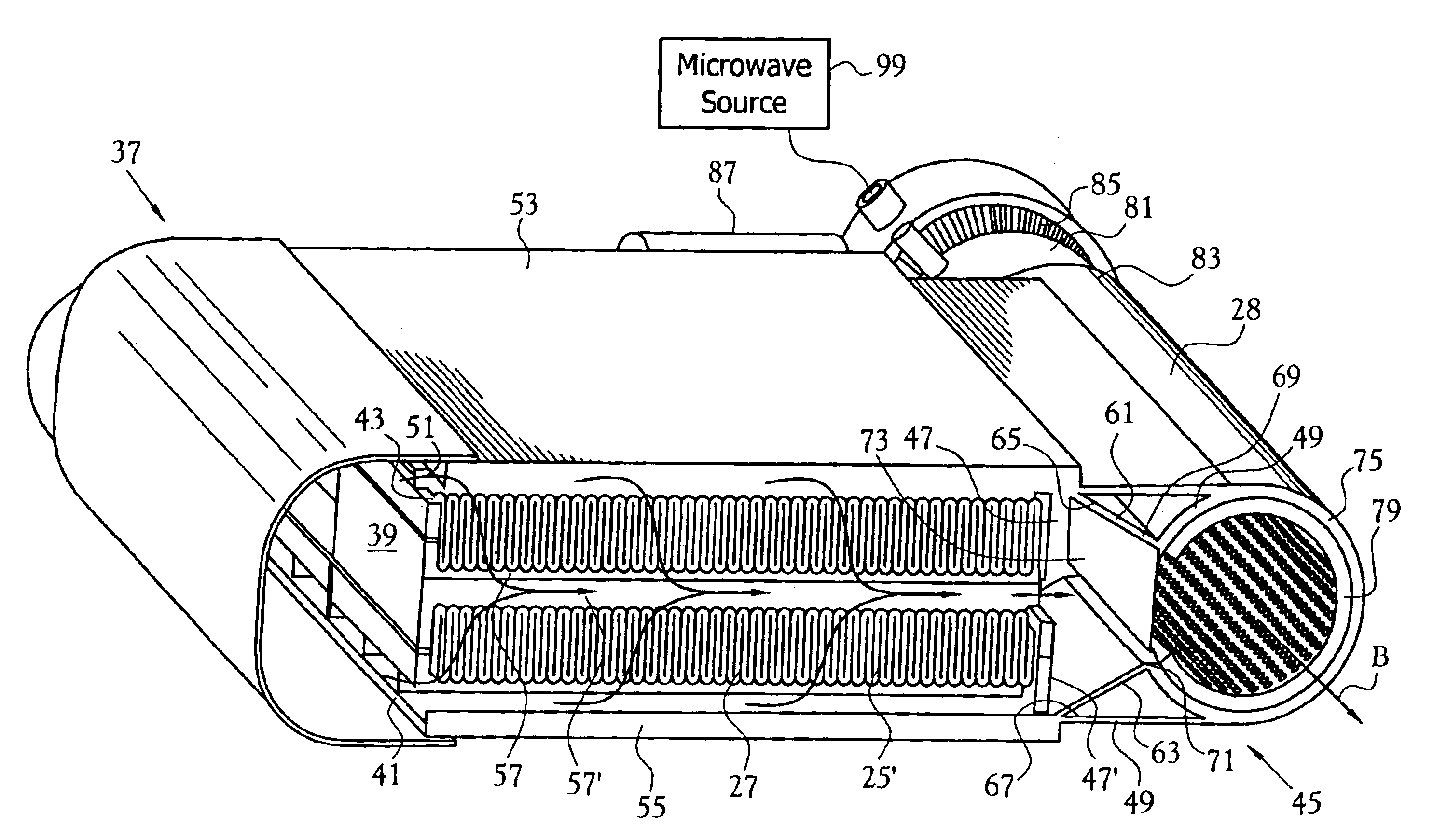

Internally of the housing there is provided at least one, and preferably a plurality of filter modules 25 (see FIG. 5), each of which, in the depicted embodiment includes a pleated ceramic filter paper 27 captured between first and second comb elements 29,31 (typical), respectively, (see FIGS. 6 and 7). As seen in FIGS. 2 and 5, the top margins (ribs) 33 of each comb projects above the planar level of the pleated paper, thereby defining multiple gas flow channels 35 (typical, see arrow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| microwave energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com