Method of manufacturing a solid-state imaging device

a solid-state imaging and manufacturing method technology, applied in semiconductor devices, radio-controlled devices, electrical apparatuses, etc., can solve the problems of reduced transfer efficiency and transfer charge quantity, reduced resolution of conventional imaging devices, and reduced sensitivity when transparent films are thick, so as to achieve superior sensitivity or resolution, reduce the effect of transfer efficiency or transfer charge quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[First Embodiment]

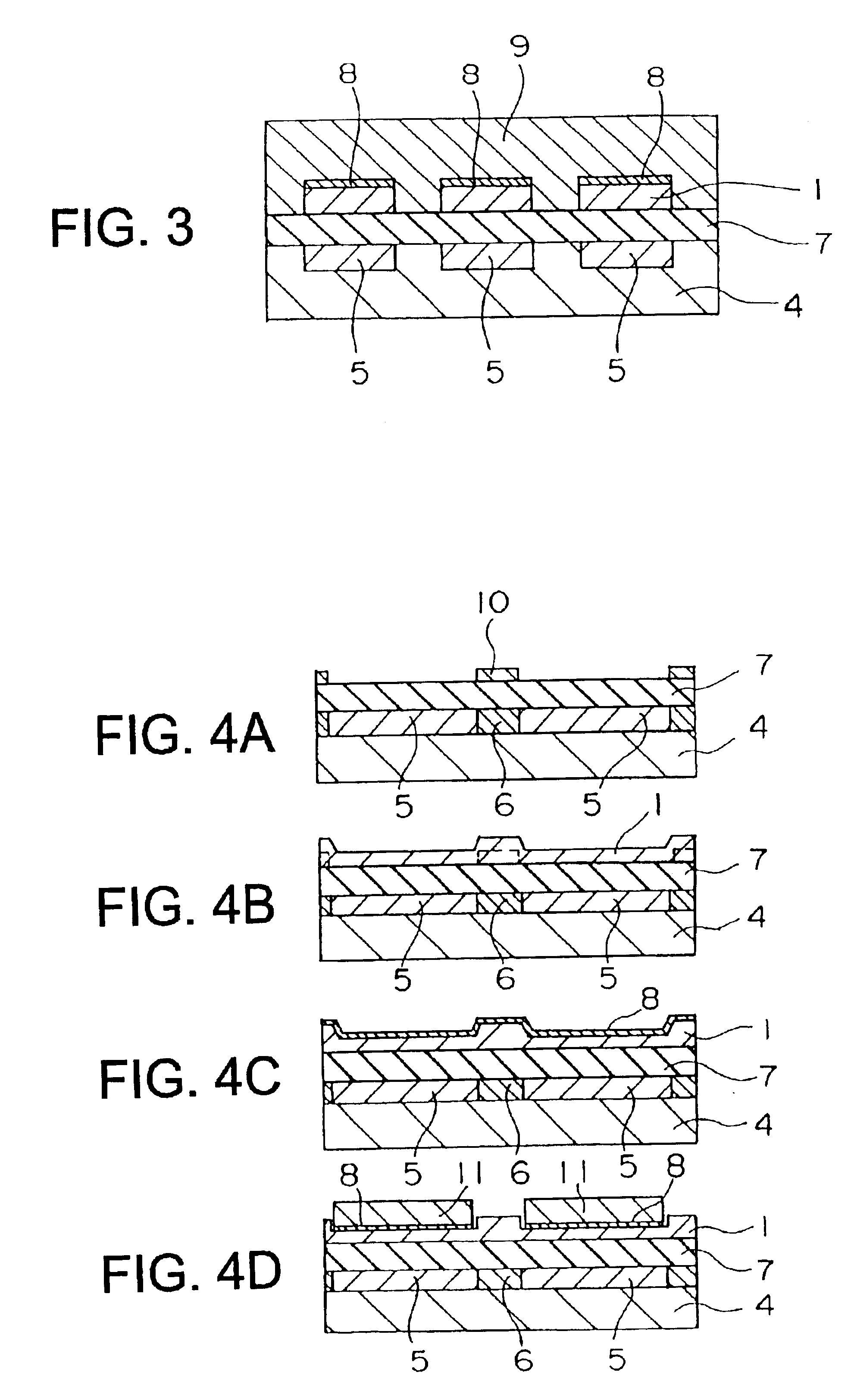

Hereinafter, the first embodiment of the present invention is described with reference to FIGS. 1 to 4.

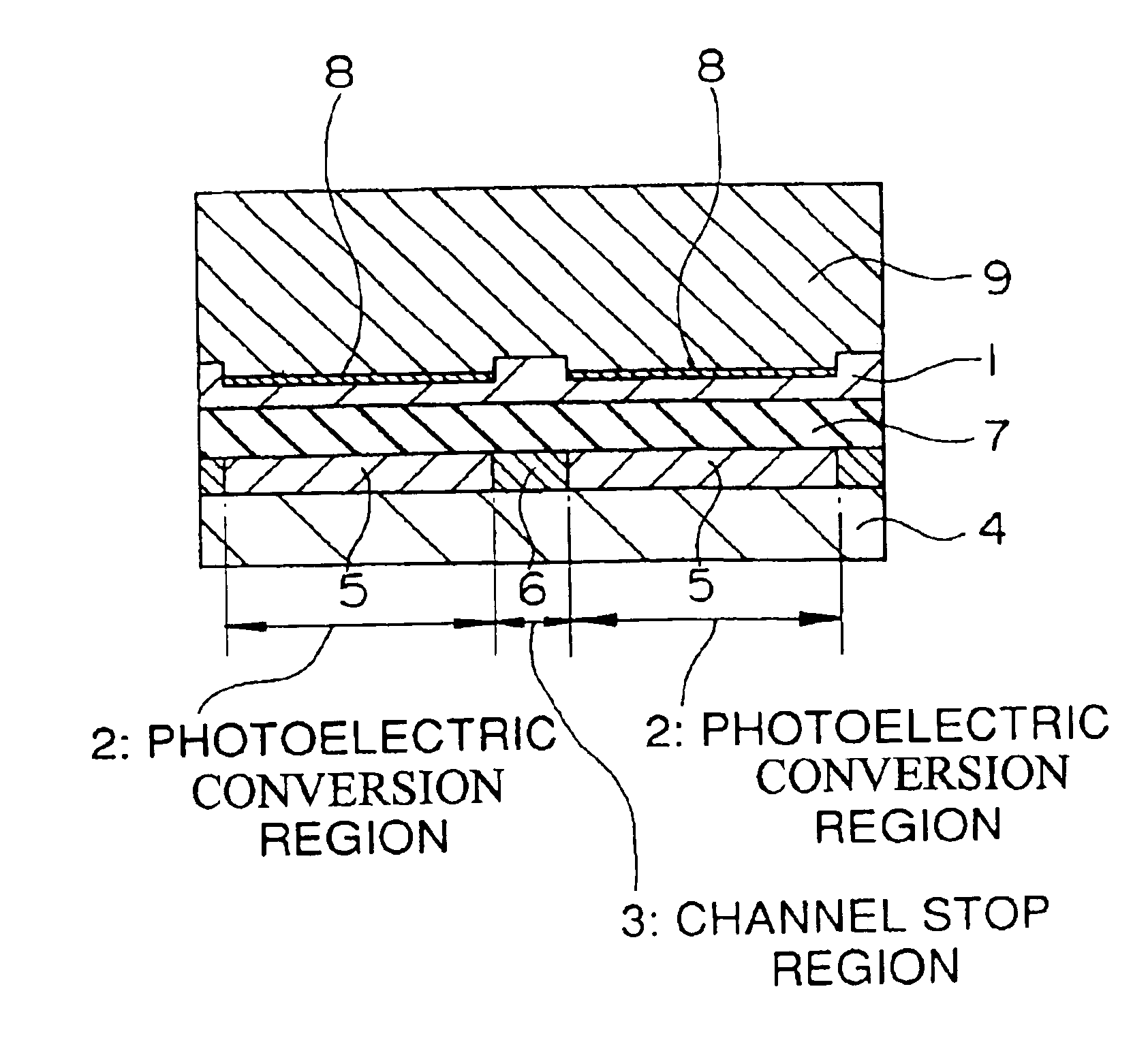

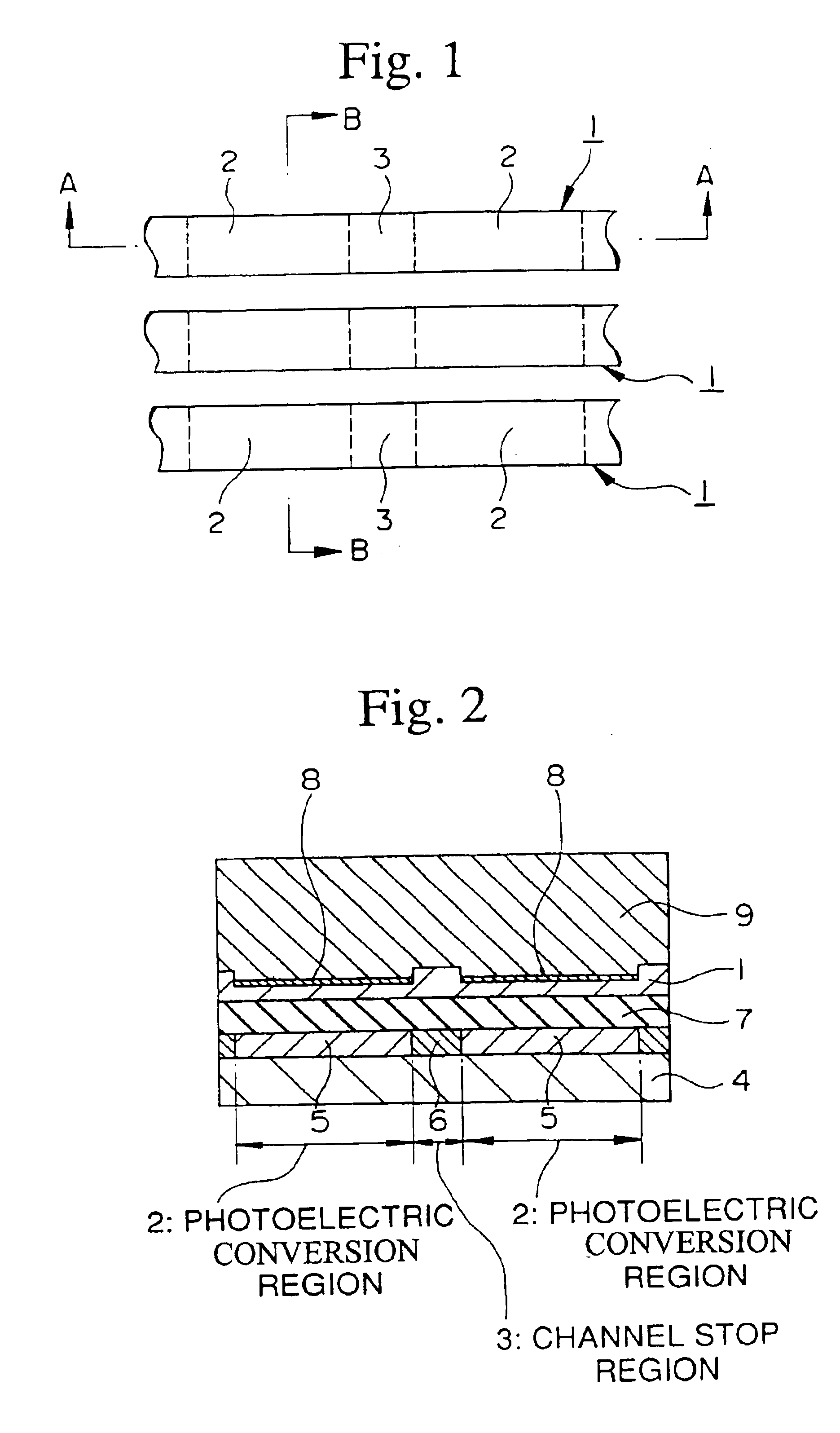

FIG. 1 is a planar view showing a structure, in particular to a structure of the light receiving portion of a CCD type solid imaging device according to the first embodiment of the present invention. FIG. 2 shows a cross-sectional diagram (along line A—A in FIG. 1), FIG. 3 shows a cross-sectional diagram (along line B—B in FIG. 1), and FIGS. 4A to 4D are cross-sectional diagrams showing the manufacturing process of the CCD type solid imaging device according to the first embodiment of the present invention.

As shown in FIG. 1, the light receiving portion of the CCD-type imaging device of the present invention comprises a plurality of transparent electrodes 1 extending to the lateral direction, a plurality of photoelectric conversion regions 2 along each transparent electrode, and a plurality of channel stop regions 3, each of which separates respective two photoele...

second embodiment

[Second Embodiment]

Hereinafter, the second embodiment of the present invention is described with reference to FIGS. 5 and 6A to 6D.

FIG. 5 is a cross-sectional diagram showing the frame transfer-type CCD-type solid imaging device according to the second embodiment of the present invention. FIGS. 6A to 6D are cross-sectional diagrams showing the manufacturing process of the CCD type solid imaging device according to the second embodiment of the present invention. Since the planar view and the cross-sectional view along the lateral direction of the transparent electrode are similar to those of the first embodiment, their illustrations are omitted. In FIGS. 5 and 6, the same components as those in FIGS. 2 and 4 are denoted by the same numerals.

In the CCD-type solid imaging device according to the second embodiment shown in FIG. 5, an N-type region 5 which constitutes the photoelectric conversion region 2 and a P+-type region 6 which constitutes the channel stop region 6 are formed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com