Chair construction

a chair and construction technology, applied in the field of chairs, can solve the problems of unsafe use, poor structural integrity of chairs, and a large amount of materials used, and achieve the effects of improving the aesthetics of the chair, and reducing the cost of us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

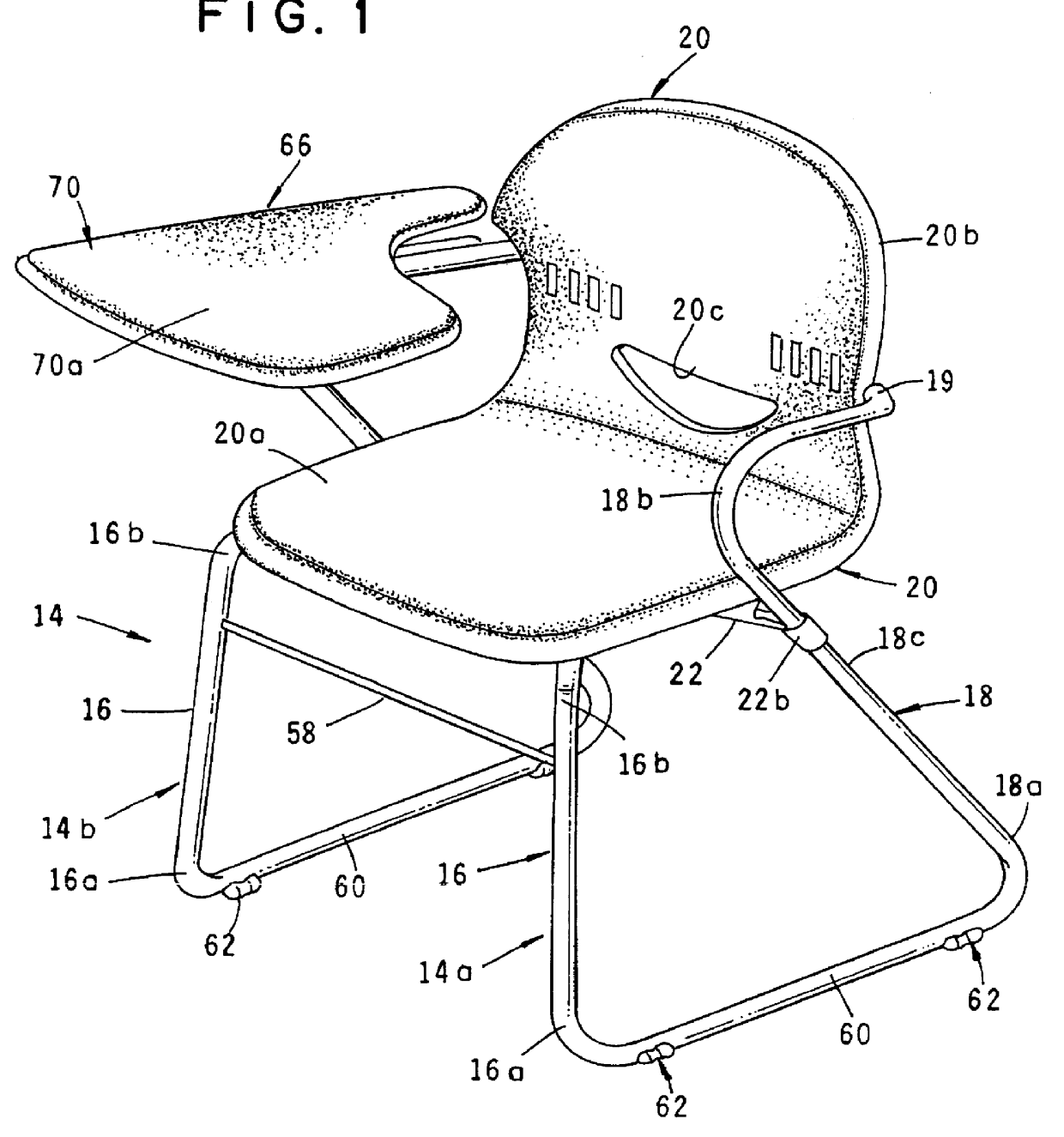

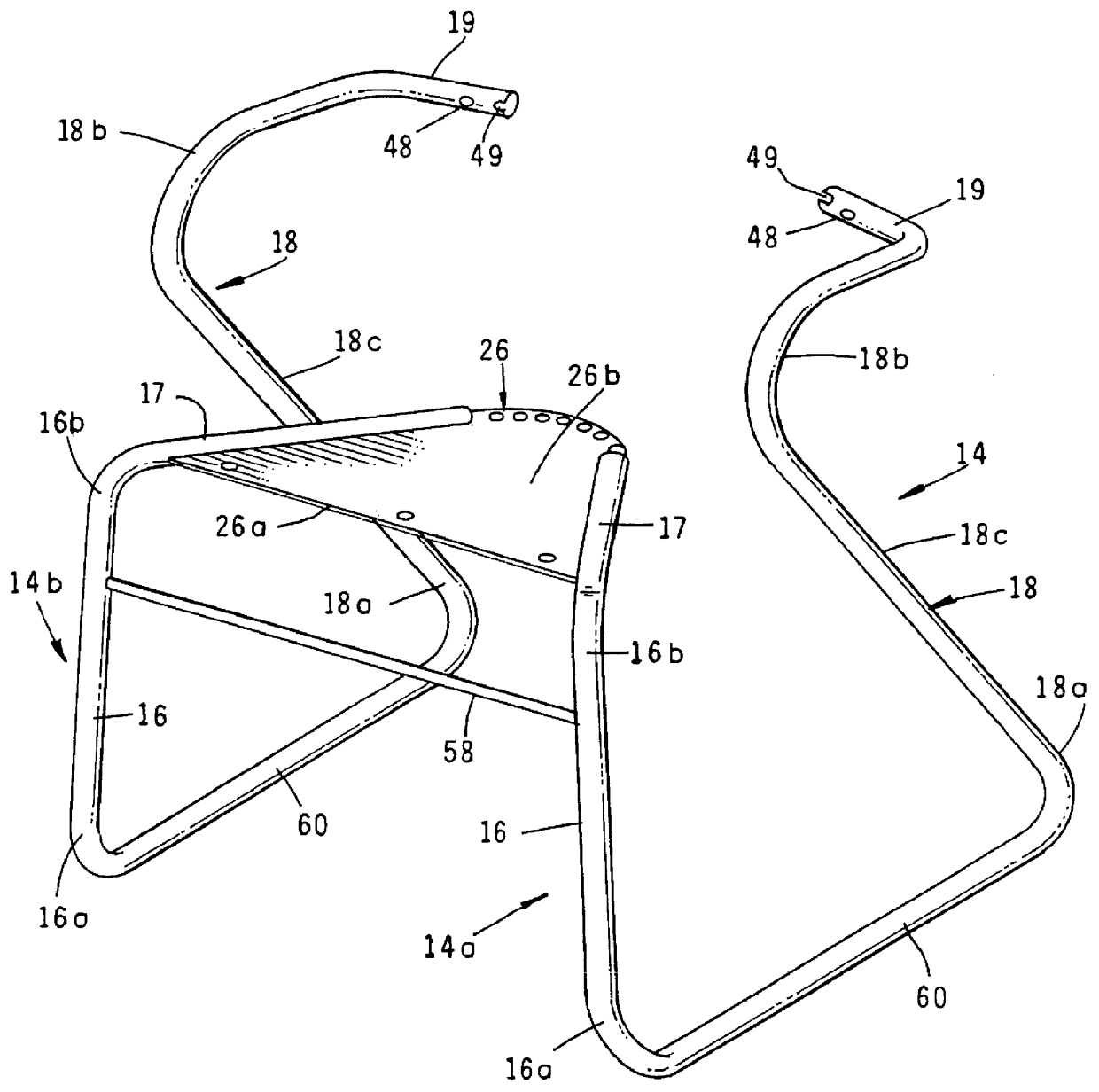

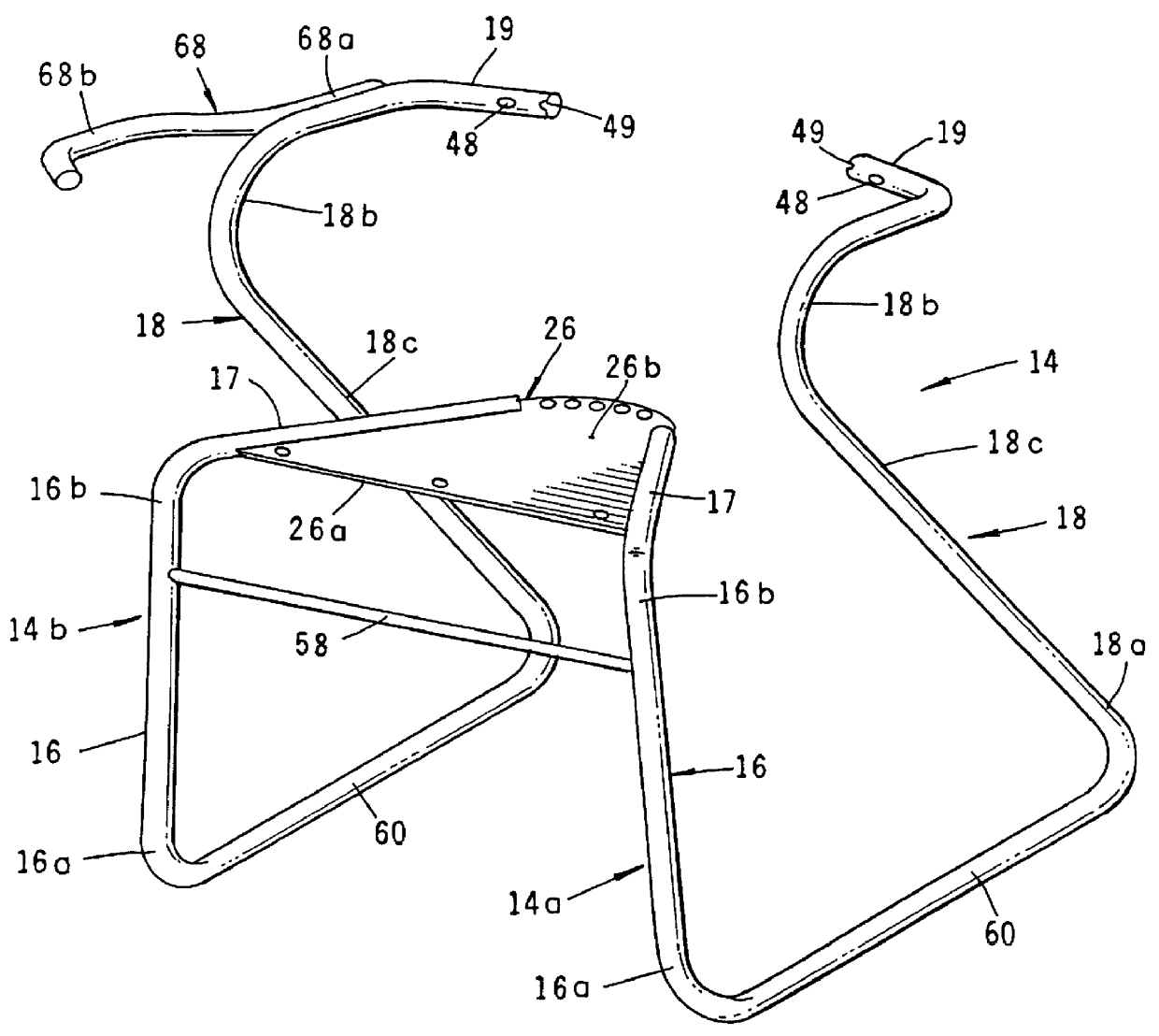

Referring to the drawings and in particularly to FIGS. 1 and 1A, one form of the chair construction of the present invention is there illustrated. As best seen in FIGS. 1A and 1B, the chair construction here comprises a supporting frame 14 having first and second sides 14a and 14b which are constructed of strategically bent metal tubing. Each of the sides 14a and 14b comprise a front leg 16 having a lower extremity 16a and an upper extremity 16b. Each upper extremity 16b include an inturned, rearwardly extending portion 17. Side portions 14a and 14b also include a rear leg 18 having a lower extremity 18a and an upper extremity 18b. Each of the upper extremities 18b includes an inturned, transversely extending portion 19 the purpose of which will presently be described. In one form of the invention, upper portions 18b of each side 18 comprise an arm rest which, as best seen in FIG. 1, is elevated from the seat portion 20a of a uniquely formed plastic molded, polypropylene shell 20, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Durability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com