Use of focused accelerated corrosion for metal decommissioning

a technology of accelerated corrosion and metal decommissioning, which is applied in the direction of electrolysis process, electrolysis components, etc., can solve the problems of high cost of cleaning of decommissioning metallic assets impacted by naturally occurring hazardous materials such as mercury, arsenic, lead and other contaminants, and generate a significant amount of wastewater, so as to achieve the effect of reducing the redox potential

Pending Publication Date: 2022-10-06

CHEVRON AUSTRALIA PTY LTD +2

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

This invention relates to a method for controlled uniform corrosion using a metallic asset as a sacrificial anode and a cathode assembly of lower redox potential. A non-conductive permeable spacer and an electrolytic conducting fluid complete the circuit. The method can remove unwanted materials from various areas across the surface of the metallic asset with a preferred embodiment of up to 0.1 mm thickness in one minute or less. Additionally, a magnetized moveable brush heads can be used for focused corrosion of different areas. The method can also increase the temperature of the conducting fluid or alter the electrolytic chemistry to increase the reaction rate. These technical effects accelerate the corrosion process.

Problems solved by technology

Decommissioning metallic assets that have been impacted with naturally occurring hazardous materials which may include mercury, arsenic, lead and other contaminants have been traditionally costly to clean.

This process typically generates a significant amount of wastewater and makes slow progress.

As a result, this process generates a large volume of acidic waste.

Decommissioning of Subsea Pipelines can be prohibitively expensive if pipeline removal is required.

If removal of these types of pipelines and facilities is necessary, then the presence of impregnated metals and other impurities can add significant costs to the removal and disposal.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 1

l Resistance is Reduced as Dry Steel Becomes More Saturated During Treatment

[0026]4 areas treated sequentially, 2 minutes each area. Treatment began on dry steel surface at Area 1, water flooding of all areas commenced at the beginning of treatment. Current density can be increased for the same power usage by pre-wetting the steel.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| corrosion | aaaaa | aaaaa |

Login to View More

Abstract

The present invention is directed to a method of using accelerated corrosion to remove metallic assets.

Description

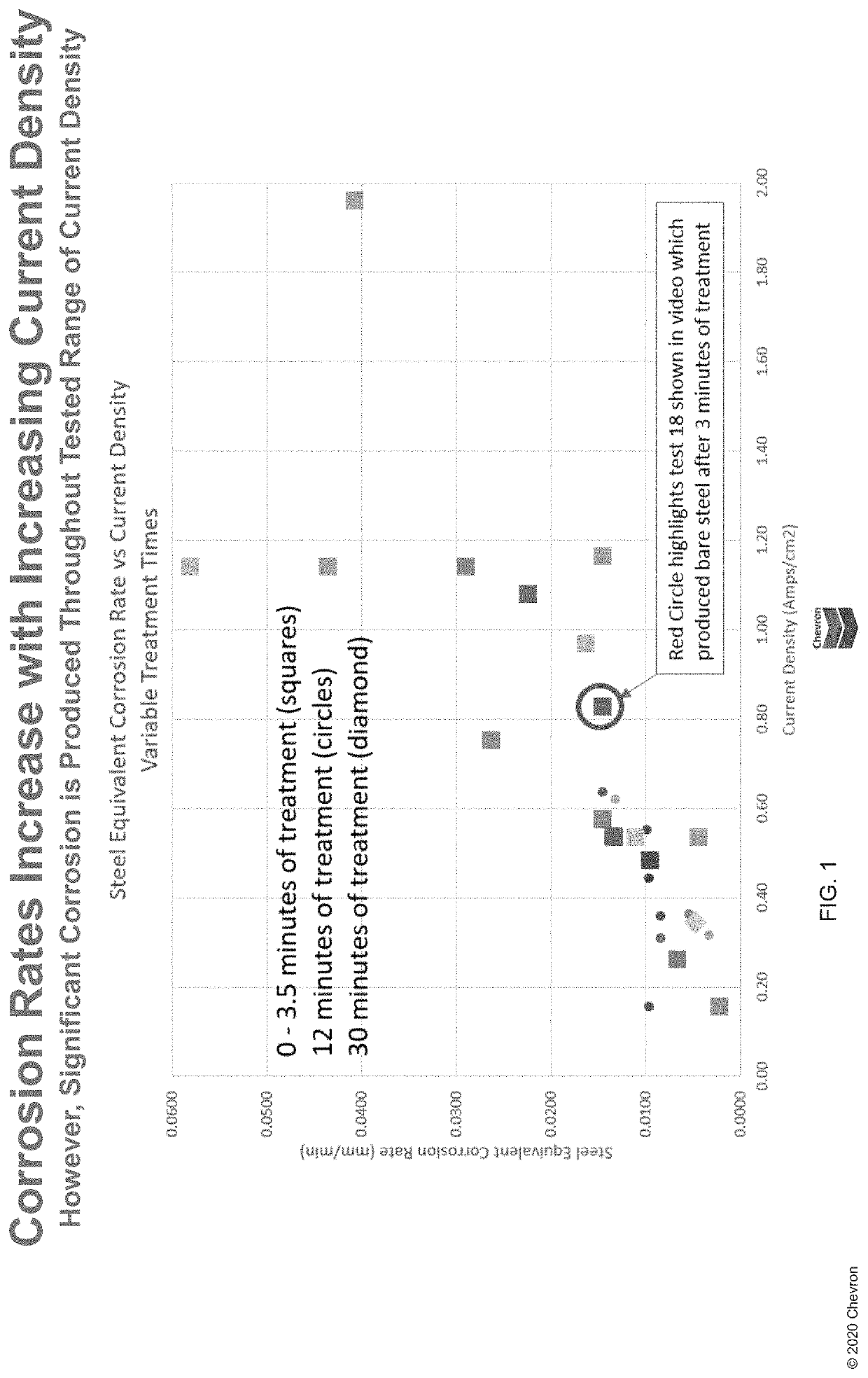

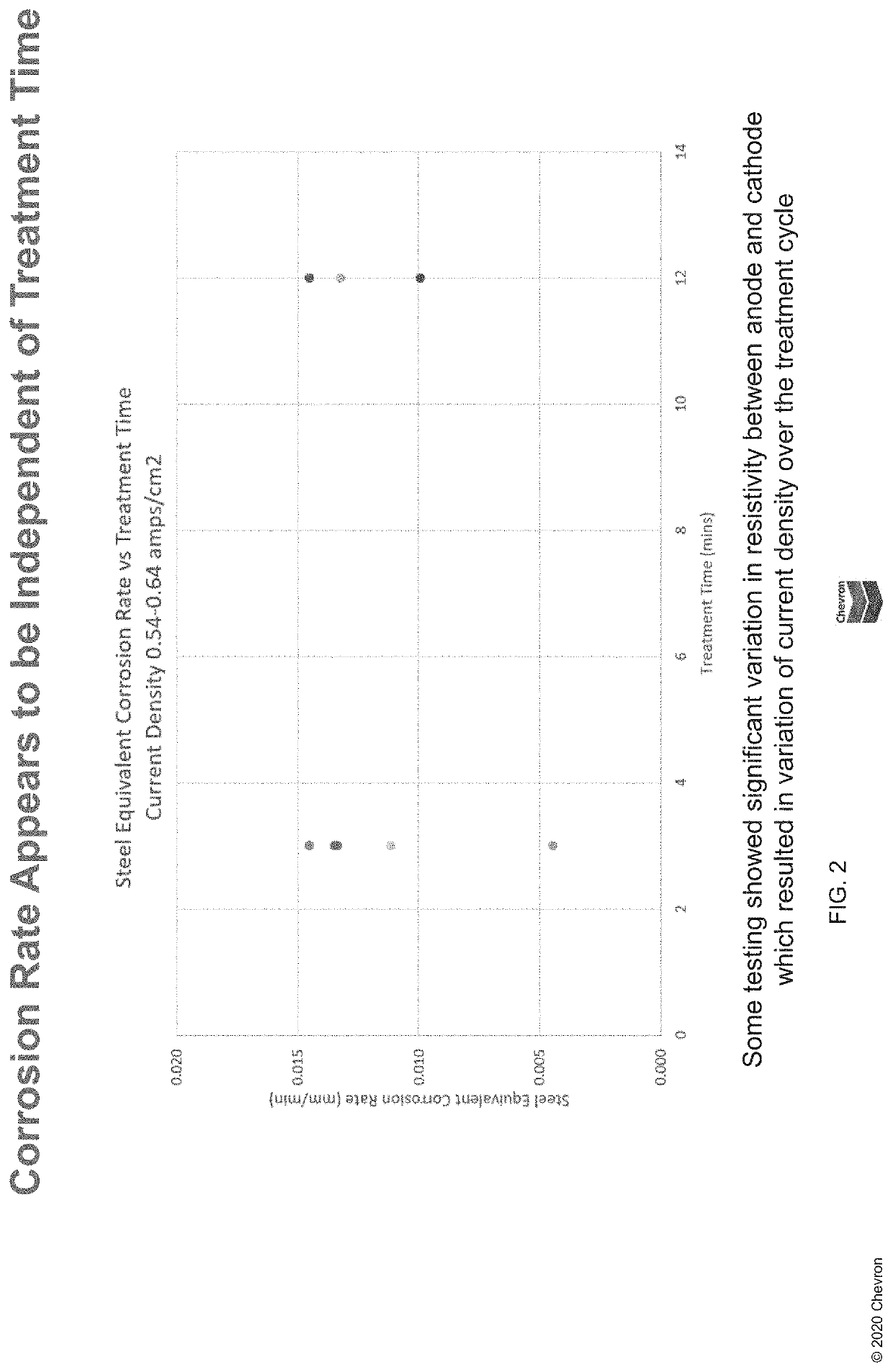

FIELD OF THE INVENTION[0001]This invention relates to a method of accelerated controlled uniform corrosion of a focused area of a metallic asset.BACKGROUND OF THE INVENTION[0002]Decommissioning metallic assets that have been impacted with naturally occurring hazardous materials which may include mercury, arsenic, lead and other contaminants have been traditionally costly to clean. These materials are often found embedded within the surface scale or corrosion layer. Standard industry practice to remove these materials can be achieved physically or chemically. The physical approach uses high pressure water jets to detach the surface scale or corrosion from the asset. This process typically generates a significant amount of wastewater and makes slow progress. The chemical approach commonly uses acidic chemistries that dissolved the inorganic scale or corrosion material. As a result, this process generates a large volume of acidic waste. U.S. Ser. No. 10 / 181,706 describes a method to re...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(United States)

IPC IPC(8): C23F4/00

CPCC23F4/00C25F3/06C25F7/00C23F2213/32C25F1/06

Inventor THOMAS, DAVID GLYNNSRIWATTANA, PERAPONBIRETA, PAULAKINPELU, ADEBAYOHERNANDEZ, SANDRA

Owner CHEVRON AUSTRALIA PTY LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com