High speed paper web turn-up system with a prepared length paper band coil

a paper web and coil technology, applied in paper-making, textiles and paper, thin material processing, etc., can solve the problems of reducing the efficiency of paper making machines, halting the paper machine involved, and converting moving paper to scrap, so as to achieve rapid change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

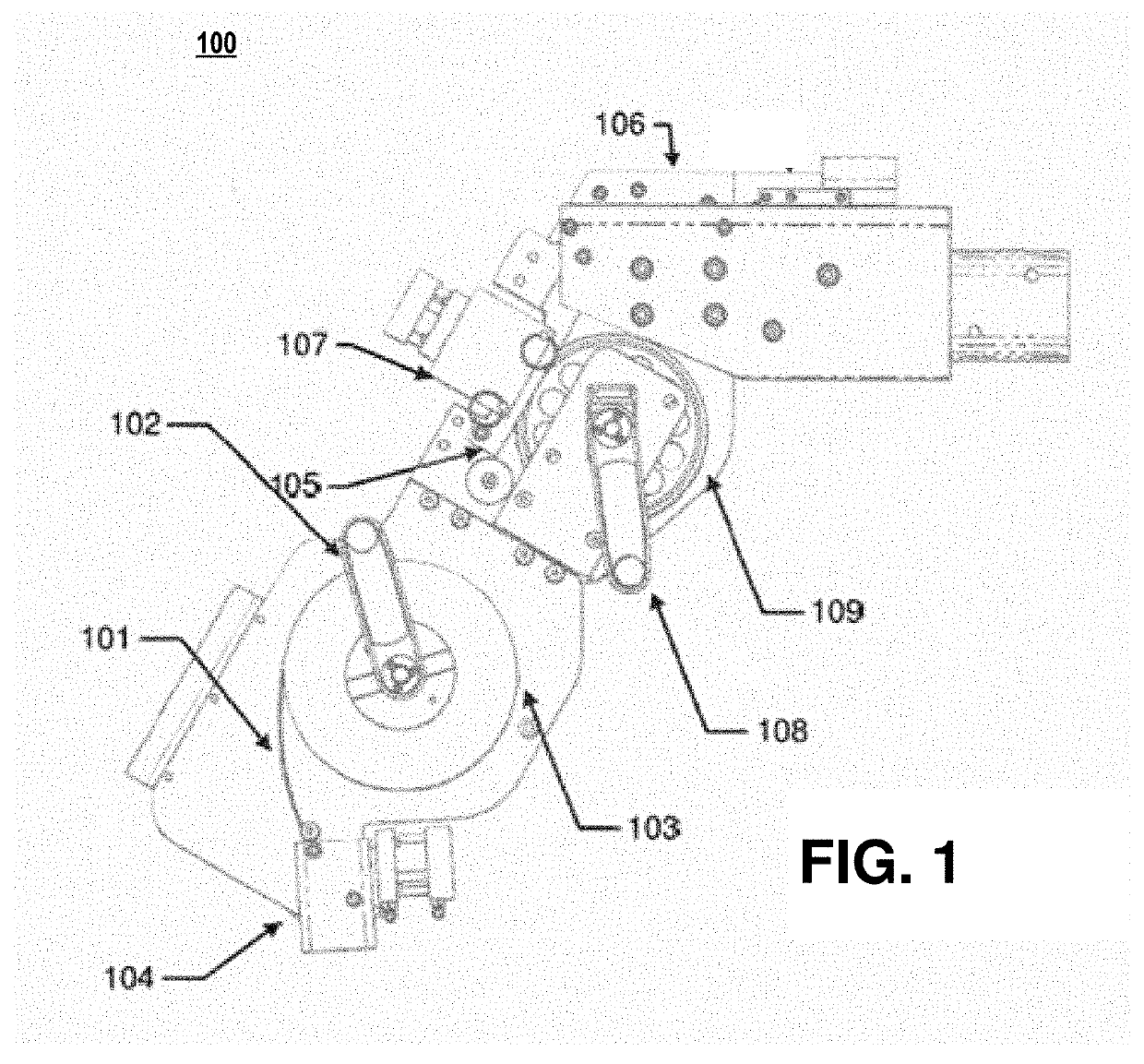

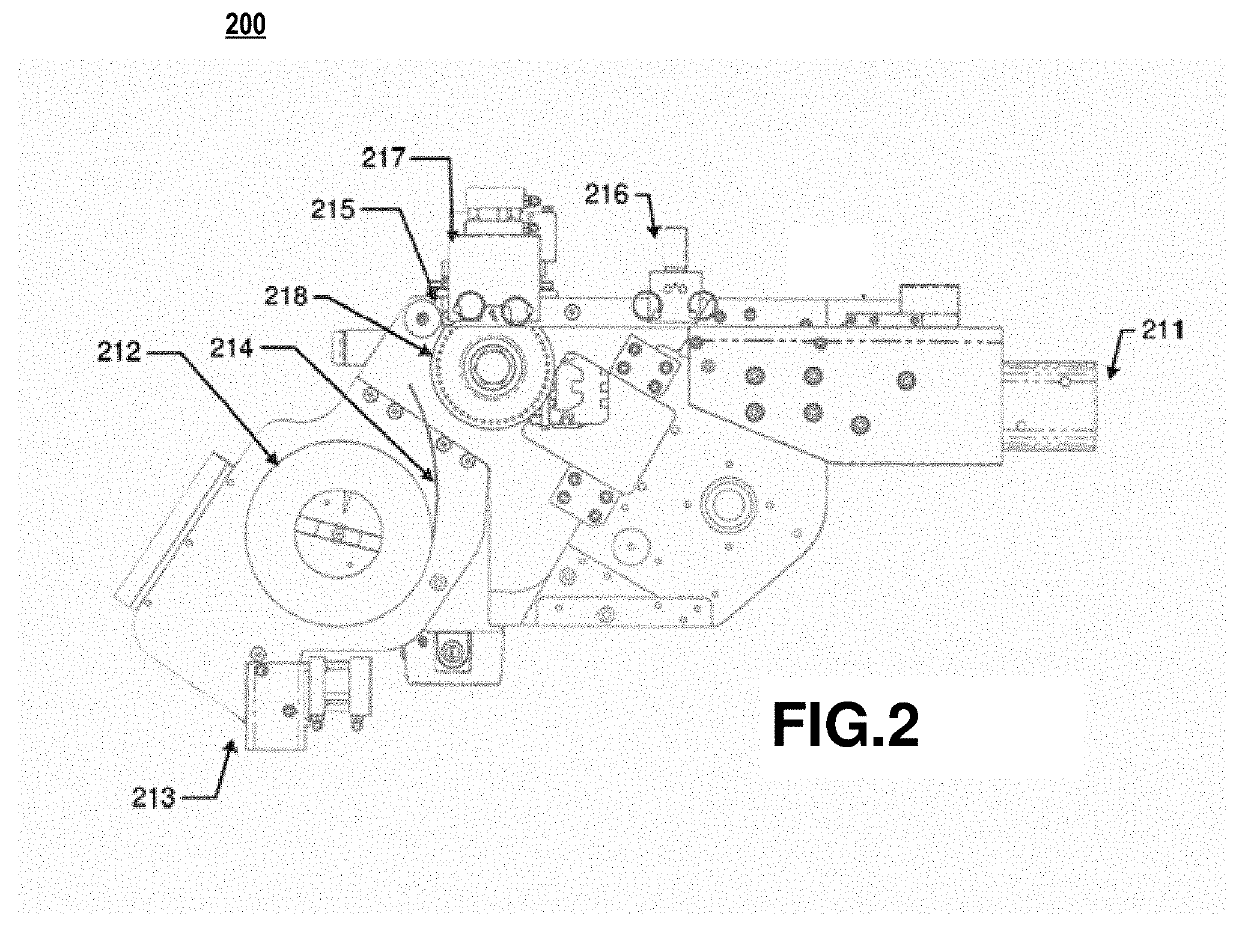

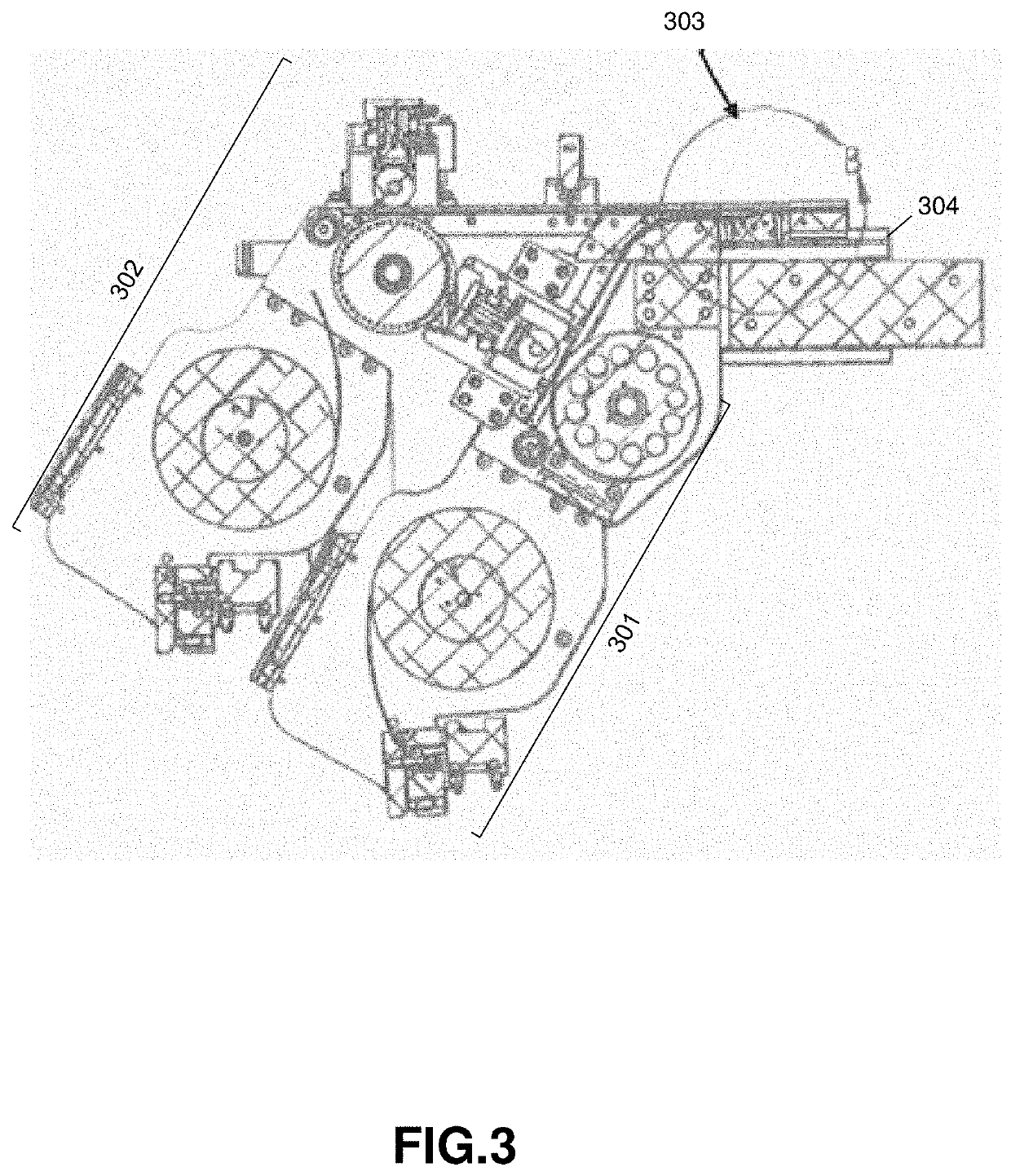

[0058]The present invention relates generally in a first sense to the field of devices, apparatus, systems, and methods of effecting paper machine turn up process involving high-speed severing and transfer of a rapidly advancing paper web from a rotating spool fully wound with paper onto an empty rotating spool. More particularly the present invention includes an improved paper band delivery assembly for reliable high speed delivery of a turn-up paper band across a moving web of paper being manufactured on a paper machine and wound onto a spool. The turn-up paper band is made ready for a turn up procedure by coiling a predetermined length of paper band suitable for a particular machine and retaining the coiled paper band in a reservoir pending deployment across a spool for a turn up procedure. The paper band may be coiled via manual operation or via automated operation. The coiled paper band may be supported within the reservoir on rollers, pins, or other items conducive to fast and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com