Tire vulcanization mold and pneumatic tire

a technology of pneumatic tires and molds, which is applied in the direction of tires, vehicle components, domestic applications, etc., can solve the problems of inability to provide the effect of suppressing the rubber from being caught at the fitting portion, the position and shape of the protrusion have not been studied in detail, etc., to achieve the effect of suppressing the rubber from being caught, maintaining the aesthetic appearance of the tire, and suppressing the occurrence of poor appearance of the pneumatic tir

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings.

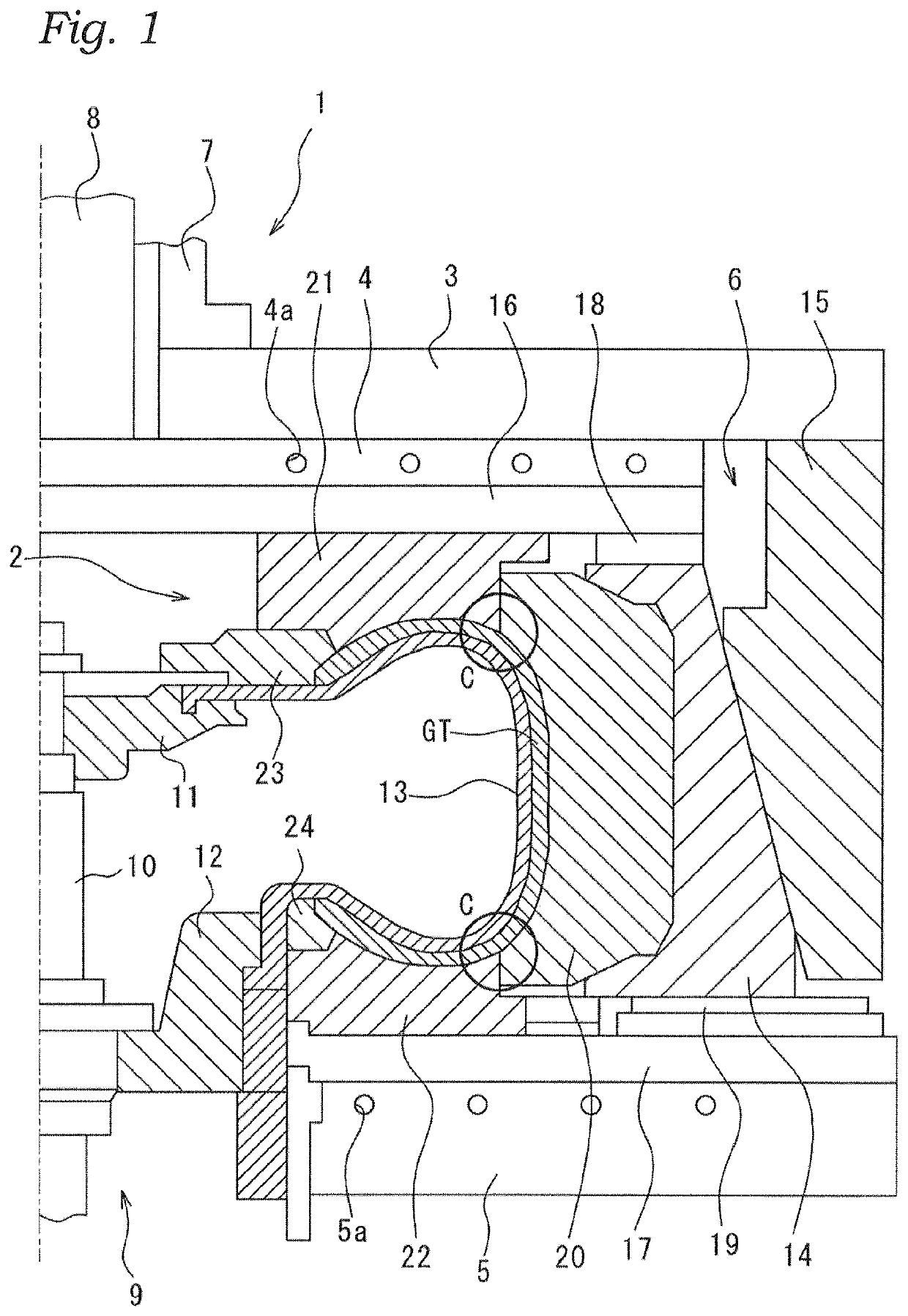

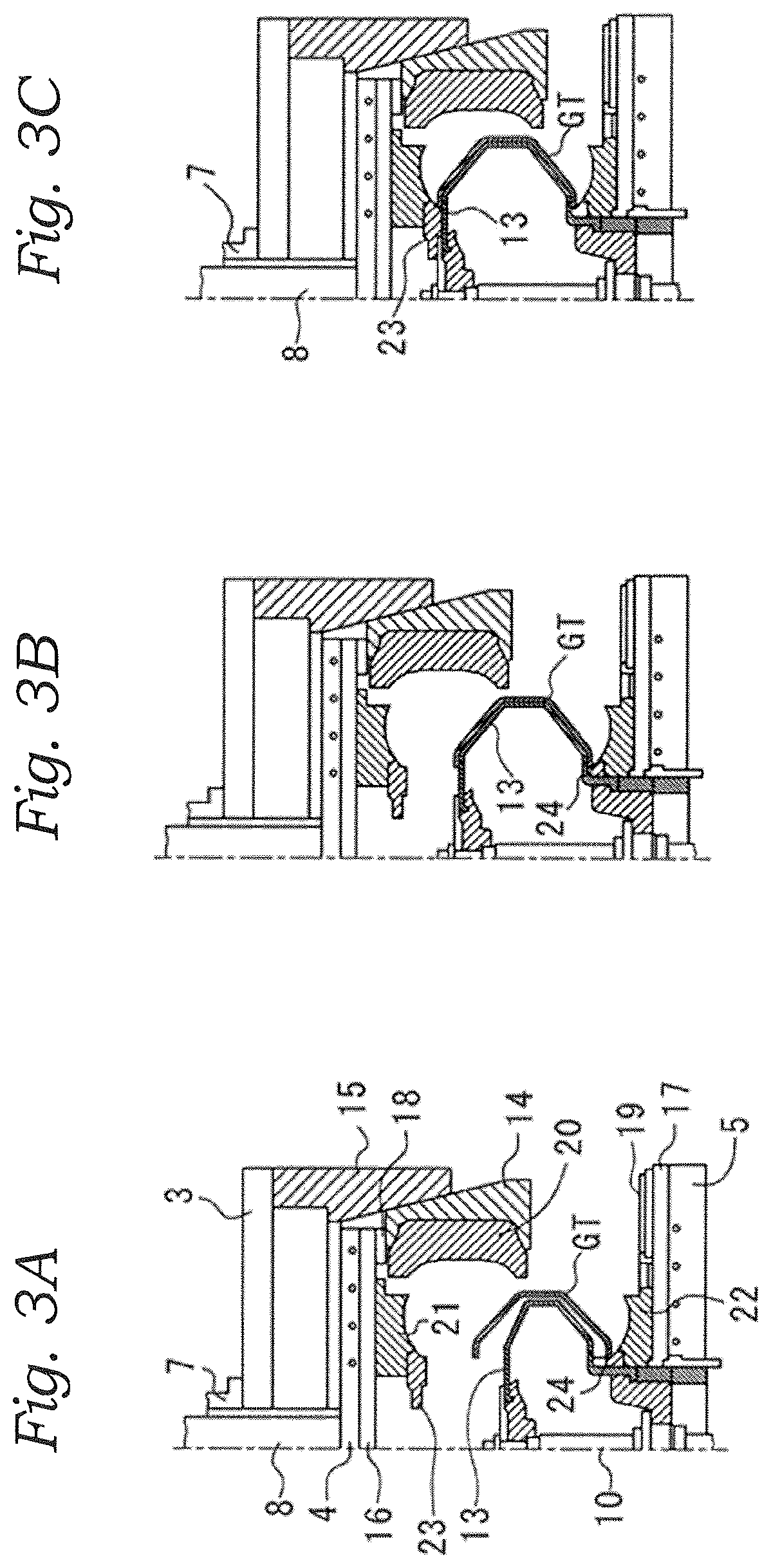

[0028]FIG. 1 shows a state in which a tire vulcanization mold 2 according to the present embodiment is attached to a vulcanization molding machine 1. The tire vulcanization mold 2 is attached via a container 6 between an upper plate 3 and an upper platen 4 of the vulcanization molding machine 1, and a lower platen 5.

[0029]The upper plate 3 is fixed to the lower end of a lifting cylinder 7. A lifting rod 8 is disposed at the center of the lifting cylinder 7. The upper platen 4 is fixed to the lower end of the lifting rod 8. The lifting cylinder 7 and the lifting rod 8 are moved up and down by a driving device (not shown). The upper plate 3 and the upper platen 4 are configured to be able to move up and down independently. A flow path 4a is formed in the upper platen 4. The temperature can be adjusted by the flow of a heat exchange medium (for example, oil) in the flow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

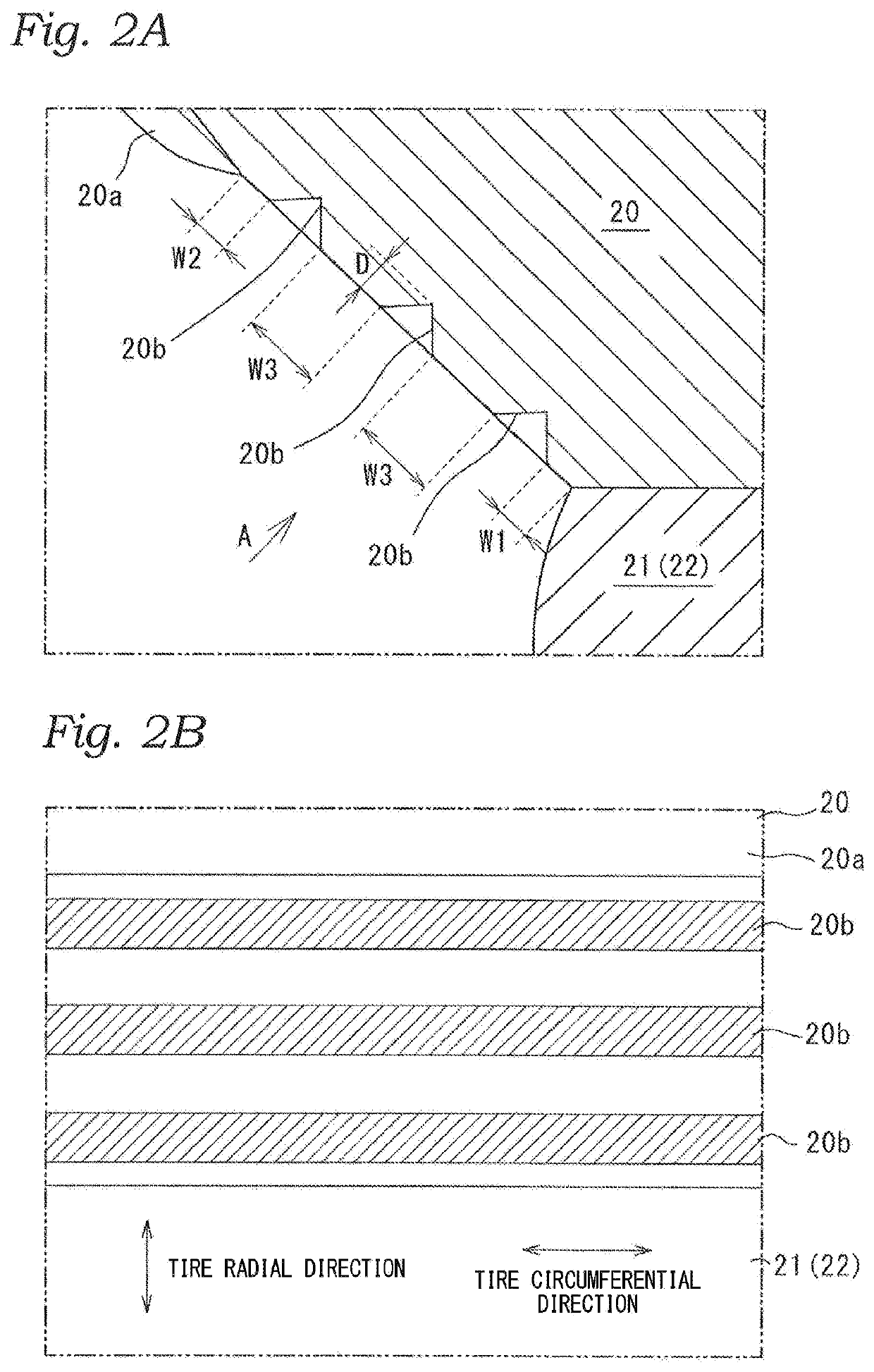

| width W1 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com