Seawall using screw piles

a technology of screw piles and seawalls, applied in the field of seawalls, can solve the problems of limited sediment exchange between land and sea, high cost of manufacture and installation of seawalls constructed in this manner, and the inability of suitable equipment for casting concrete grade beams in place to access many remote areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

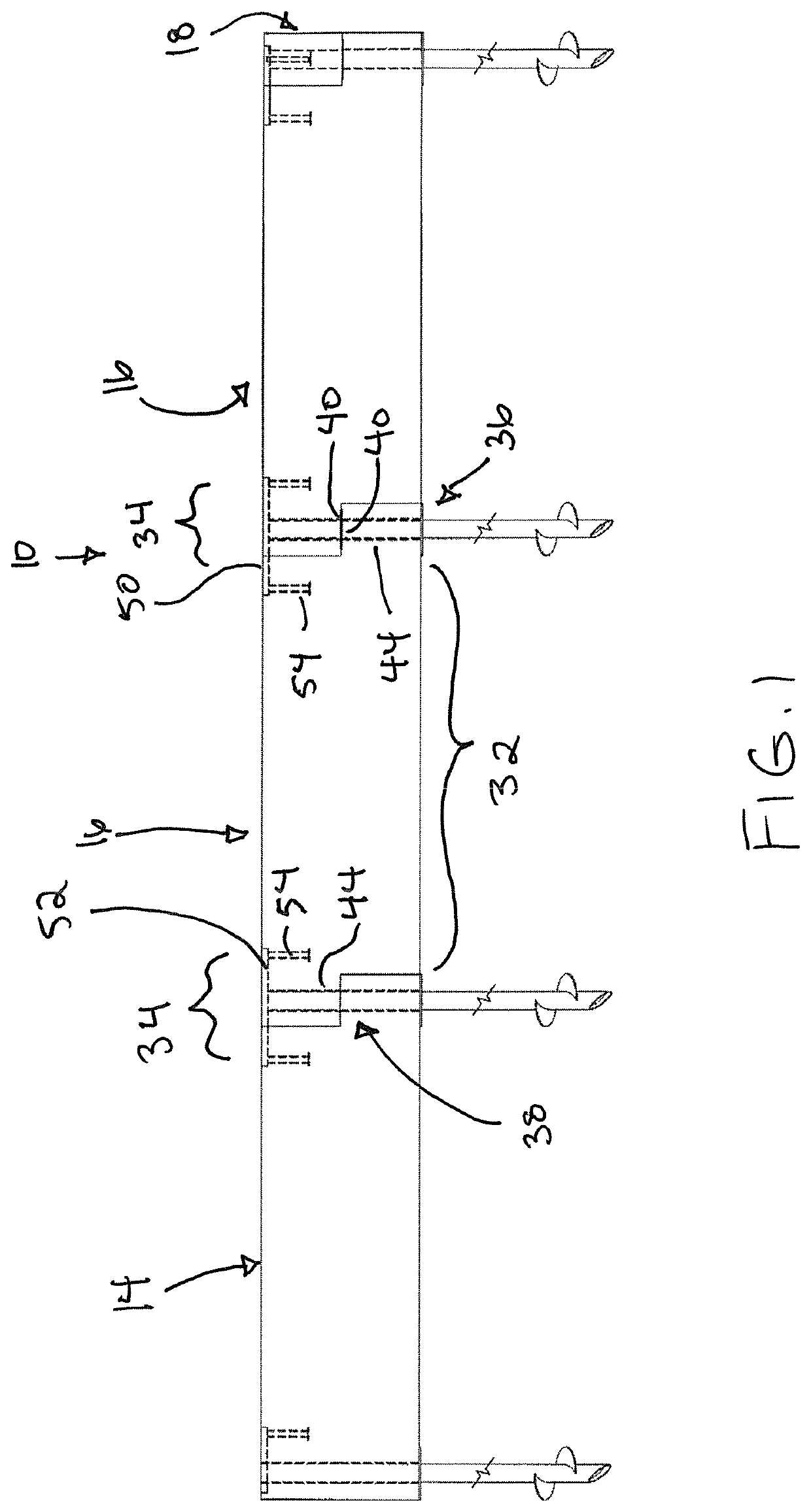

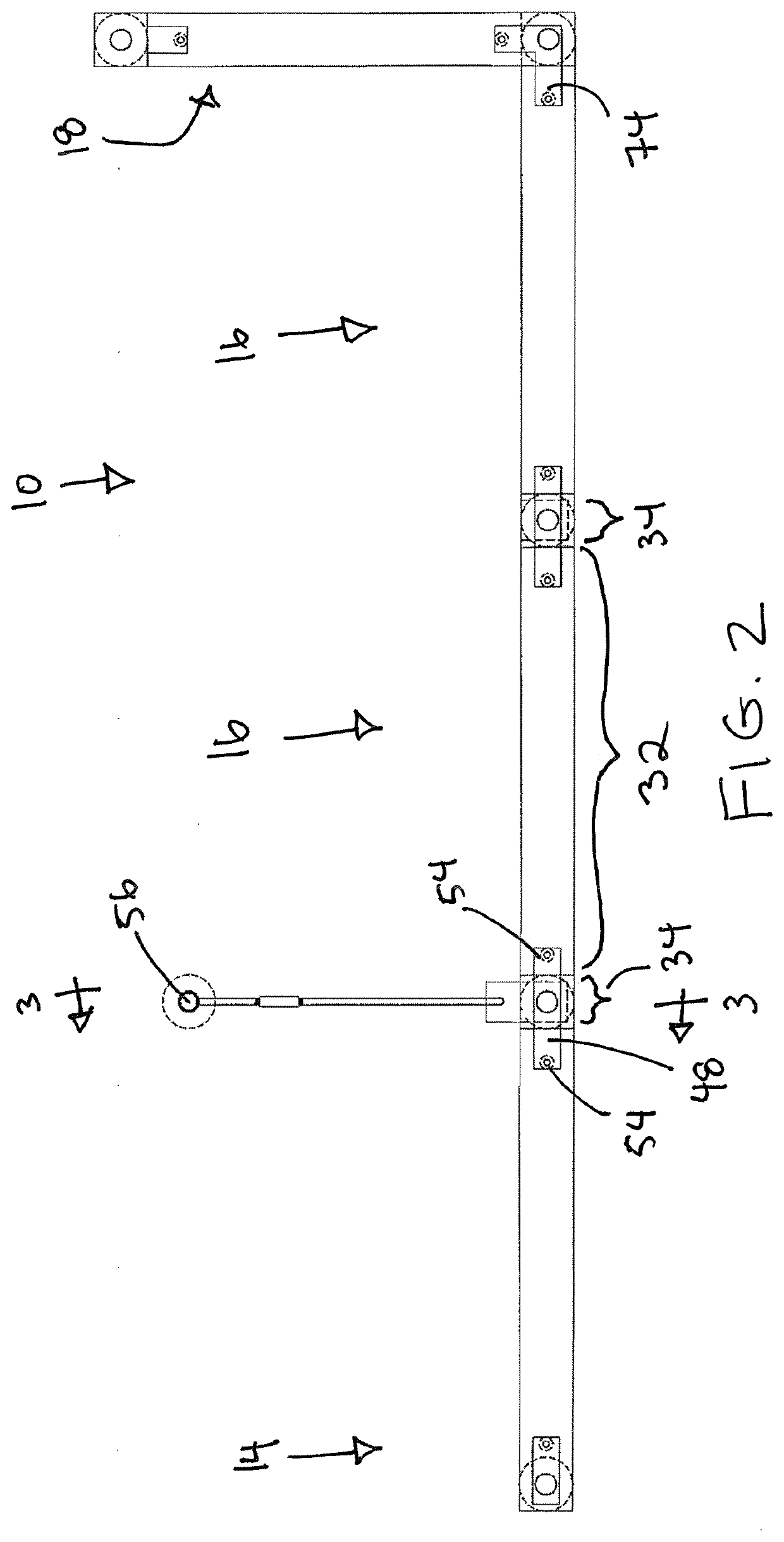

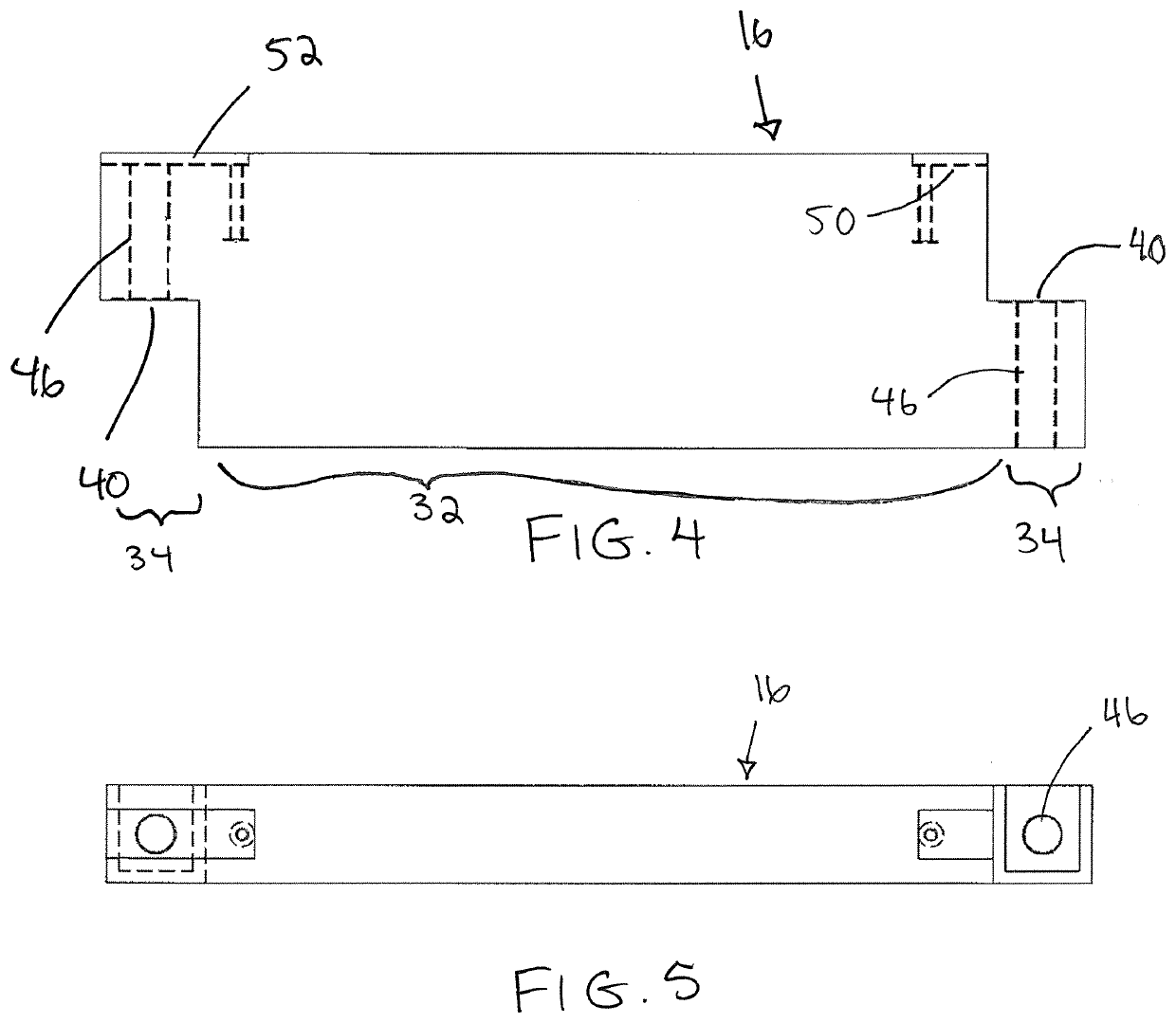

[0034]Referring to the accompanying figures there is illustrated a seawall generally indicated by reference numeral 10. The seawall 10 is particularly suited for being supported on a seabed 12 along a coastline using an assembly of modular components including anchoring components penetrated into the seabed and wall components protruding upwardly from the seabed while remaining partly or fully submerged in the sea.

[0035]The seawall assembled from a plurality of wall panels which are arranged for being connected in series with one another along the boundary formed by the seawall. The modular wall panels include (i) an end panel 14 located at one or both ends of the seawall, (ii) a plurality of intermediate panels 16 which are connected end to end with one another within a generally common plane for use along a majority of the wall boundary between opposing ends of the assembled seawall, and (iii) optionally one or more corner panels 18 used for joining two adjacent panels at right an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com