Method for evaluating and controlling temperature influence on a homogeneity test for infrared optical materials

a technology temperature influence, which is applied in the direction of optical apparatus testing, instruments, structural/machine measurement, etc., can solve the problems of invalid test, serious distortion of test results of infrared optical materials, and inability to realize high-precision tests only by high-precision equipment and high-precision methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]The present invention will be further described in detail with reference to the accompanying drawings and embodiments, from which the purpose, content and advantages of the present invention will be clearer.

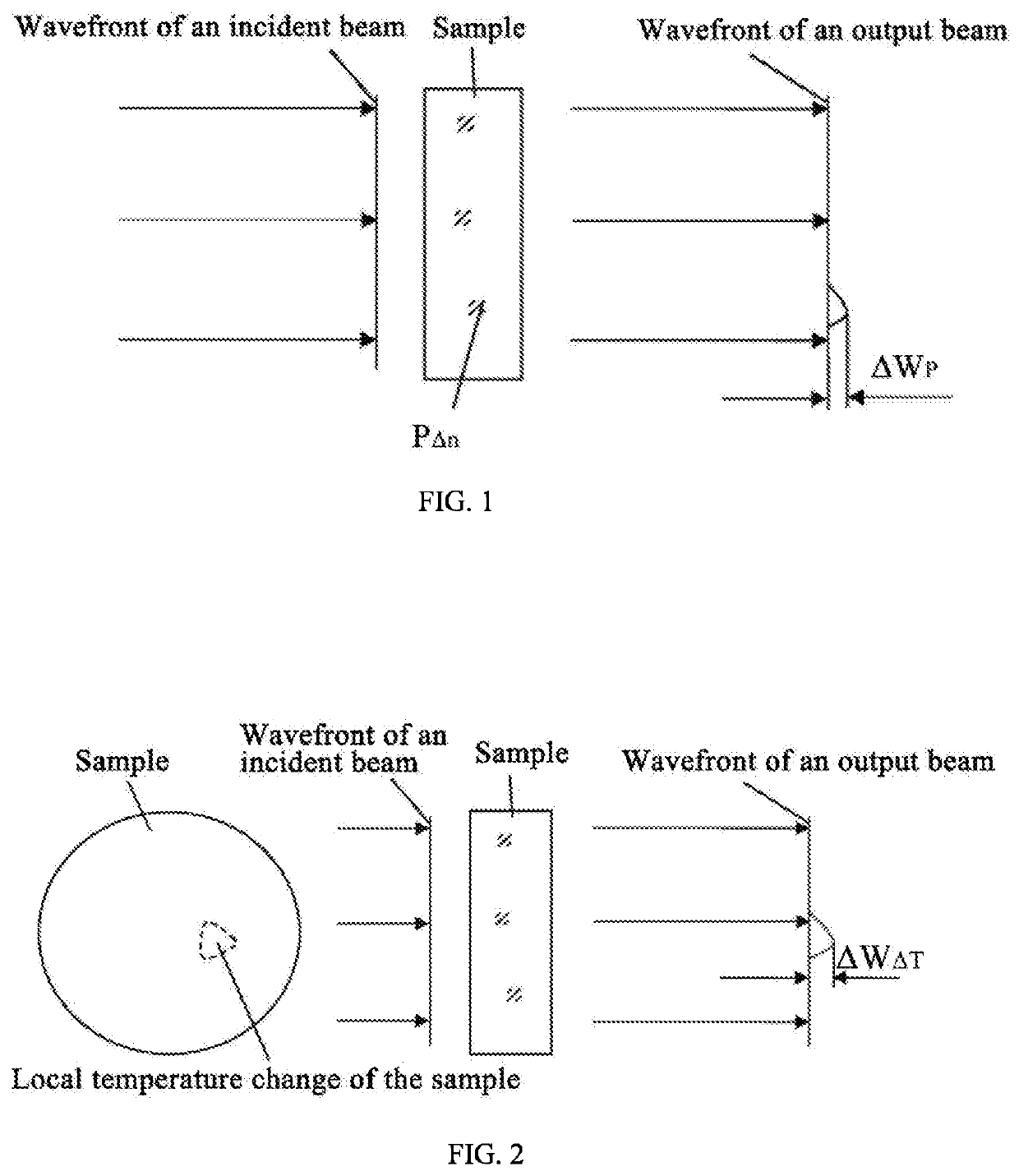

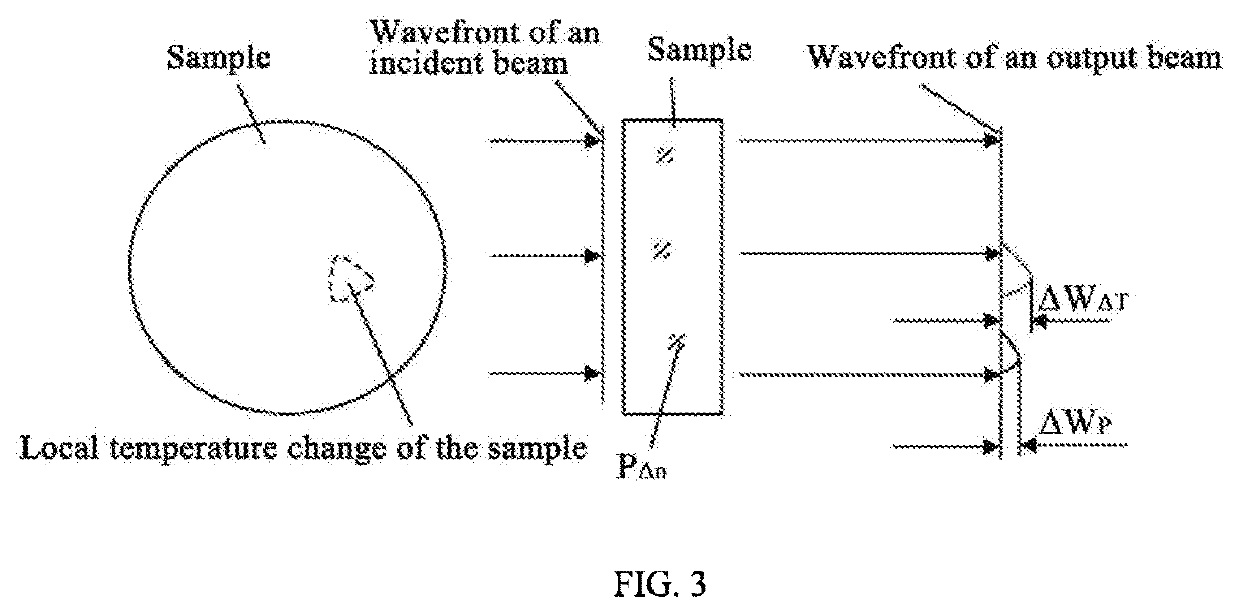

[0027]The precision of a test result is seriously affected by small local temperature changes of a sample during the homogeneity test of refractive index. The present invention establishes a two-dimensional numerical table in which the test precision requirements of a refractive index test of infrared optical materials and the ambient control temperatures corresponding to the influence of temperature changes on the refractive index of different infrared optical materials, and related calculation formulas are established. In addition, related calculation formulas are established for theory analysis, numerical calculation and table-designing. Therefore, the present invention provides a method for evaluating and controlling temperature influence on a homogeneity test for infra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com