Blends of oligopeptide terminal polyisobutylene or polystyrene

a technology of oligopeptides and terminal polyisobutylenes, applied in the direction of coatings, etc., can solve the problems of creeping material form instability, damage may heal, inadequate for others, etc., and achieve excellent vibration damping properties, excellent energy dissipation and damping properties, and useful vibration damping properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

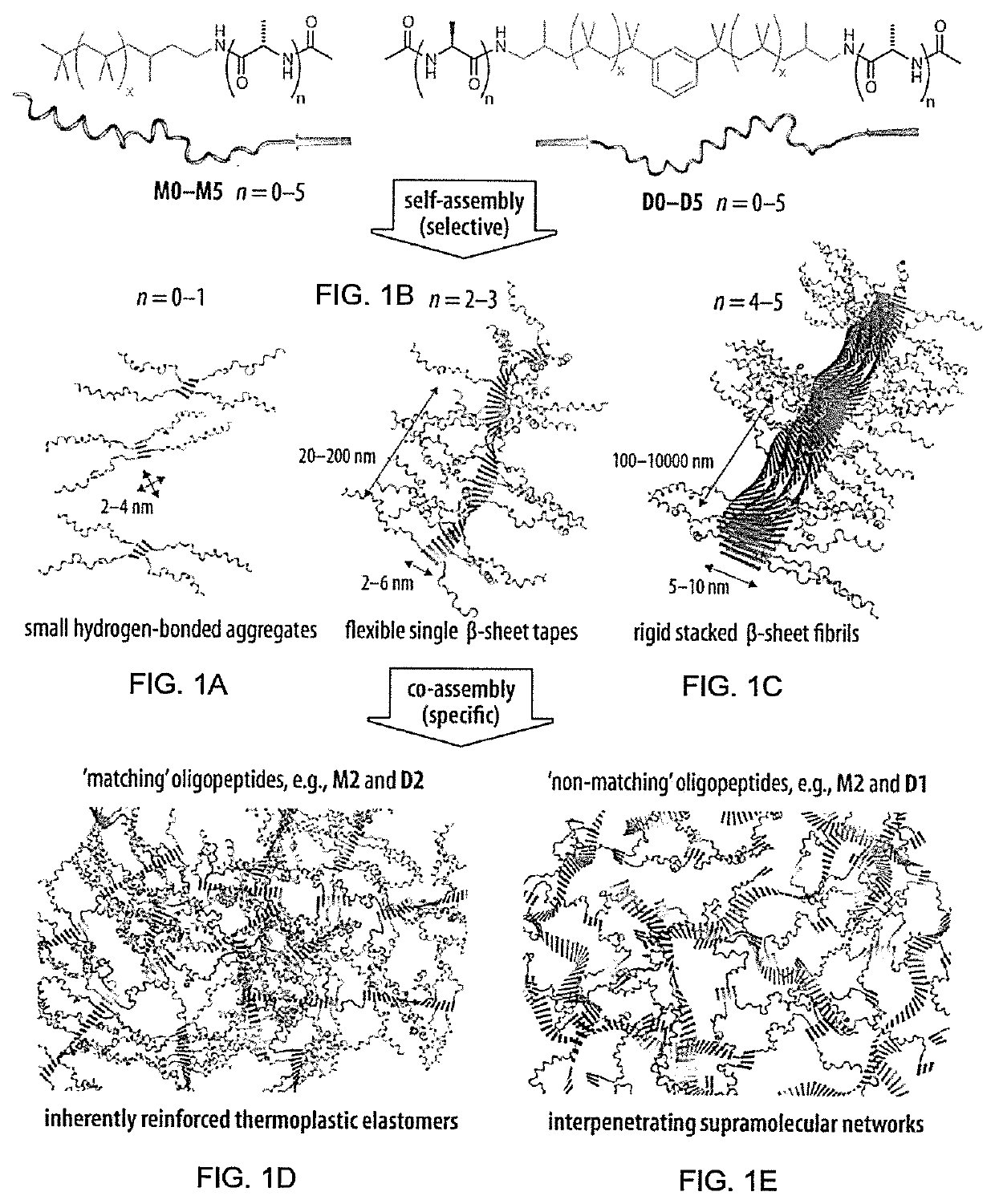

[0080]As shown in the drawings and referring in particular to FIGS. 1A, 1B, 1C and 1D:

[0081]FIGS. 1A, 1B and 1C provide Schematic illustration of the selective self-assembly of the monofunctional oligo(L-alanine)-modified poly(isobutylene)s M0-M5 (n=0-5; x 20) and the corresponding difunctional derivatives D0-D5 (n=0-5; x 20) into small hydrogen-bonded aggregates, flexible single β-sheet tapes, or rigid stacked β-sheet fibrils. The coexistence of these nanostructures in blends of molecules with different oligopeptide termini resulted in ‘inherently reinforced thermoplastic elastomers’ (see FIG. 1D) or ‘interpenetrating supramolecular networks’ (see FIG. 1E).

[0082]Differently from all previous examples of supramolecular networks, the aggregation of the oligopeptide-terminated polymers that constitute the basis of the present invention that comprise chiral and monodisperse (molecularly defined) oligopeptides as hydrogen-bonded ligands results in a highly selective formation of small h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| lengths | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com