Telescoping jack for lifting large capacity trucks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0090]In the following description, details are set forth to provide an understanding of the application. In some instances, certain structures, techniques and methods have not been described or shown in detail in order not to obscure the application.

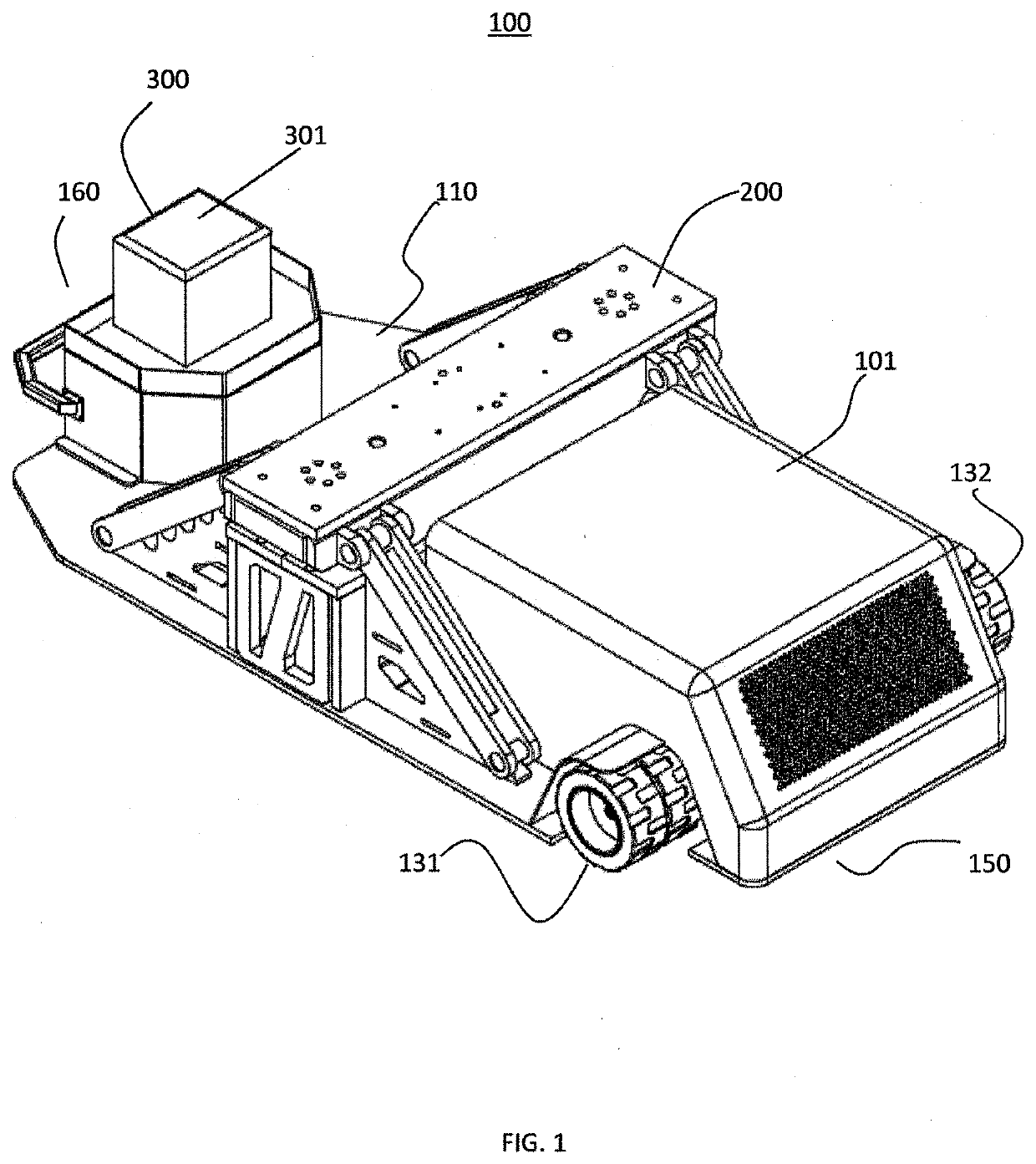

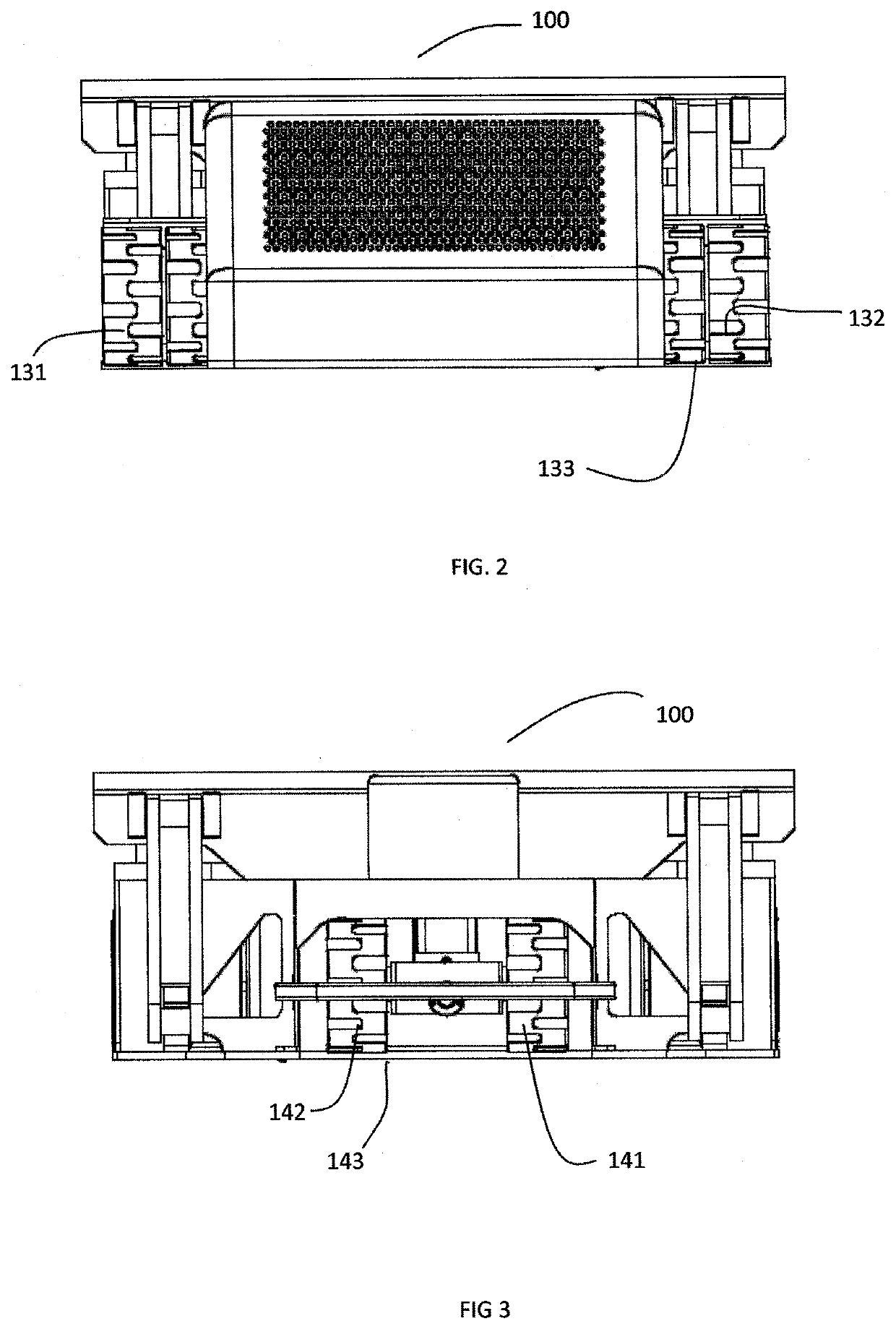

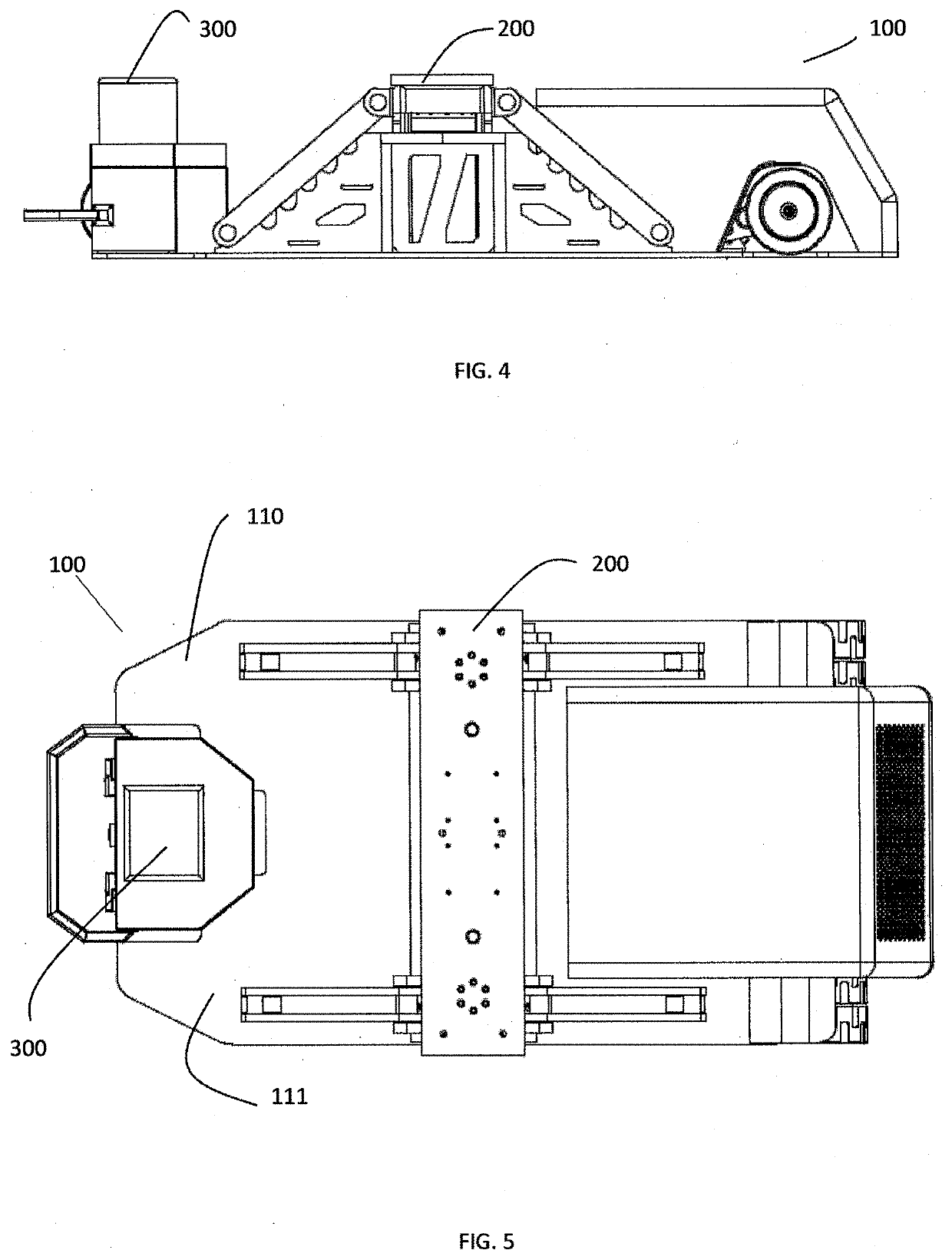

[0091]The jack 100 of the present application provides an integrated truck lifting solution. The jack 100 provides for reduced truck maintenance costs by reducing the time required to lift trucks for tire changing, repair, etc. In particular, according to one embodiment, the present application provides a jack 100 having a total collapsed height of approximately 33 inches with the ability to lift and extend linearly approximately 30 inches for a total working extend height of approximately 63 inches. This allows the jack 100 to fit under and lift a range of differently sized large capacity open pit mining haulage trucks 1000. In addition, the jack 100 has multiple visual secondary mechanical locking assemblies 810, 820, 830, 840 that ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com