Fog machine with continuous water supply

a technology of fog machine and water supply point, which is applied in the direction of liquid spraying apparatus, stage arrangements, theatre/circus, etc., can solve the problems of difficult to find the water supply point to successfully supply water, adversely affecting the fog generating effect, and inability to achieve continuous fog spray

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018]The embodiments of the invention will be further described in combination with the drawings.

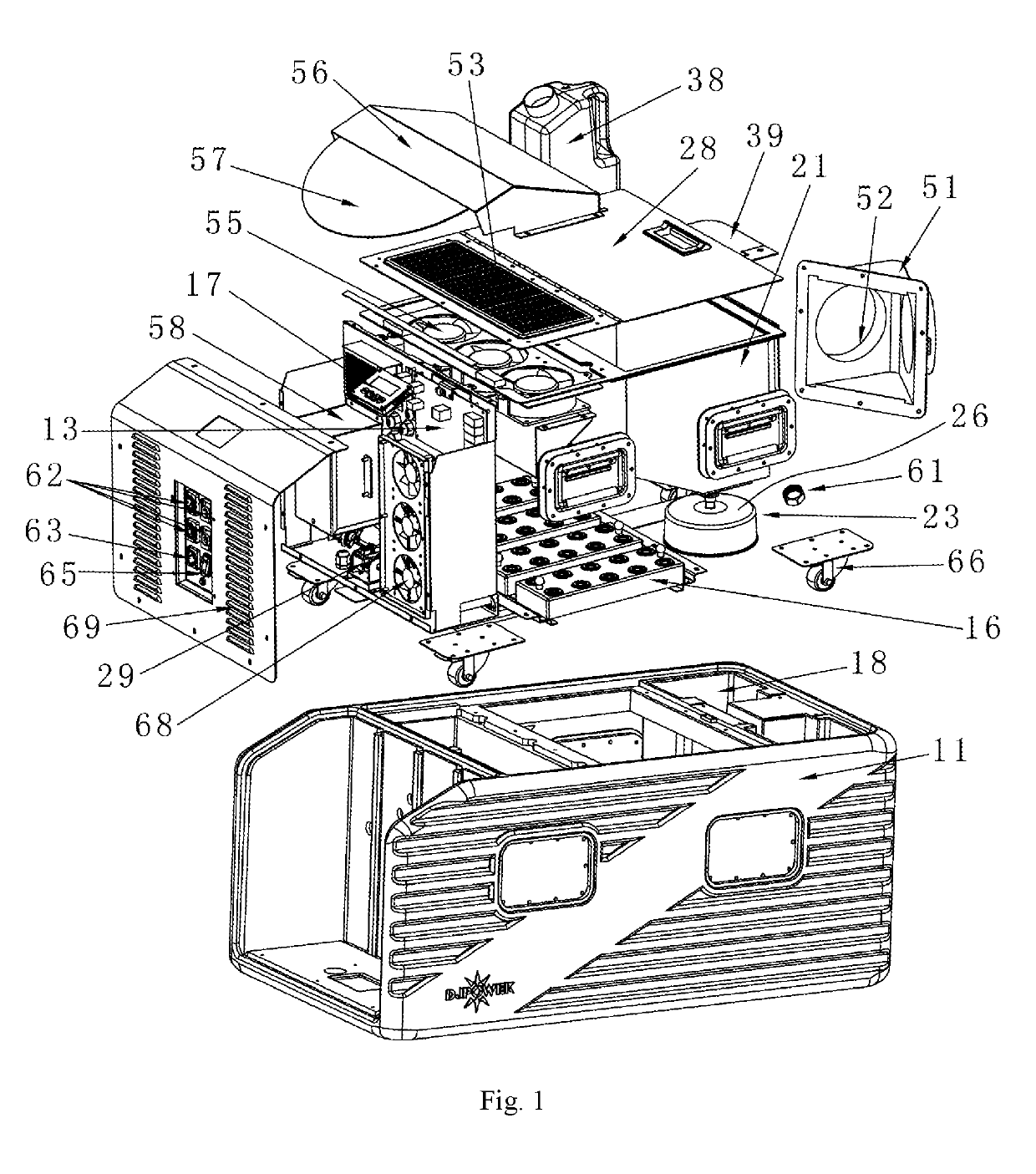

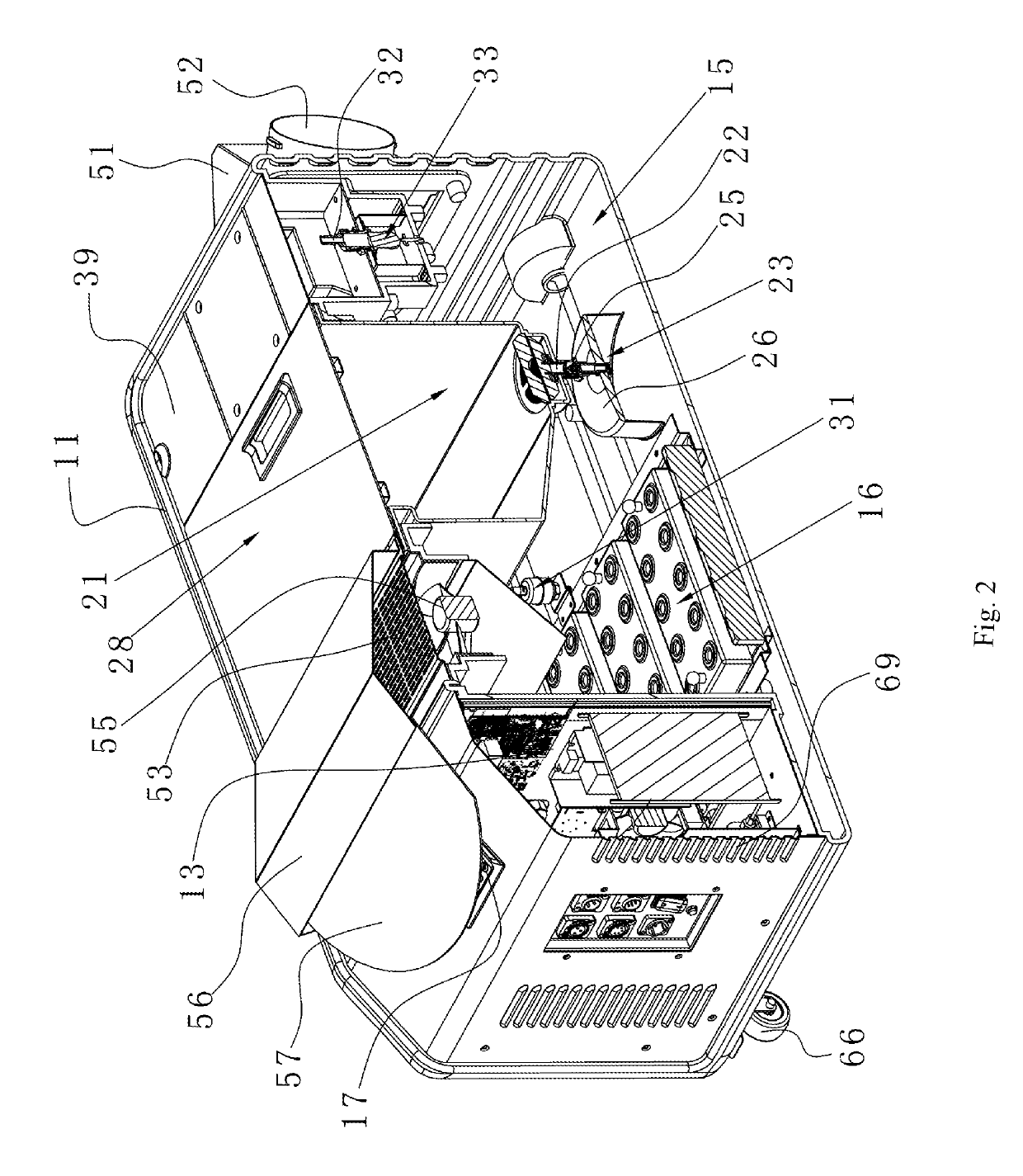

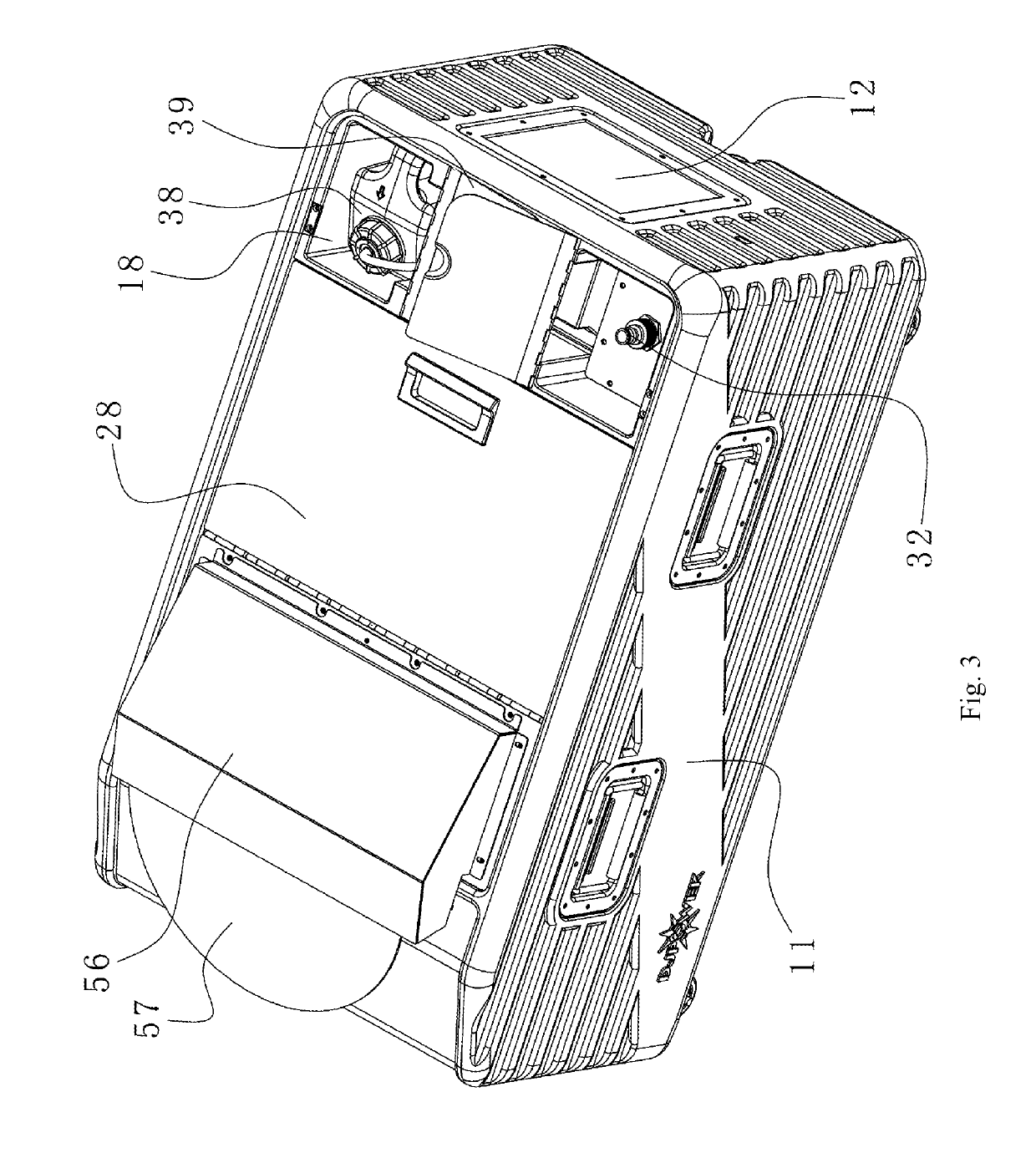

[0019]As shown in FIGS. 1, 2, and 3, the present invention provides a fog machine with continuous water supply, comprising: a main body 11 provided with a fog outlet 12, a circuit board 13 provided inside the main body, a water tank 15 provided at the bottom of the main body, a fog generator 16 provided in the water tank 15 and electrically connected with the circuit board 13, a water reservoir 21 provided above the water tank, a water filling port 22 provided at the bottom of the water reservoir 21, and a water filling switch 23 provided at the water filling port and controlled by the water level of the water tank, wherein the space above the water tank is in communication with the fog outlet 12. The water reservoir 21 is provided above the water tank 15 and the water filling switch 23 controls the water in the water reservoir 21 flowing into the water tank 15, wherein the opening and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com