A passive temperature control system for transport and storage containers

a temperature control system and container technology, applied in the field of transportation and storage of goods, can solve the problems of reducing the service life of the container, wasting resources, and wasting resources, and simplifying the loading process, so as to reduce waste and simplify the loading process. , the effect of simple solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment # 1

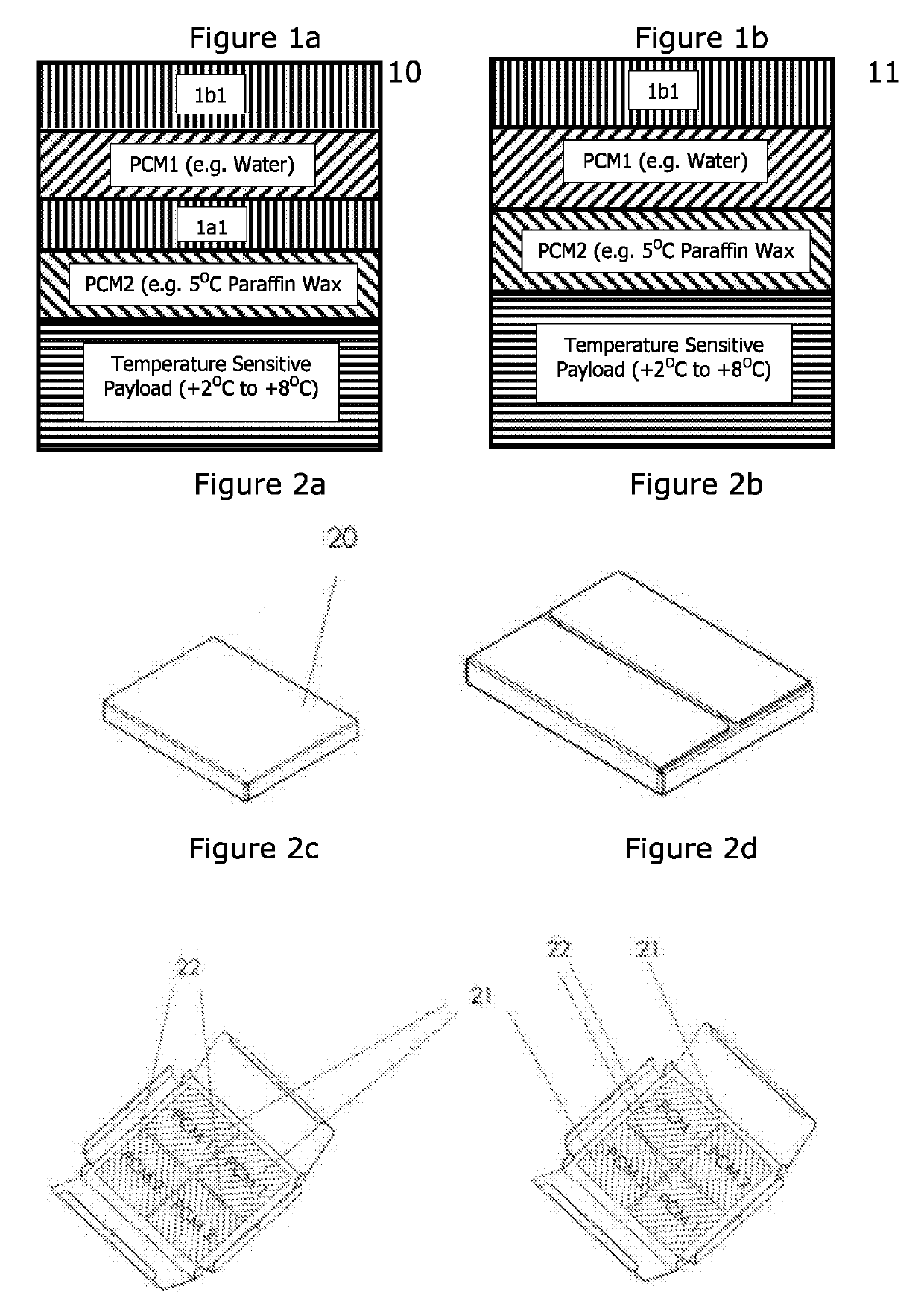

Embodiment #1—Adjacent—in Line

[0052]This embodiment has the two phase change materials in separate plastics bags in-line with each other, packed into the same cardboard container or cassette. It has been found that the provision of a layer of material having a high thermal conductivity in contact with the phase change materials plastics bags to allow a homogenous temperature to be created on the contact face (lowermost face) of the assembly—where it would contact the payload space in the temperature controlled package.

embodiment # 2

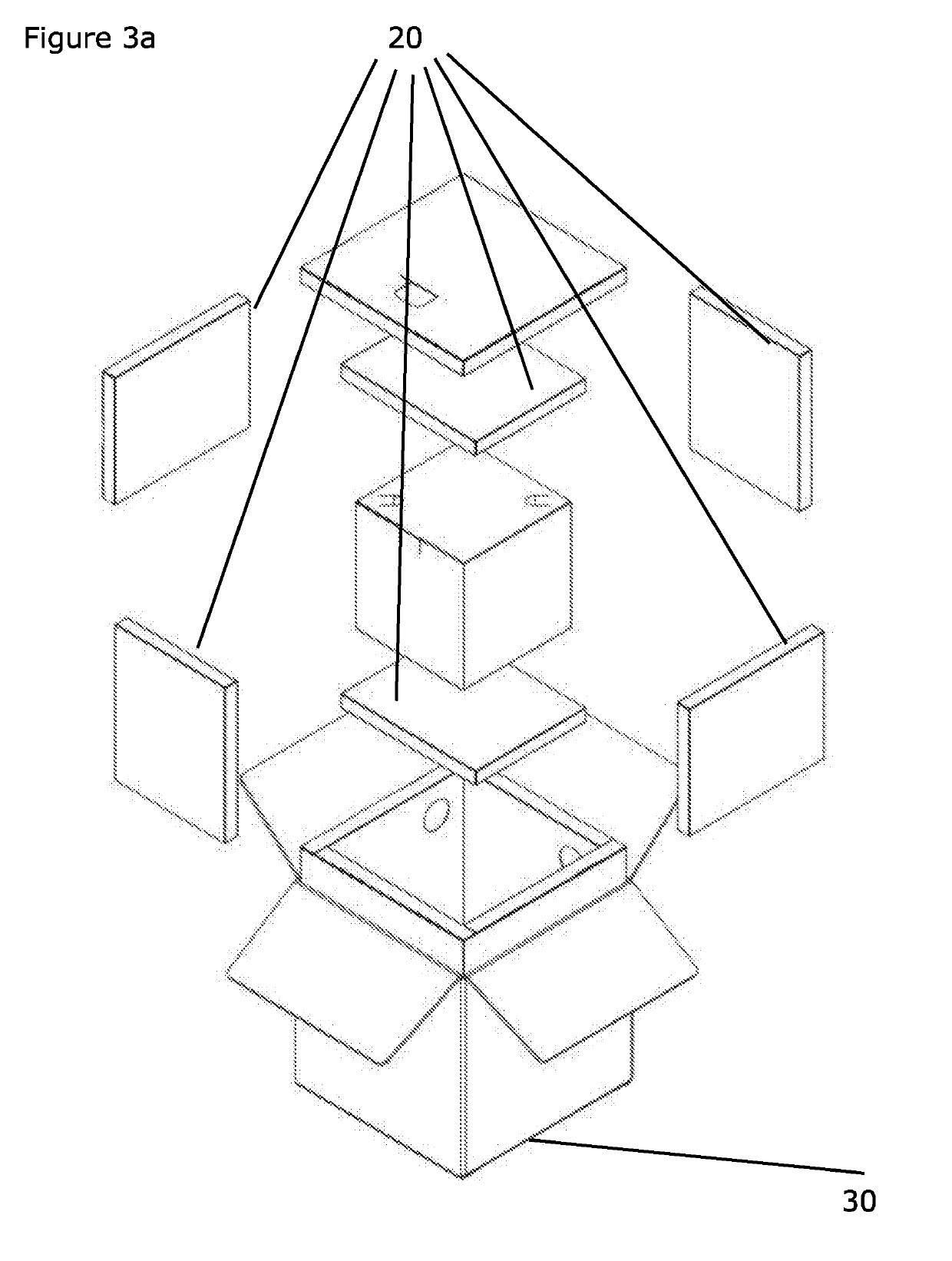

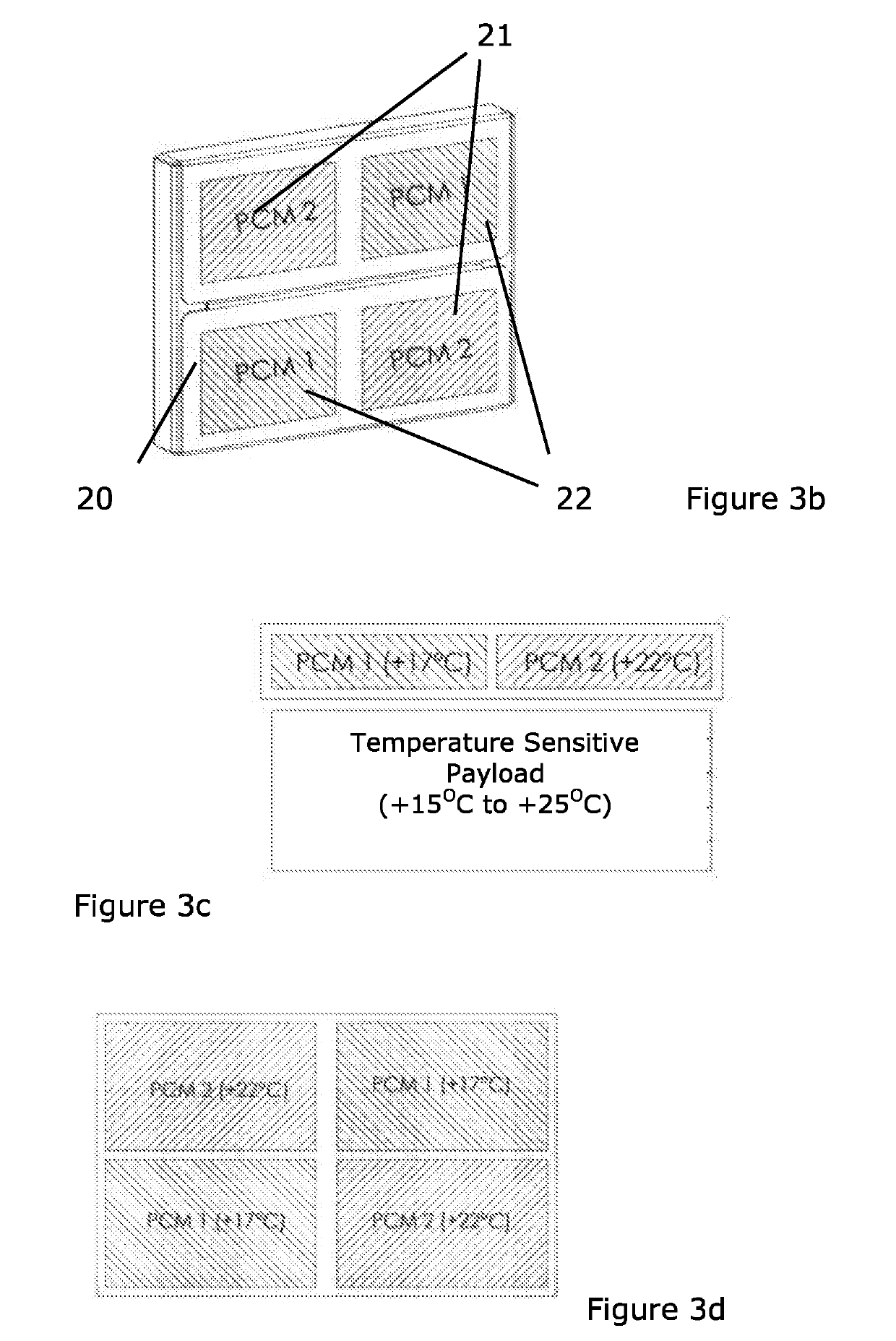

Embodiment #2—Adjacent—Alternating

[0053]This embodiment has the two phase change materials in separate plastics bags alternating with each other, packed into the cardboard container or cassette. This design is believed, in principle, to provide greater thermal stability than the first embodiment due to the better spread of the differing latent heat materials, but this might not be noticeable in practice. It has been found that the provision of a layer of material having a high thermal conductivity in contact with the phase change materials plastics bags to allow a homogenous temperature to be created on the contact face (lowermost face) of the assembly—where it would contact the payload space in the temperature controlled package.

[0054]To enable a simple appraisal of the thermal capability of the present invention, extensive thermal testing has been performed, with reference the results of which show a distinct advantage of the Dual Adjacent PCM system of a system with only one or t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com