Vent for exhaust system

a technology for exhaust systems and vents, applied in space heating and ventilation details, lighting and heating apparatuses, heating types, etc., can solve problems such as motor vibration, exhaust system performance grey area, exhaust system noisy, etc., and achieve the effect of reducing the ingress of foreign objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

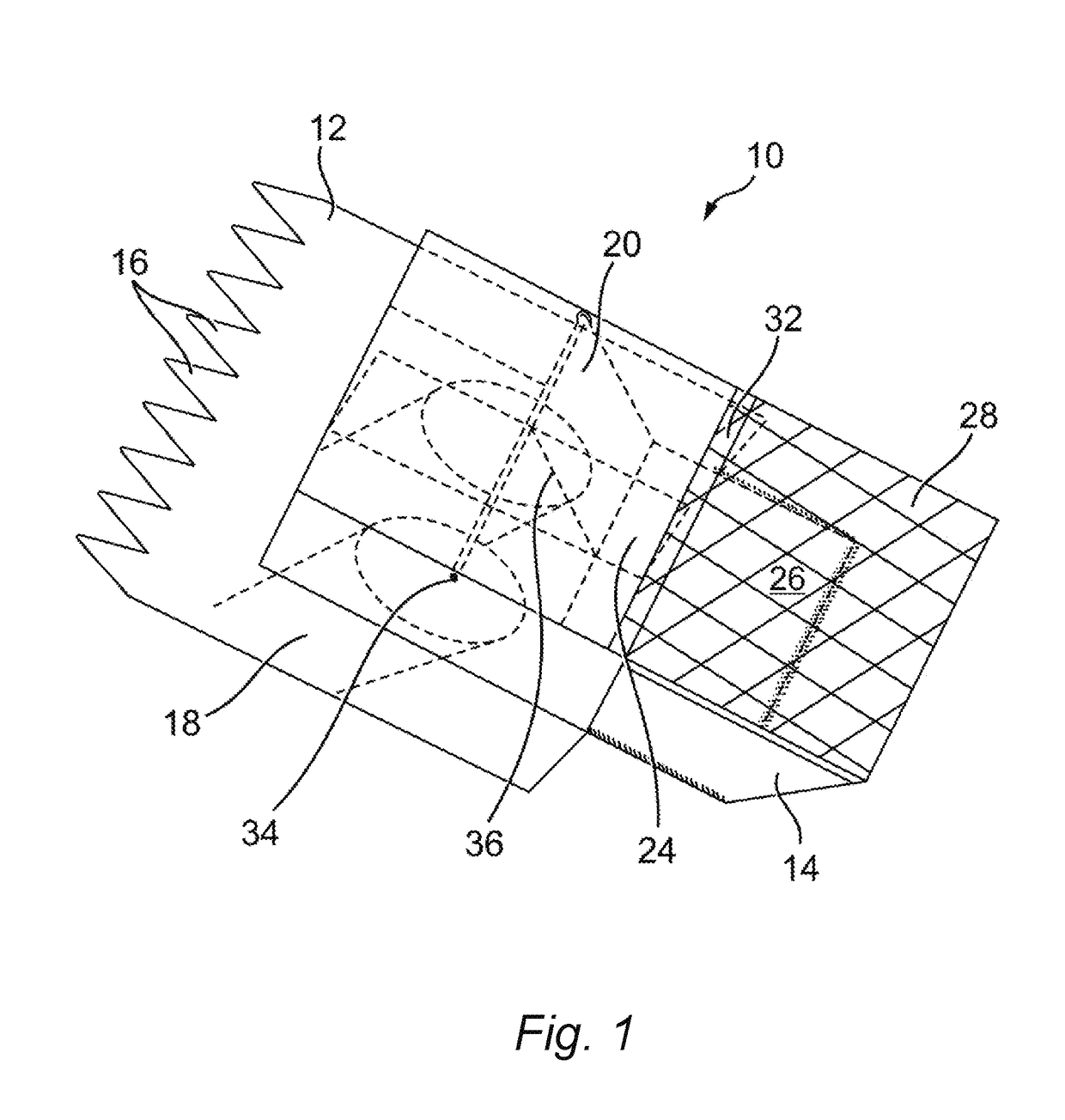

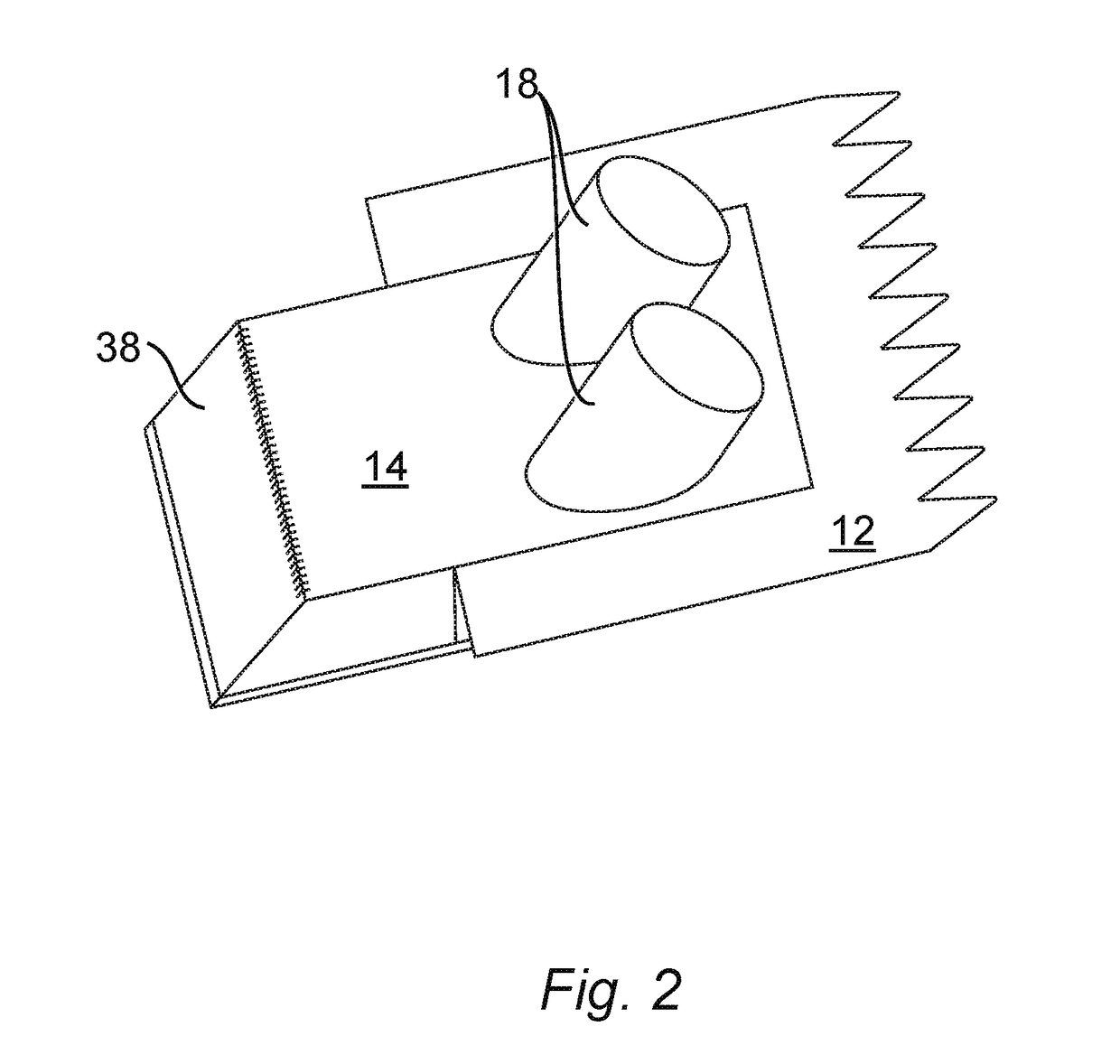

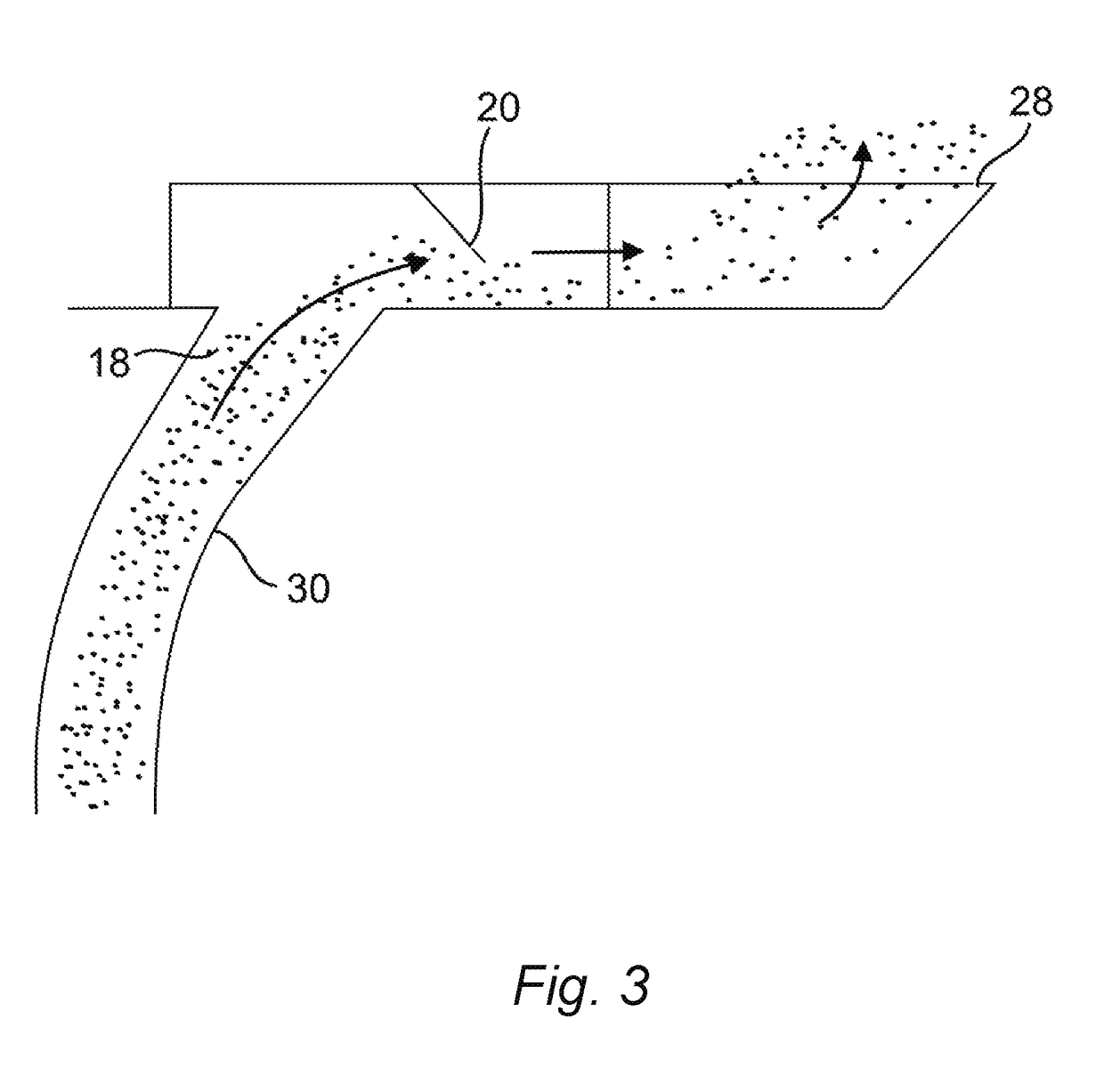

[0030]Referring to the Figures, there is shown an apparatus for improved roof venting for exhaust, generally indicated by reference numeral 10. As best seen in FIG. 1, the exhaust roof vent 10 comprises a shroud 12 and box 14 forming a shell of the vent 10. It is preferred that the shroud 12 and box 14 are constructed from COLORBOND® steel to complement steel-roofed buildings, for example, and from 0.55 mm galvanised tin to complement tiled roofs or walls of other materials upon which the vent 10 is mounted. Each of the shroud 12 and box 14 are preferably formed of a solitary piece punched from sheet material, then folded and fixed into its finished shape.

[0031]The shroud 12 comprises fingers 16 in an end distal from the box 14 when the vent 10 is assembled. The fingers 16 complement the corrugations in COLORBOND® steel so as to provide a snug connection between the shroud and the roof for adequate weather proofing.

[0032]In the case of mounting on material other than COLORBOND® stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com