Snow shaving auger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

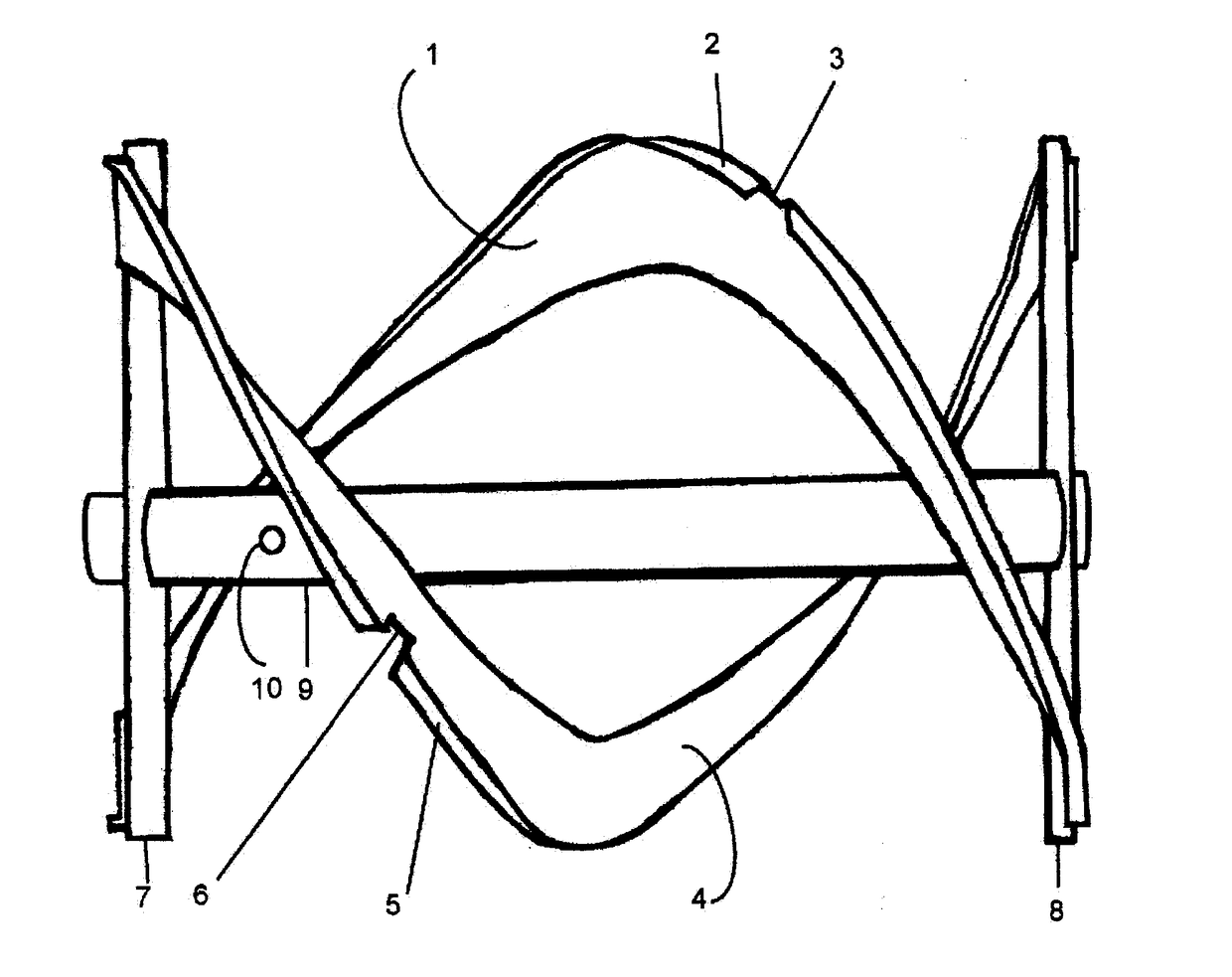

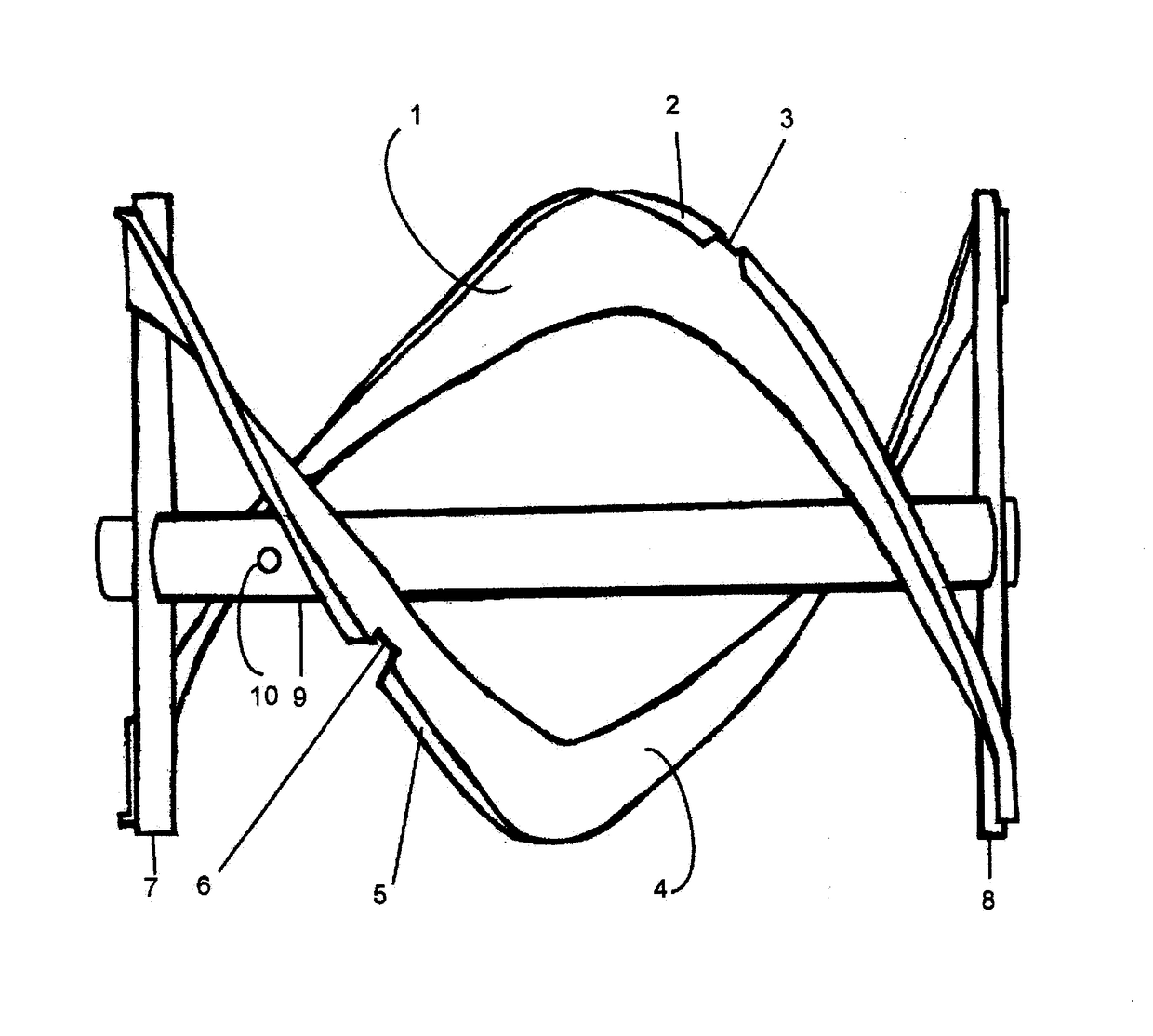

[0014]The accompanying description and drawing should in no way be considered the only formation of the snow blower auger possible but the inventor's primary example. All parts of the invention are of strong and durable material made for all weather use without breaking.

[0015]The elements of the invention in the drawing depict the main auger double helix (1 and 4), the periphery of the helixes being continuously bent parallel with their axis and outermost edges and at an angle in the direction of helical progression (2 and 5), nips being removed from the helical periphery to facilitate beginning a new slice into hard packed snow (3 and 6), flanked by and affixed to two reinforced flat bars (7 and 8) at each end of the double helix which are skewered through the center and affixed to by an auger axle pipe (9) through which an open ended hole (10) is put to facilitate placing a shear bolt through said auger axle pipe (9).

[0016]The auger axle pipe (9) should be long enough to just fit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com