Multi-caliber dimensional inspection device for an assembled cartridge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

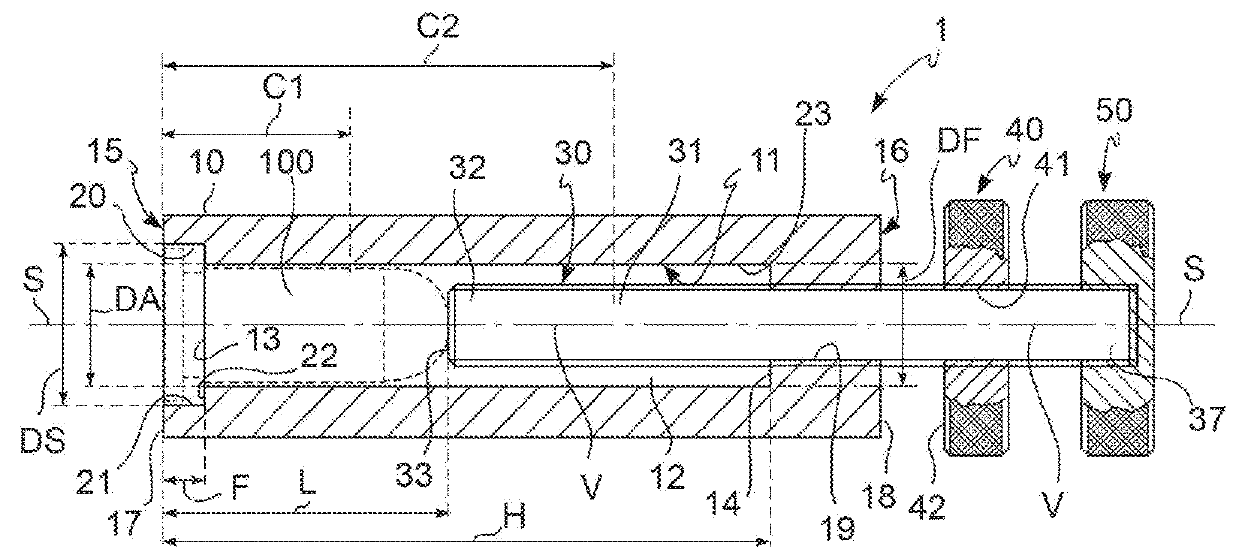

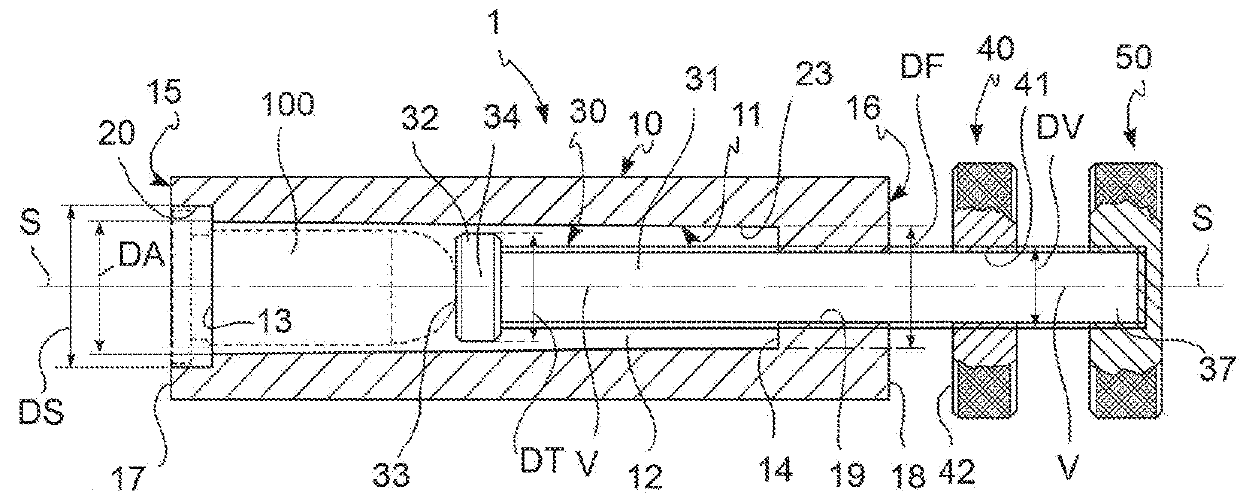

[0033]With reference to the figures, a dimensional inspection device for inspecting the dimensions of a recharged cartridge, or the overall length of a recharged cartridge, is shown by reference numeral 1 as a whole.

[0034]The dimensional inspection device 1 comprises a measuring body 10 defining a first free body end 15 and a second opposite free body end 16.

[0035]The first free body end 15 comprises a first reference surface 17, and the second free end 16 comprises a locking surface 18.

[0036]The measuring body 10 further comprises a cavity 11 for housing a cartridge, which extends into the measuring body 10 of the aforesaid reference surface 17 towards the second free end 16.

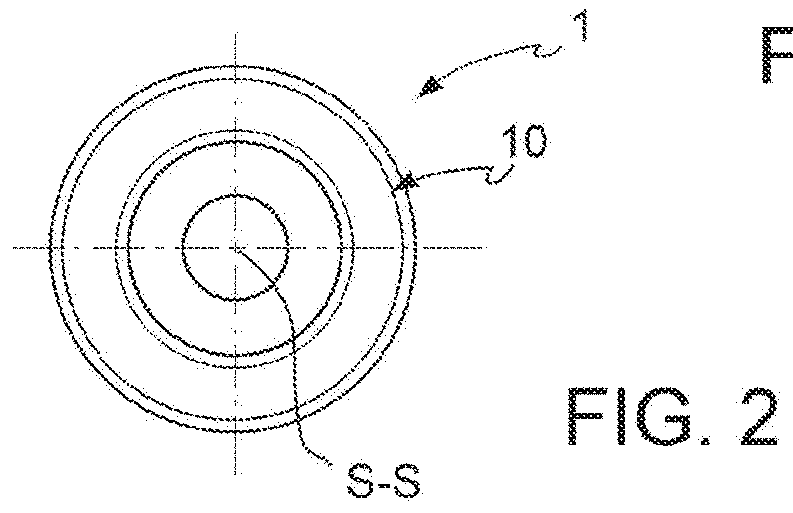

[0037]The cavity 11 for housing a cartridge comprises a hole 12 for receiving a cartridge defining a hole axis S-S, a hole end opening 13 facing towards the first reference surface, and a hole end bottom 14 opposite to the hole end opening 13.

[0038]The measuring body 10 further comprises a threaded through hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com