Ammunition projectile having improved aerodynamic profile and method for manufacturing same

a technology of aerodynamic profile and ammunition projectile, which is applied in the field of ammunition projectiles, can solve the problems of adversely affecting and achieve the effect of improving the aerodynamic efficiency of the projectil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

.

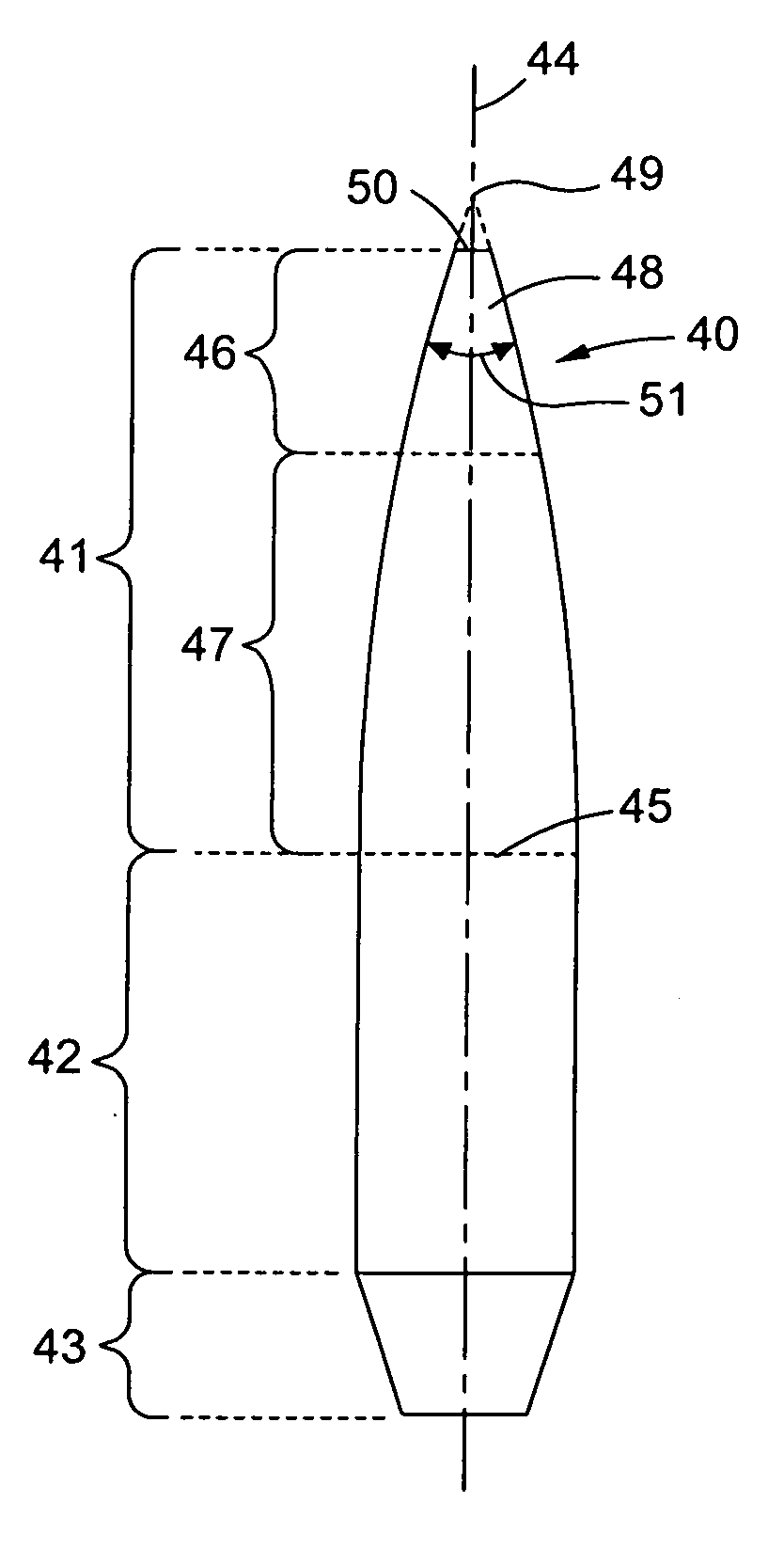

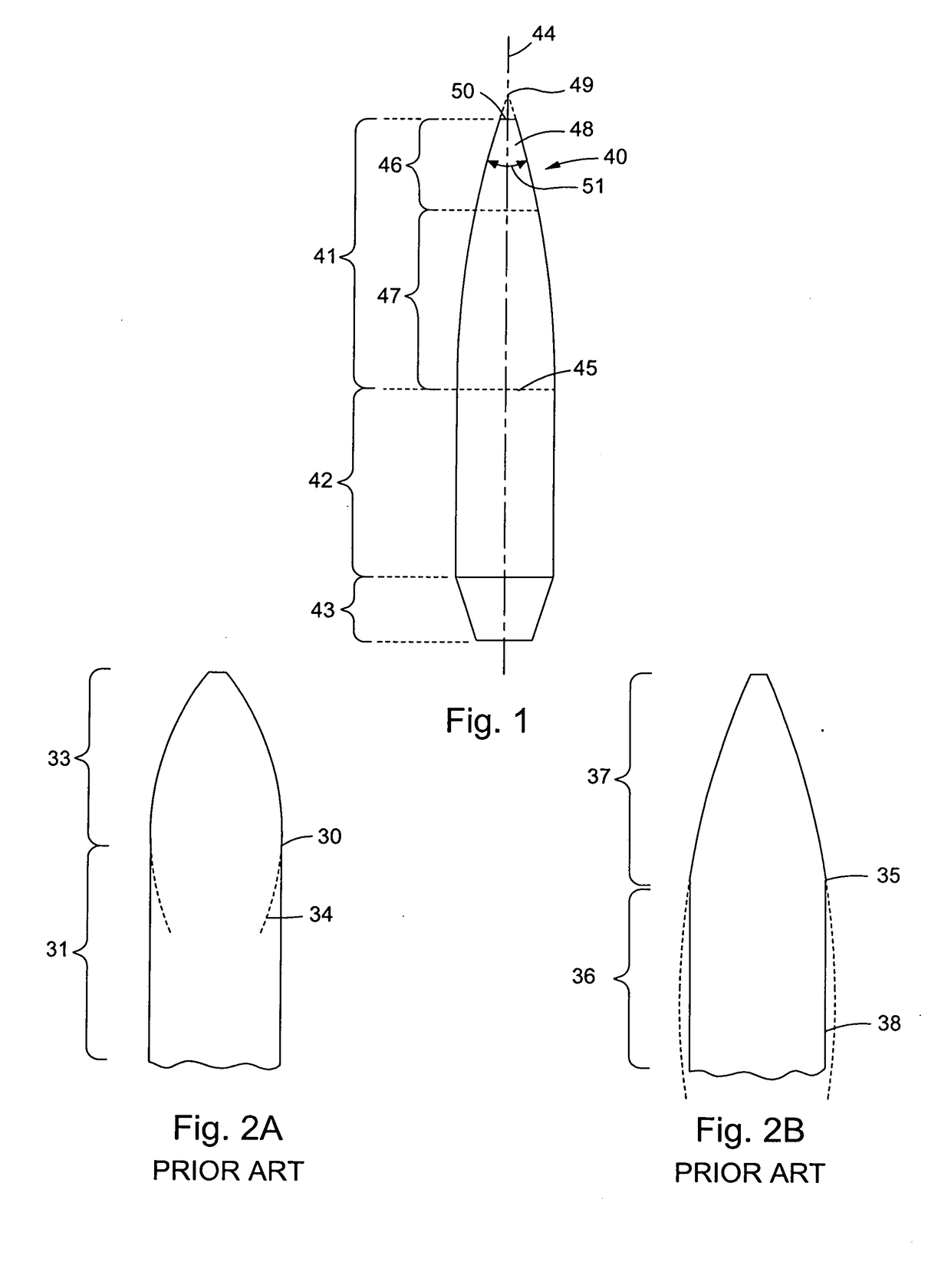

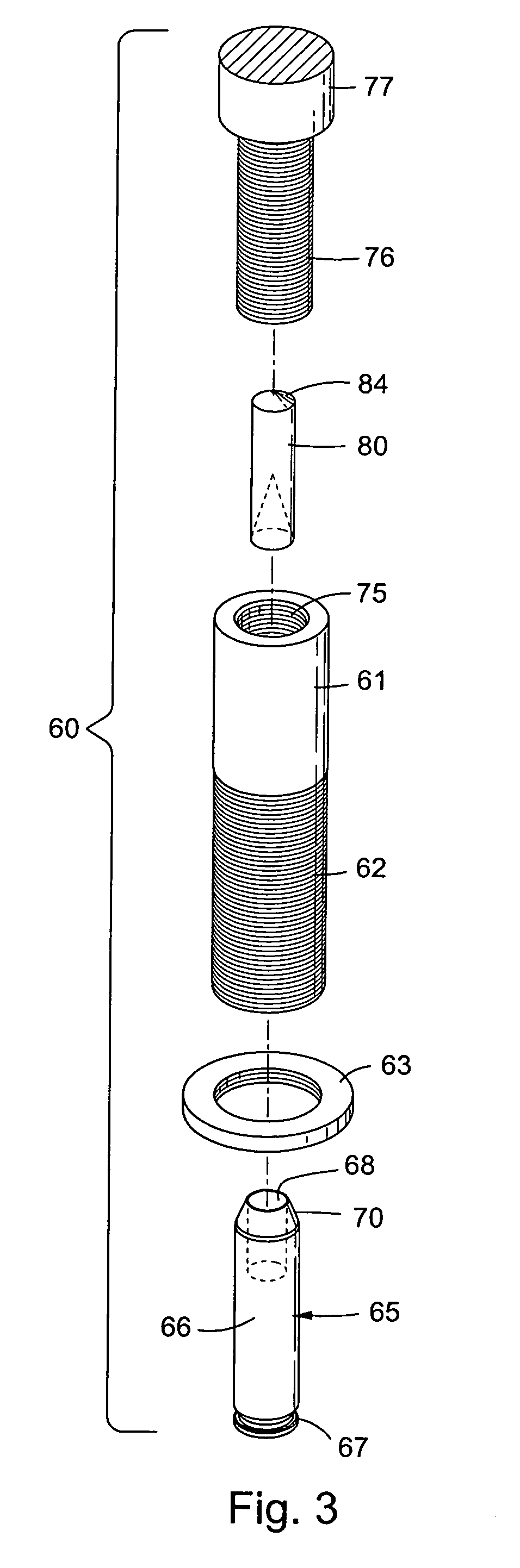

[0021]The present invention design for the improvement of a projectile for a firearm can be best understood by initial reference to FIGS. 2a and 2b which illustrate prior art projectile designs employing a tangent ogive design and a secant ogive design, respectively. The design of a bullet or projectile for firearms must solve two basic problems. Firstly, while the projectile is in the barrel of a firearm, it must form a seal with the firearm's bore. The projectile must also engage the barrel rifling without damaging or excessively fouling the firearms bore, and, without distorting the projectile which could reduce accuracy. The interactions between the projectile and the bore of the firearm is generally referred to as “internal ballistics.” The present invention relates to the principles affecting the projectile once it leaves the barrel of the firearm, this being generally referred to as “external ballistics.” The geometry of a bullet or projectile can be broken down into symmetr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com