Carbazole Derivative, and Light-Emitting Element, Light-Emitting Device, and Electronic Device Using the Carbazole Derivative

a technology of carbazole and derivative, which is applied in the direction of luminescent compositions, organic chemistry, chemistry apparatus and processes, etc., can solve the problems of lowering the luminous efficiency of the light-emitting element and the difficulty of obtaining this characteristic, and achieves low power, high luminous efficiency, and low voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment mode 1

[0088]In Embodiment Mode 1, a carbazole derivative of the present invention will be described.

[0089]The carbazole derivative of the present invention is represented by a general formula (1).

[0090]In the formula, α1, α2, α3, and α4 each represent an arylene group having less than or equal to 13 carbon atoms, which forms a ring; Ar1 and Ar2 each represent an aryl group having less than or equal to 13 carbon atoms, which forms a ring; R1 represents any of a hydrogen atom, an alkyl group having 1 to 6 carbon atoms, a substituted or unsubstituted phenyl group, and a substituted or unsubstituted biphenyl group; and R2 represents any of alkyl group having 1 to 6 carbon atoms, a substituted or unsubstituted phenyl group, and a substituted or unsubstituted biphenyl group. In addition, l, m, and n are each independent, which is 0 or 1.

[0091]In the general formula (1), α1 to α4 each represent an arylene group having less than or equal to 13 carbon atoms, which forms a ring. Specifically, subst...

embodiment mode 2

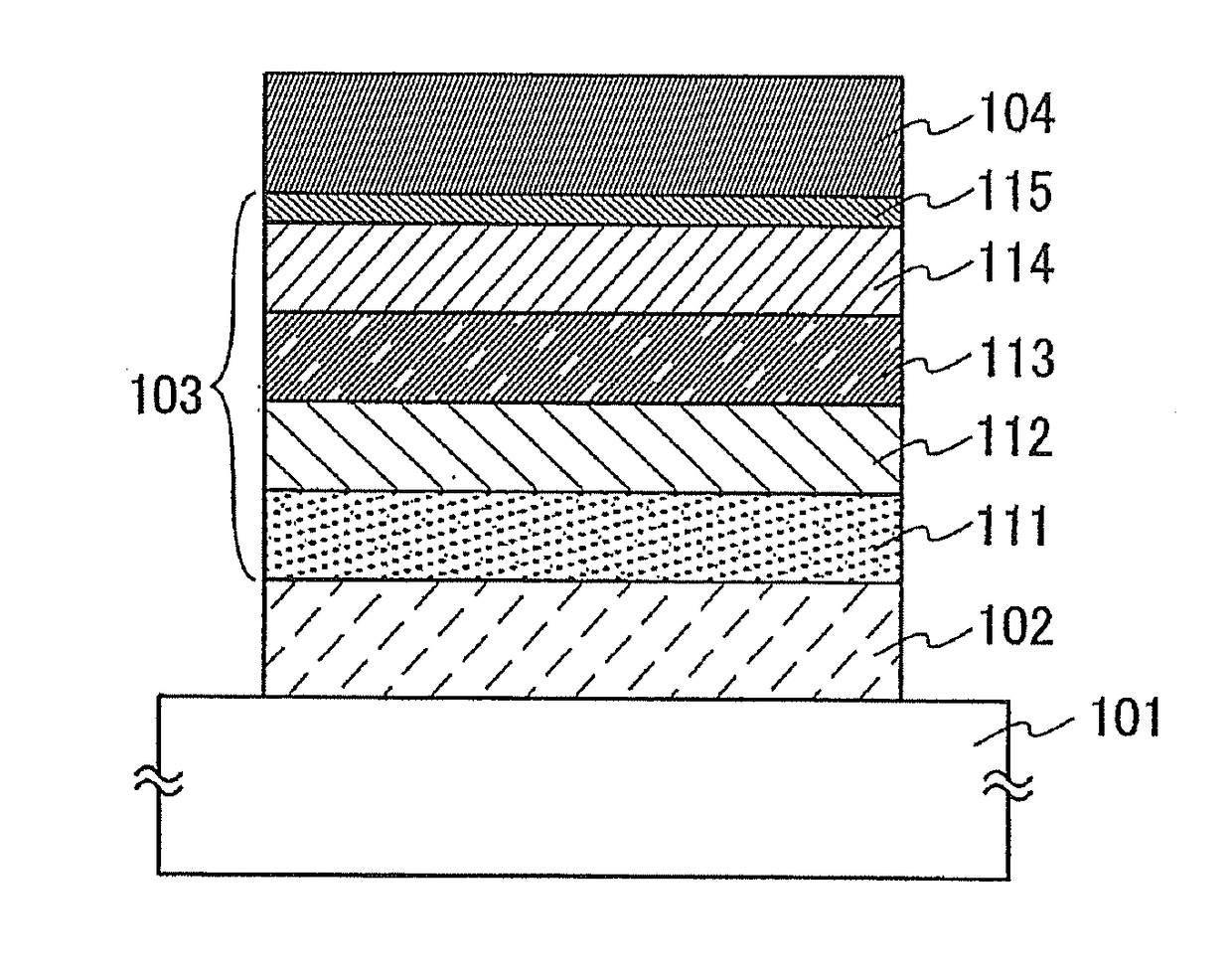

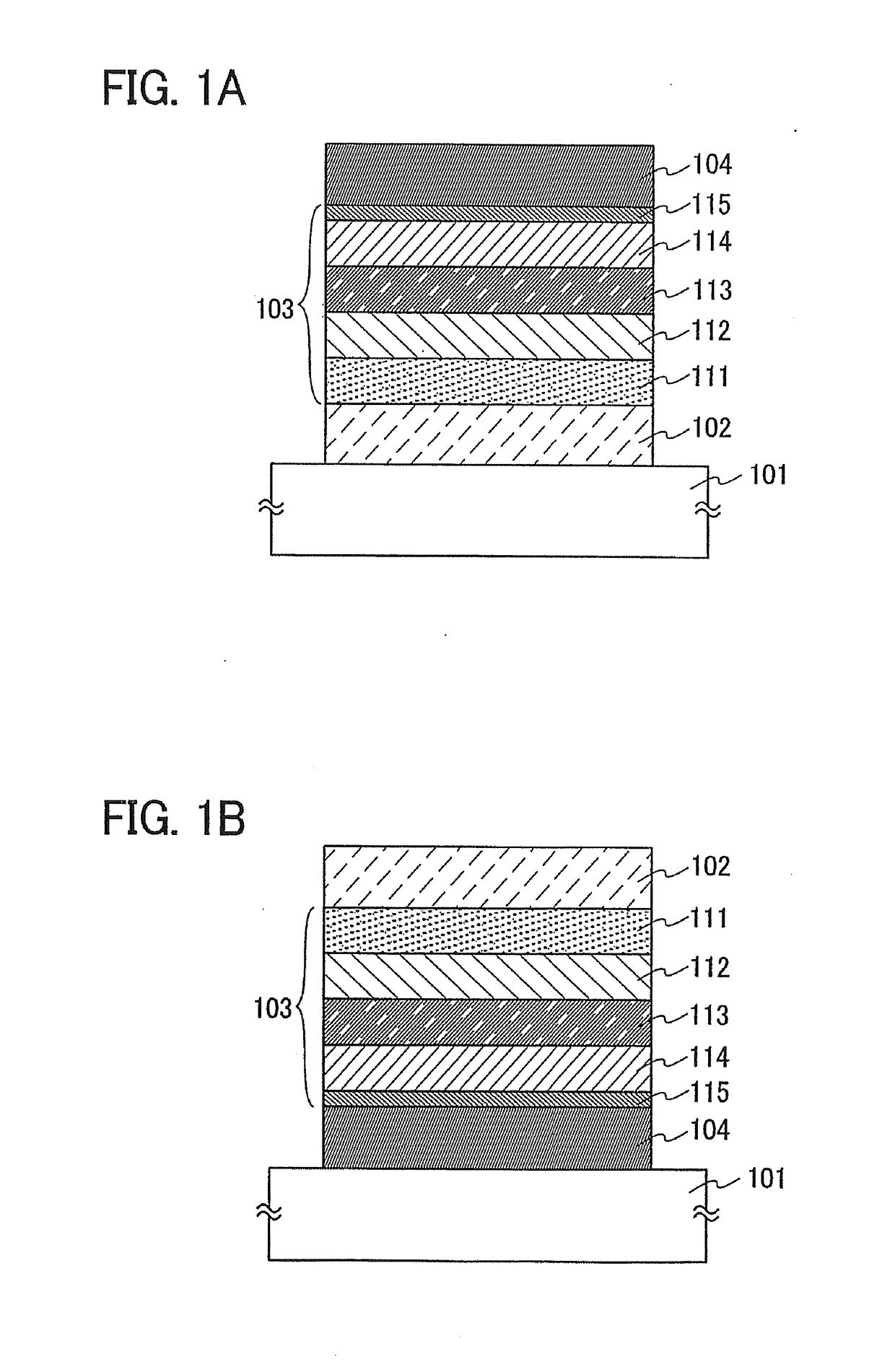

[0128]In Embodiment Mode 2, a light-emitting element which is formed using, for a hole-transporting layer, the carbazole derivative of the present invention described in Embodiment Mode 1 will be described.

[0129]The light-emitting element in Embodiment Mode 2 includes a first electrode which functions as an anode, a second electrode which functions as a cathode, and an EL layer interposed between the first electrode and the second electrode. Note that the light-emitting element in Embodiment Mode 2 can obtain light emission when voltage is applied to each electrode so that the potential of the first electrode is higher than that of the second electrode.

[0130]In addition, the EL layer of the light-emitting element in Embodiment Mode 2 includes in its structure a first layer (a hole-injecting layer), a second layer (a hole-transporting layer), a third layer (a light-emitting layer), a fourth layer (an electron-transporting layer), and a fifth layer (an electron-injecting layer), from ...

embodiment mode 3

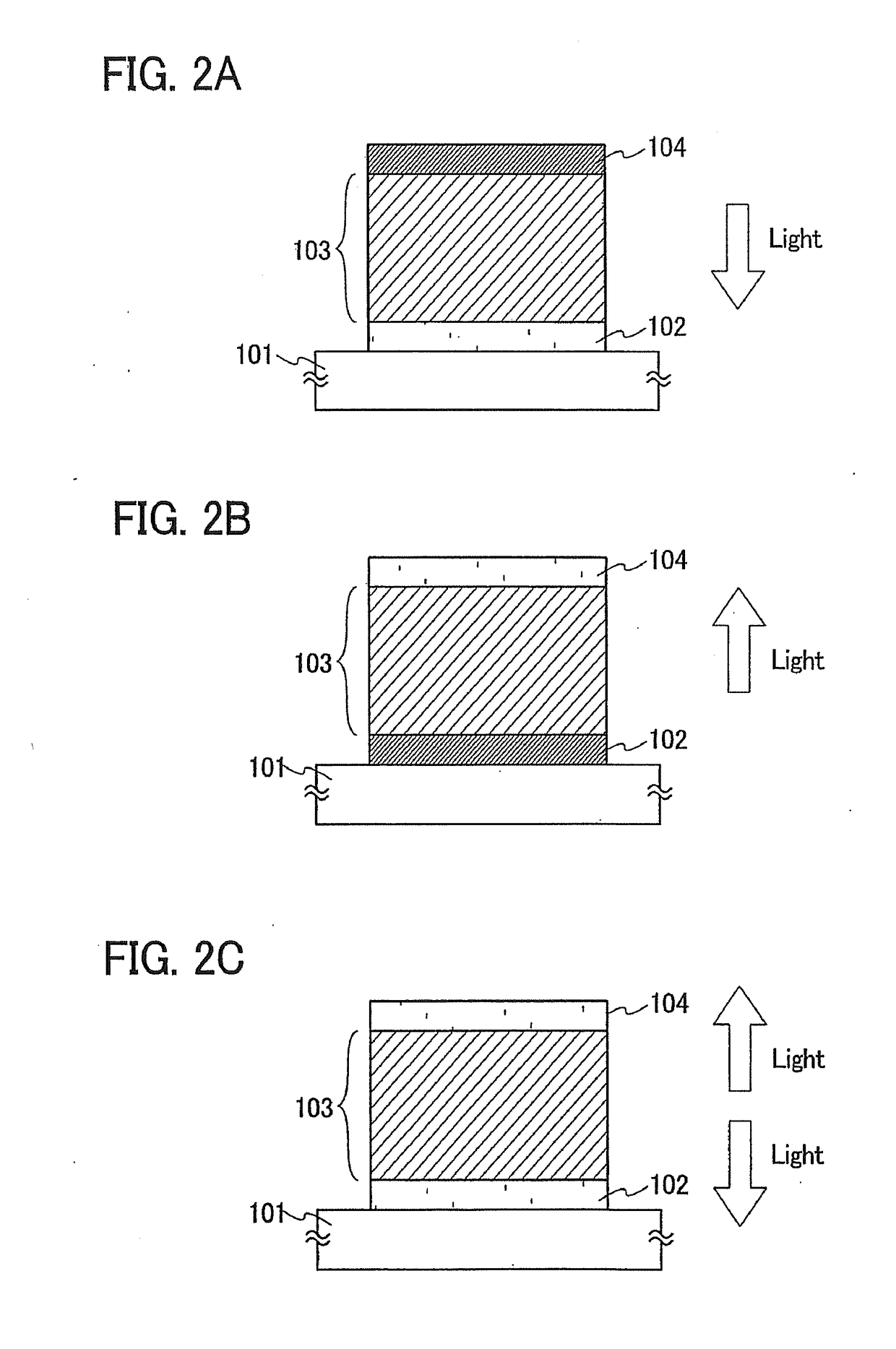

[0183]In Embodiment Mode 3, a light-emitting element having a plurality of EL layers any of the light-emitting elements described in Embodiment Mode 2 (hereinafter referred to as a stacked-type light-emitting element) will be described with reference to FIG. 3. This light-emitting element is a stacked-type light-emitting element that has a plurality of EL layers (a first EL layer 303 and a second EL layer 304) between a first electrode 301 and a second electrode 302. Note that although a structure of two EL layers is described in Embodiment Mode 3, a structure of three or more EL layers may also be employed.

[0184]In Embodiment Mode 3, the first electrode 301 functions as an anode, and the second electrode 302 functions as a cathode. Note that for the first electrode 301 and the second electrode 302, structures similar to those described in Embodiment Mode 1 can be employed. Further, for the plurality of EL layers (the first EL layer 303 and the second EL layer 304), structures simil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| work function | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com