Flexible printed circuit board

a printed circuit board and flexible technology, applied in the direction of printed circuit assembling, printed circuit manufacturing, printed circuit aspects, etc., can solve the problem that air in the through holes cannot escape, and achieve the effect of sufficient strength and satisfactory conductivity for a long tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

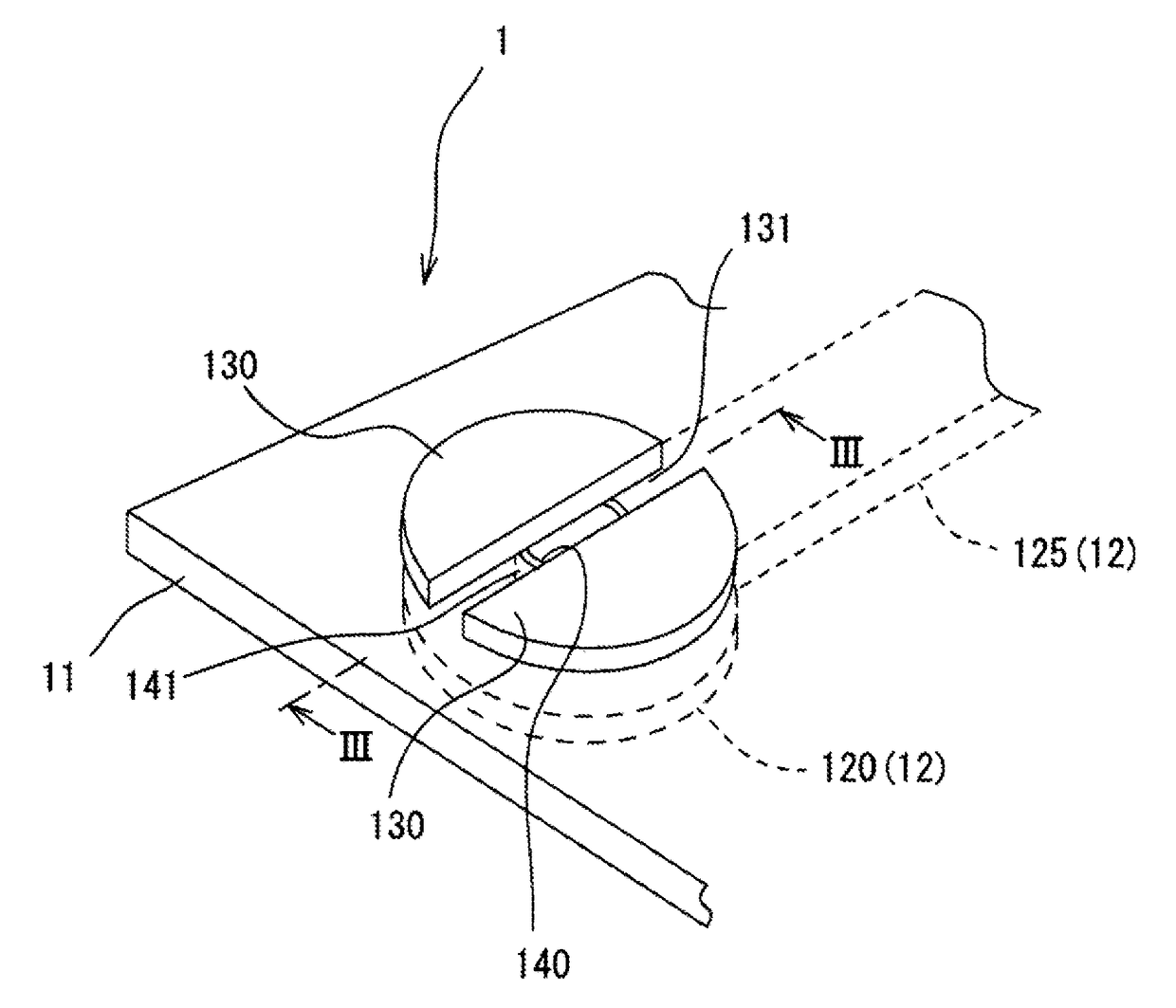

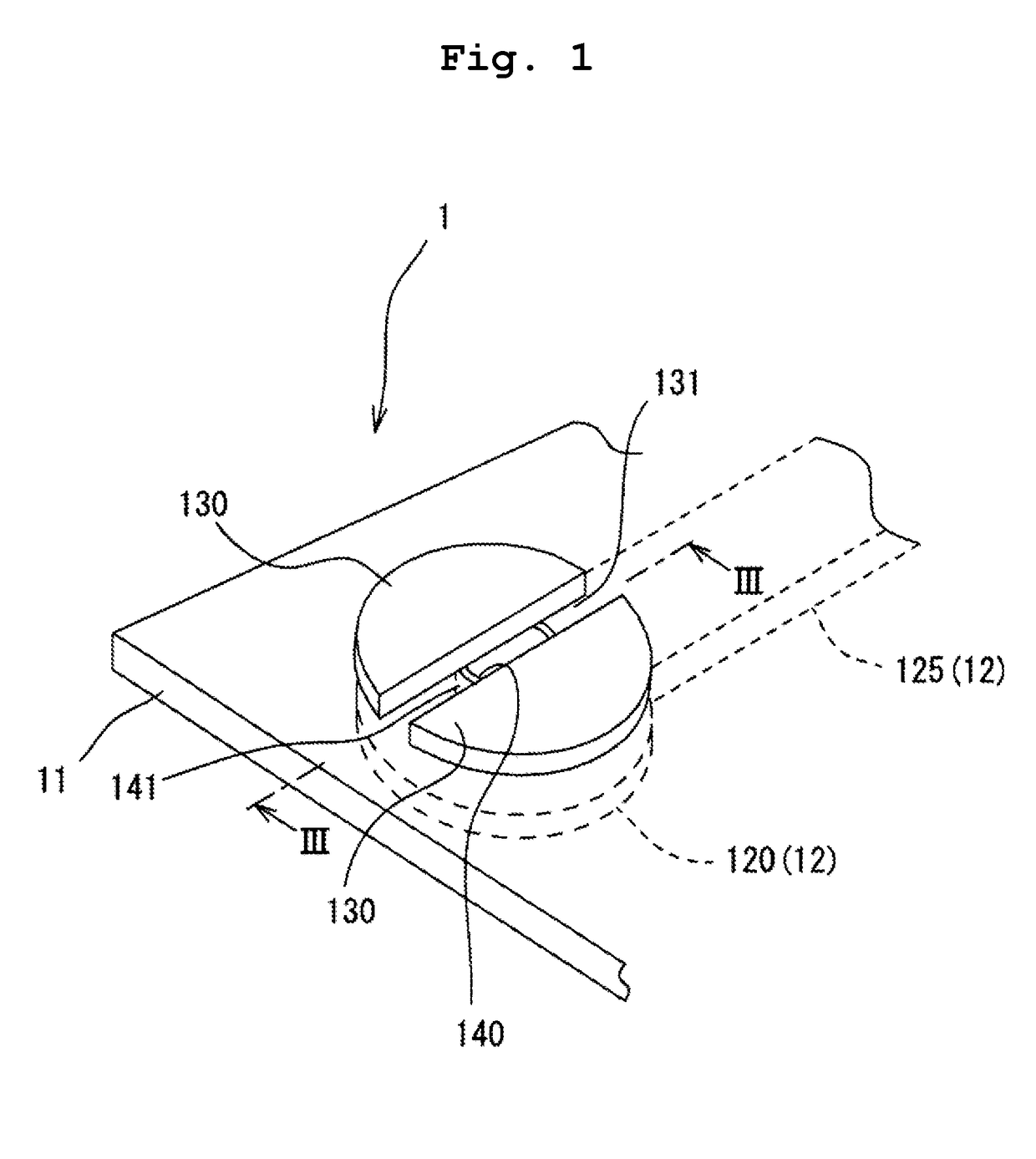

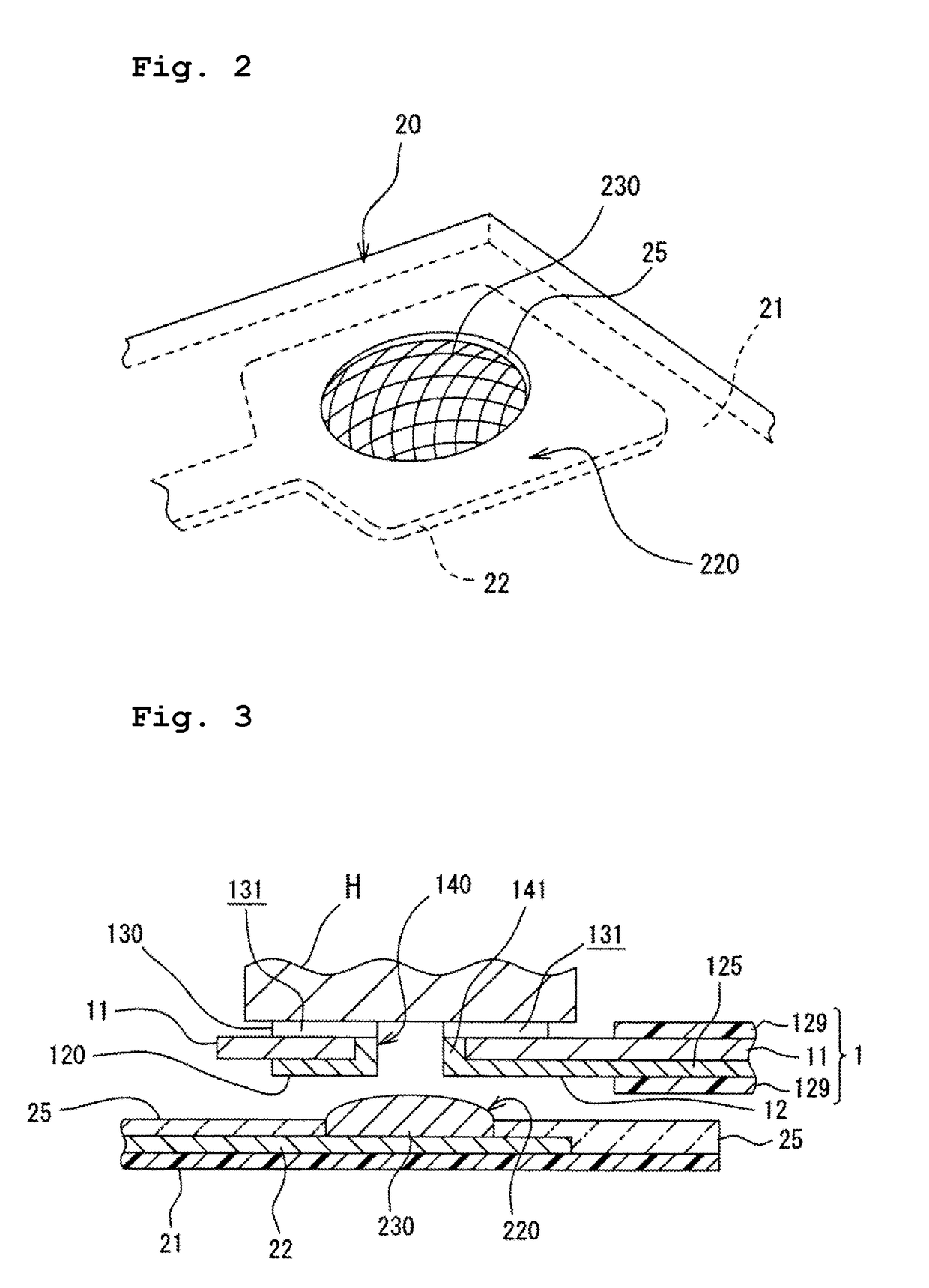

[0017]In the following, an explanation will be made with reference to the drawings about a flexible printed circuit board 1 related to an embodiment of the present teaching. FIG. 1 is a perspective view of the flexible printed circuit board 1 related to the embodiment of the present teaching as viewed from the side of one of lands (heating side land 130) of an electrode provided in the flexible printed circuit board 1. FIG. 2 is a perspective view depicting a counterpart electrode to be connected to the flexible printed circuit board 1 depicted in FIG. 1 with soldering. FIGS. 3 and 4 are illustrative views chronologically illustrating states that the flexible printed circuit board 1 related to this embodiment is crimped or pressure welded to a part of another flexible printed circuit board having the counterpart electrode through thermocompression bonding.

[0018]In the drawings, the sizes, thicknesses, and dimensions of components or parts related to the embodiment and modified embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com