Porous Sintered Superstructure with Interstitial Silicon for Use in Anodes for Lithium Batteries

a lithium battery, interstitial silicon technology, applied in the field of batteries, can solve problems such as sacrifice of some capacity, and achieve the effect of high lithiation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

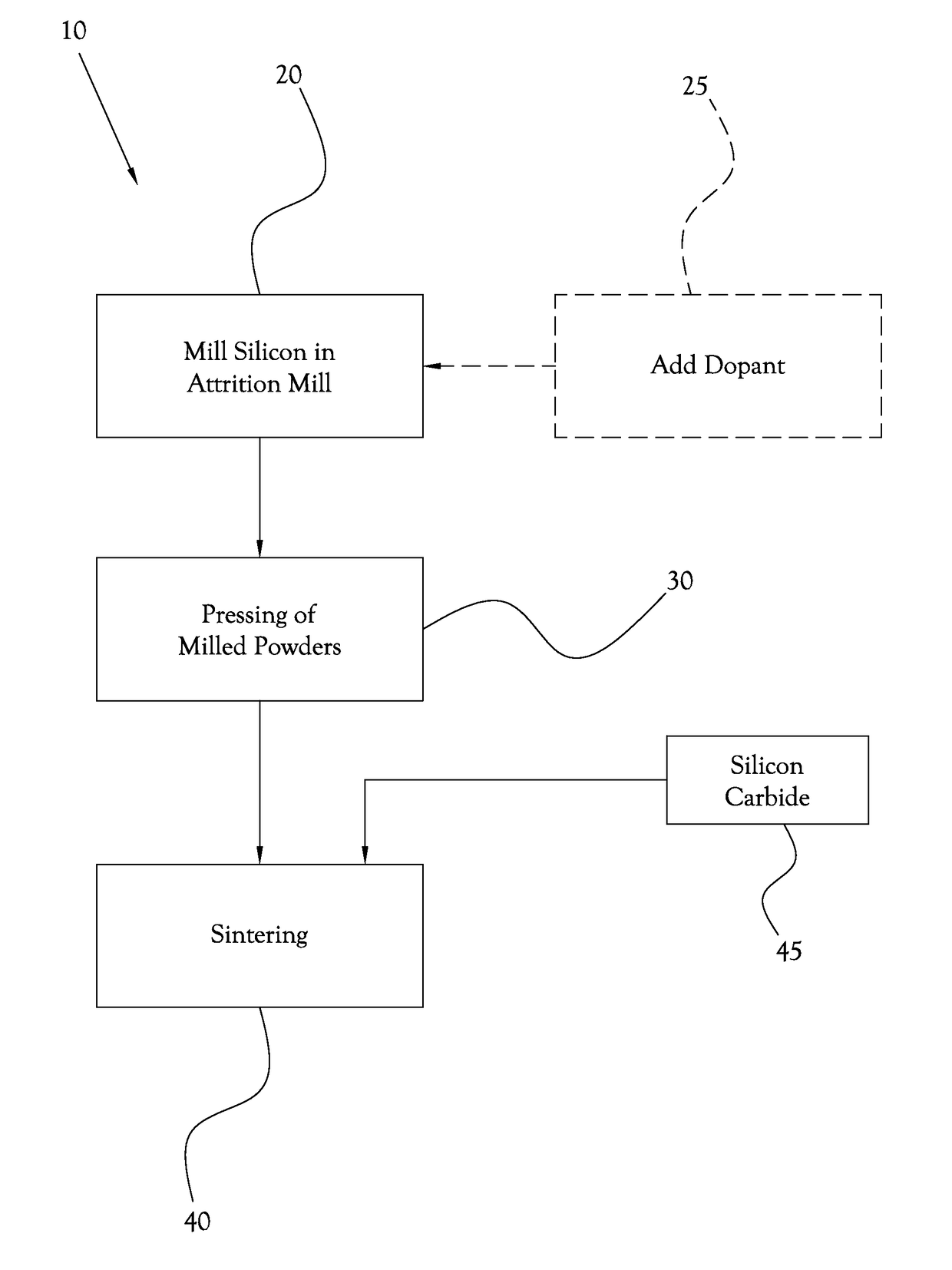

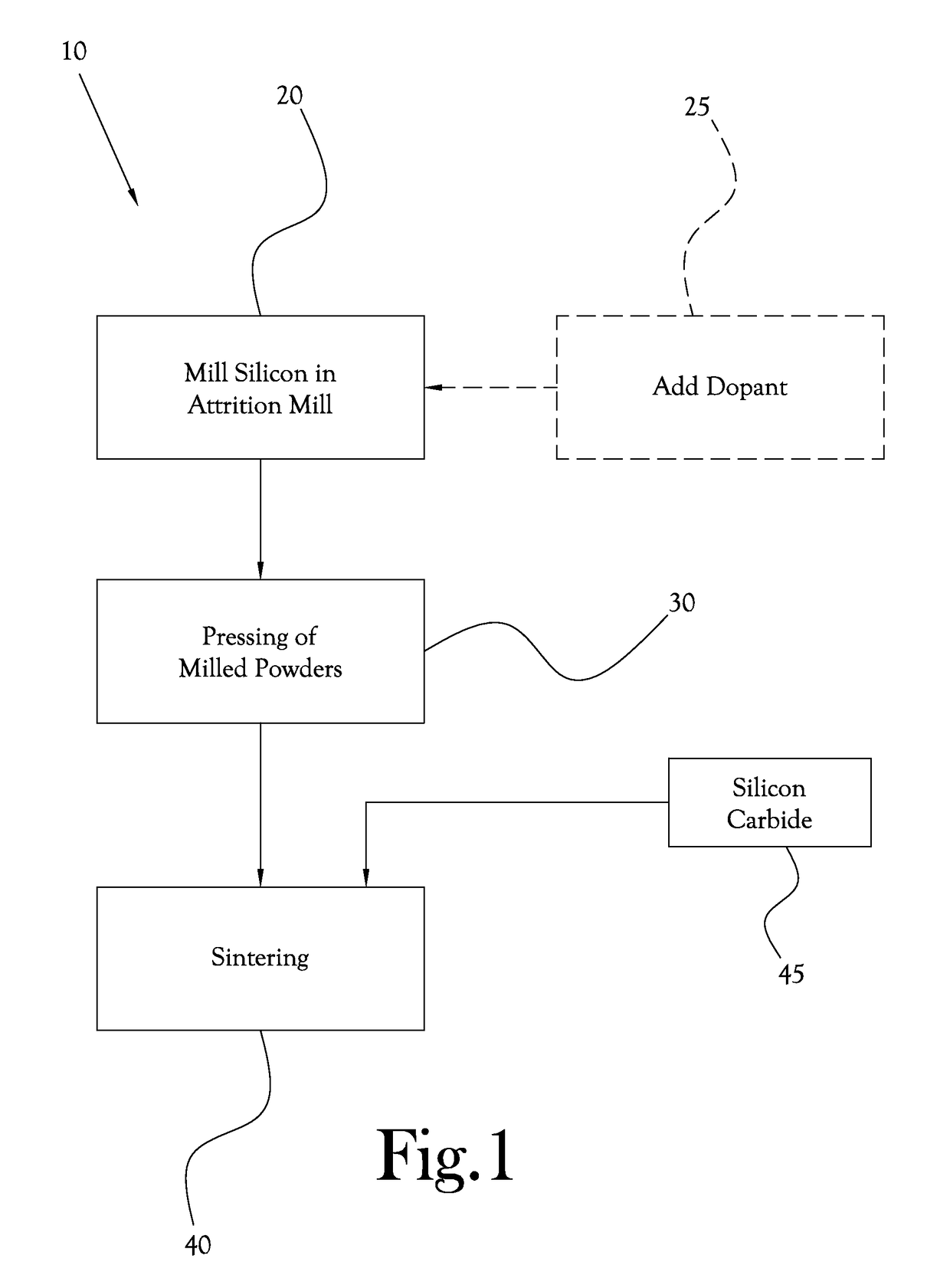

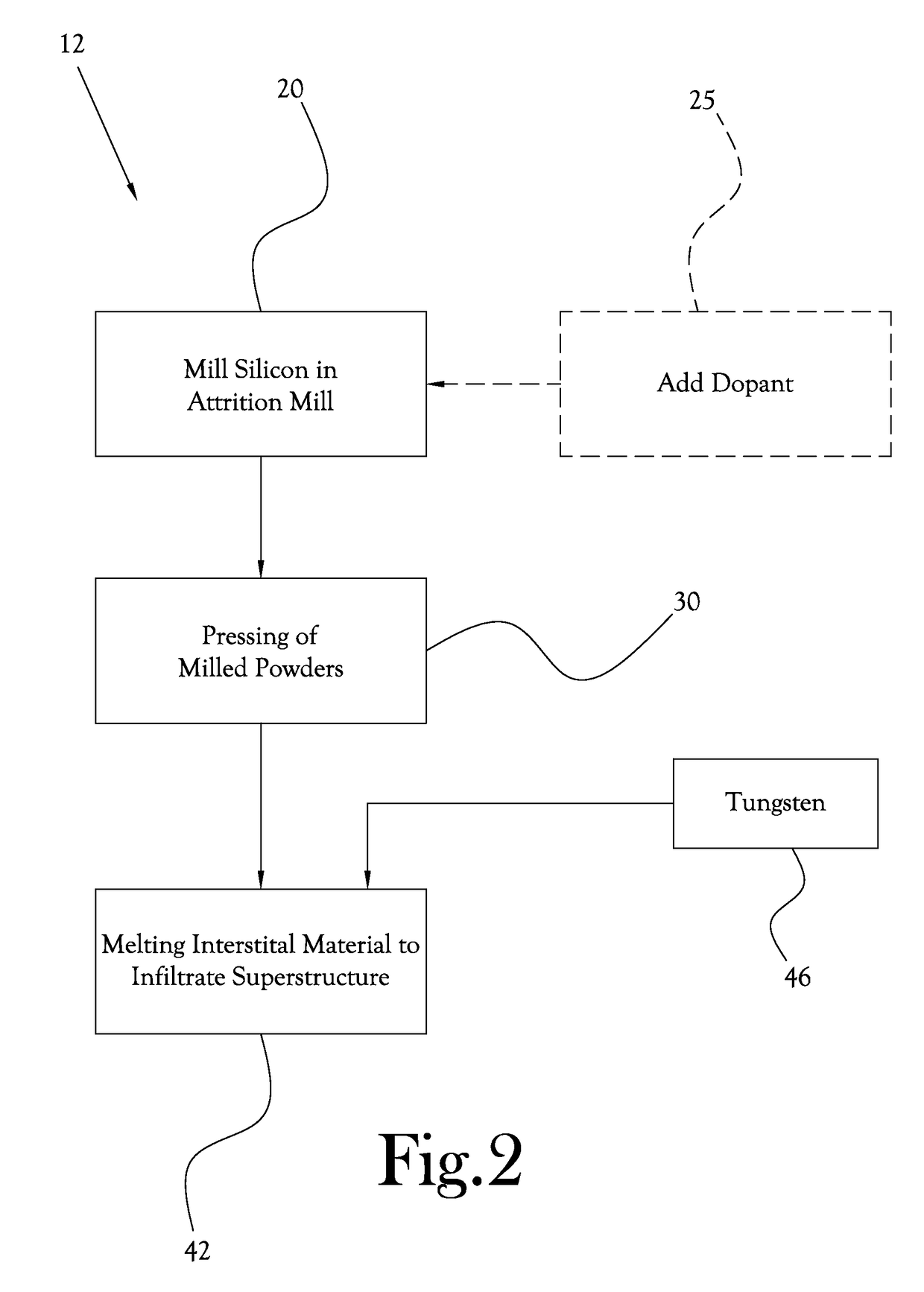

[0060]Disclosed herein are methods and processes to fabricate high capacity, durable electrodes, and particularly anodes, for lithium secondary batteries.

[0061]Also disclosed herein are methods and processes that encompass the use a high-purity, porous silicon sintered into a structure that will achieve a very high capacity.

[0062]Lithium secondary batteries have particular application in the field of battery-powered and / or hybrid vehicles. The challenge in this context is to provide a lithium secondary battery for an automobile or similar vehicle, where that lithium secondary battery will charge quickly; be light weight; allow a vehicle to travel on the order of 300 miles on one charge; and be reusable (i.e. rechargeable) over a long life—generally 10,000 cycles or more.

[0063]At the present time, lithium ion secondary batteries are limited by the low function / low capacity of current electrodes. Using silicon can increase electrode output by an order of magnitude, but to be competiti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| median diameter | aaaaa | aaaaa |

| median diameter | aaaaa | aaaaa |

| median particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com