Rebreather control parameter system and dive resource management system

a control parameter and control parameter technology, applied in non-electric variable control, waterborne vessels, instruments, etc., can solve the problems of oxygen toxicity, death of diver, unconscious diver, etc., and achieve the effect of minimizing decompression time and minimizing gas venting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

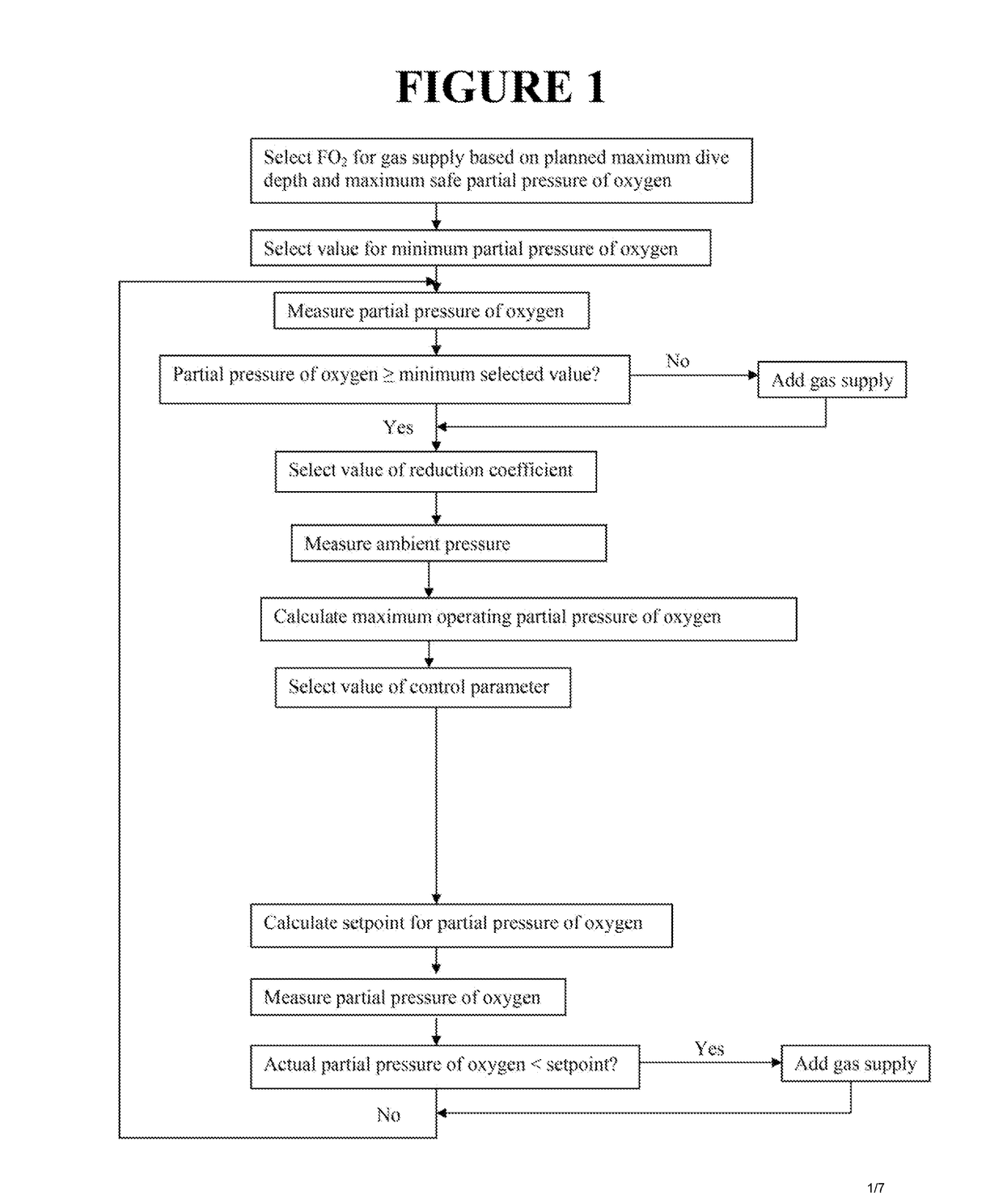

Method used

Image

Examples

Embodiment Construction

[0038]A rebreather system in accordance with certain embodiments includes a breathing loop comprising a scrubber canister, a counterlung, a sensor for measuring ambient pressure, a pressure transducer for determining depth, a sensor for measuring partial pressure of oxygen in the rebreather breathing loop, a valve for adding a gas supply to the rebreather breathing loop, a power source, connecting hoses, check valves, a processor adapted to receive data, execute calculations, send signals to display data and warning indicators and control the actuation of the addition valve, a gas supply pressure regulator and a gas supply consisting of either a single high-pressure source containing an oxygen-enriched gas mixture or a source containing pure oxygen in conjunction with a source containing diluent gas. In certain embodiments, the rebreather system comprises a passive mechanical addition valve that is adapted to add the gas supply to the rebreather breathing loop at a fixed rate if amb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com