Apparel Power System and Method of Using the Same

a technology of power system and wearable apparel, which is applied in the direction of gloves, cycle equipment, protective garments, etc., can solve the problems of inability to maintain the selected temperature of the thermo-regulated apparel, uncomfortable wear, and inability to provide a system and process for heating and cooling that can be incorporated into wearable apparel for a wide variety of uses, so as to achieve the effect of not affecting the esthetic of the components and without any negative impact on the pilot comfor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038]A novel apparel power system and method of using the same will be described hereinafter. Although the invention is described in terms of specific illustrative embodiments, it is to be understood that the embodiments described herein are by way of example only and that the scope of the invention is not intended to be limited thereby.

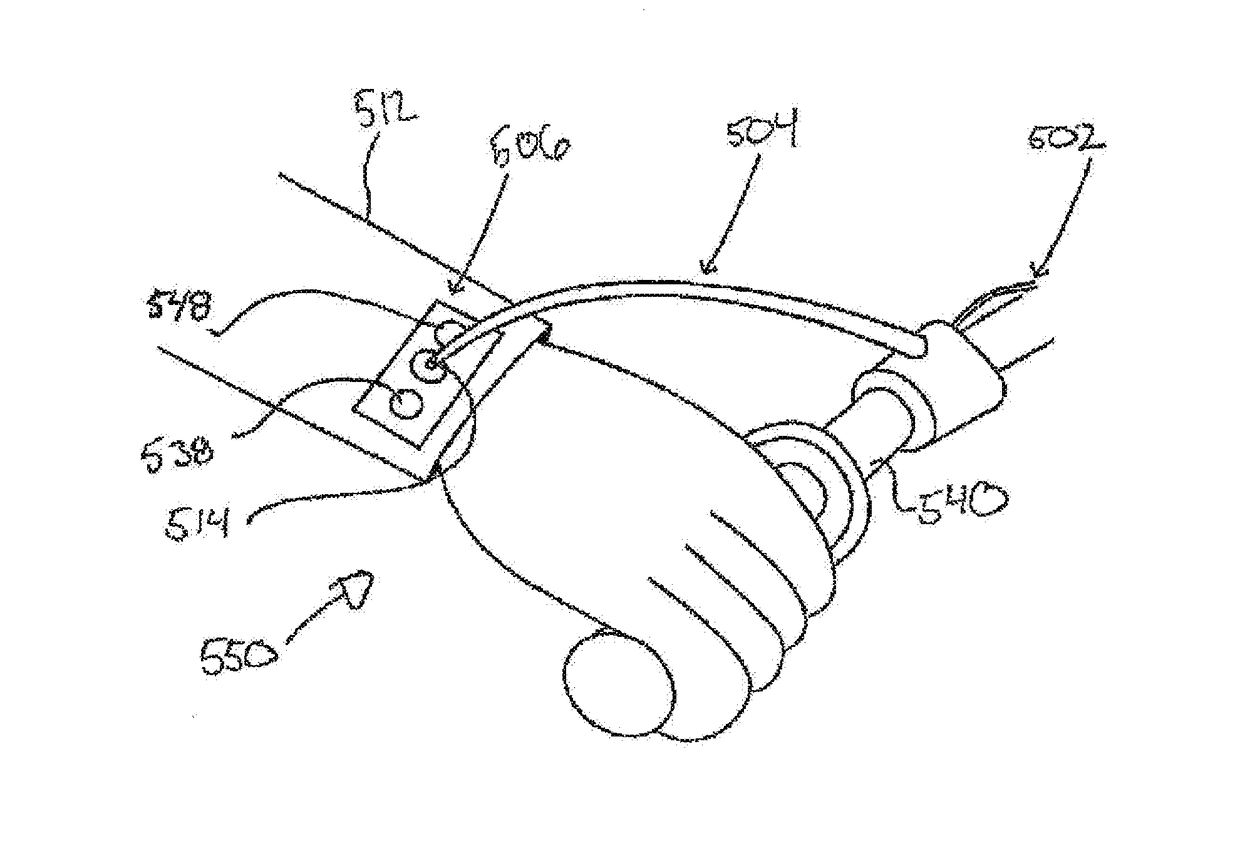

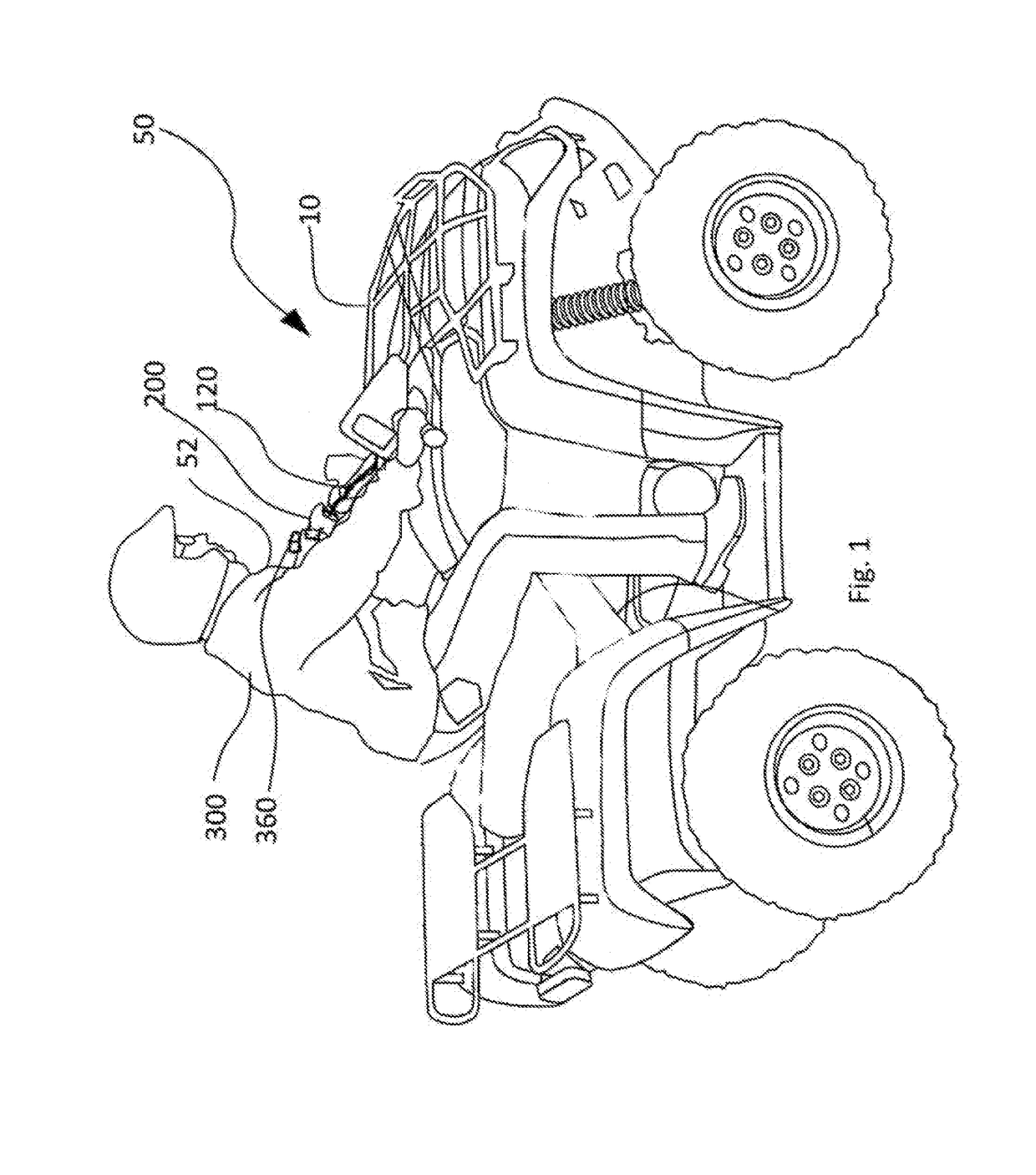

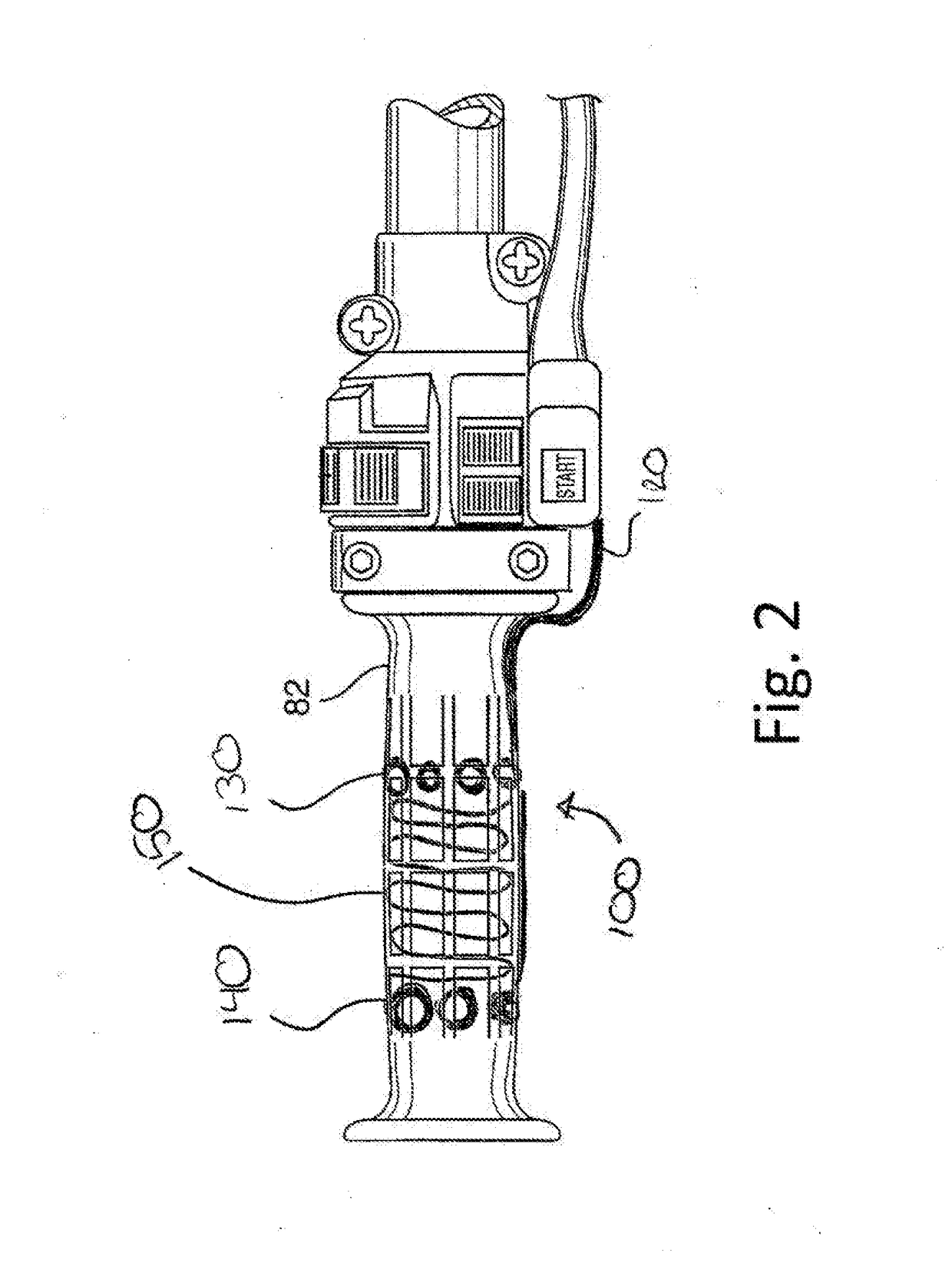

[0039]Referring now to FIG. 1, according to one embodiment, the system comprises a power source (the vehicle), a vehicle connector (typically attached to the handle bar), a vehicle power to connector interface, an apparel connector, electrical connection means between the apparel connector and a power storage (for example a battery) attached or integrated to the apparel and / or to one or more accessories requiring the power.

[0040]The apparel power system 50 comprises an energy transfer means linking the apparel worn by a user 52 of a vehicle 10 to a power generating source, typically the vehicle's 10 own energy generation system. The energy transfer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com