Noise-Making Device

a noise-making device and noise-making technology, applied in the direction of toys, rattles, packaging, etc., can solve the problems of large or cumbersome carrying, and the self-limiting of vocal expressions of limited duration and volum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

third embodiment

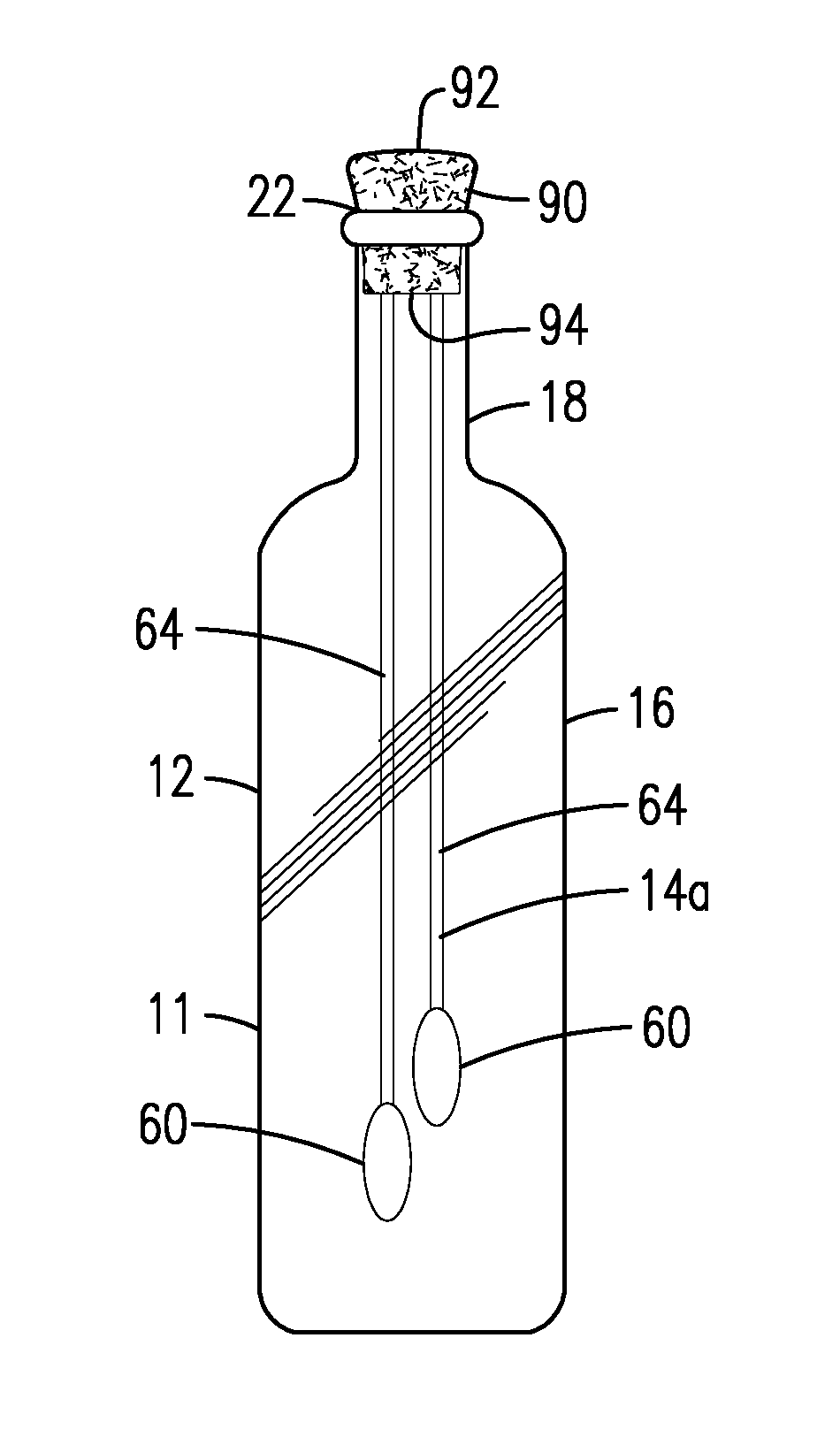

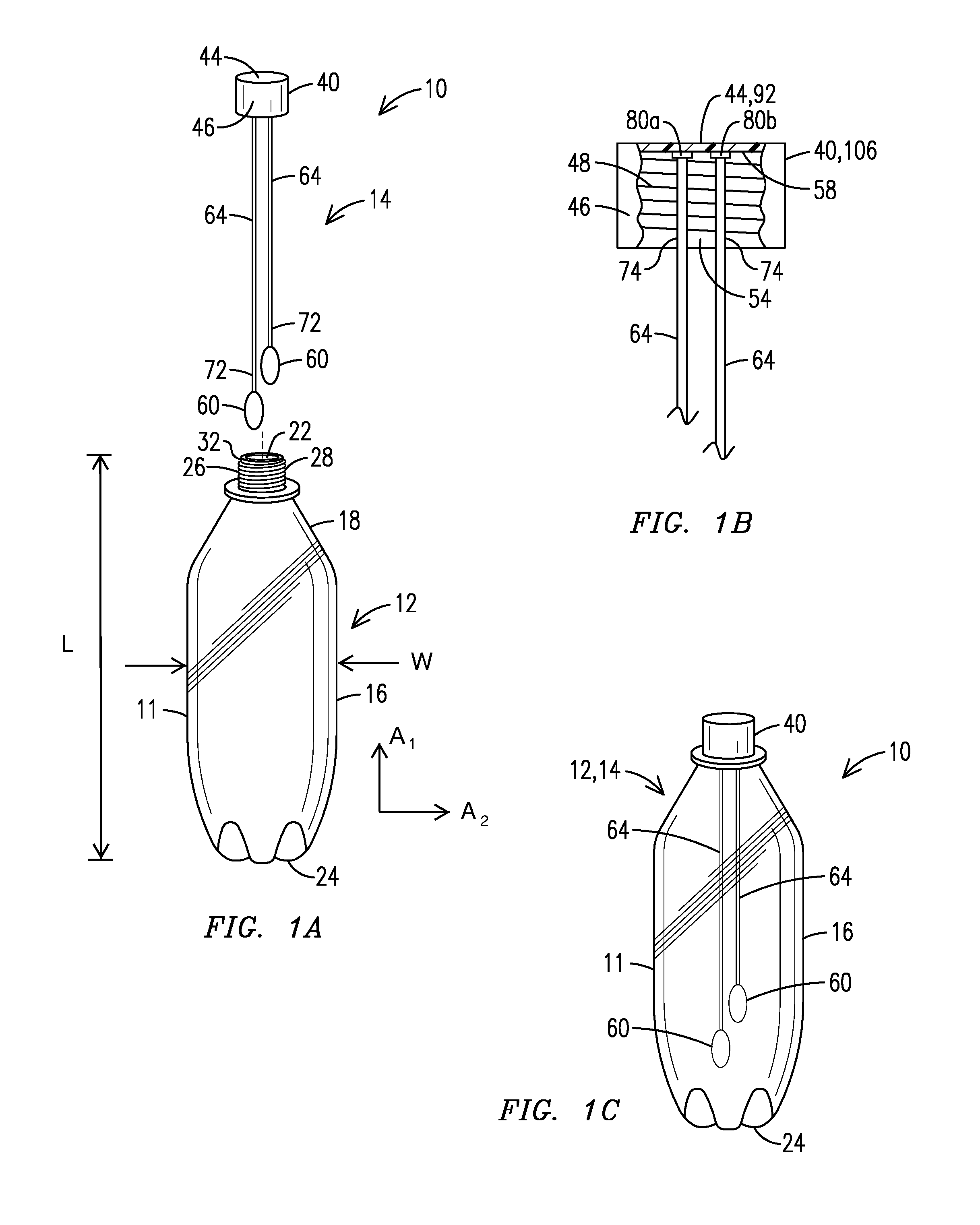

[0071]FIGS. 3A through 3D illustrate features of a noise-making assembly 14a according to the invention. In lieu of providing the cap 40, two masses 60, each attached to a rod member 64, are suspended from a cap in the form of a stopper 90. As shown in the figures, the two illustrated rod members are of different lengths so that one rod member extends closer to the second end than does the other rod member. Also as shown in the figures, the exemplary stopper may have a slightly tapered profile in which an upper stopper surface 92 has a greater outside dimension than a lower stopper surface 94. When the stopper 90 is installed in a bottle opening 22 the upper stopper surface 92 is positioned along the first bottle end 26 near the opening 22 (e.g., outside the opening), while the lower stopper surface 94 is positioned within the bottle interior along or adjacent the neck region 18 and near the opening 22.

[0072]The stopper 90 may comprise a size-adjustable rubber-like mass or a cork bo...

fourth embodiment

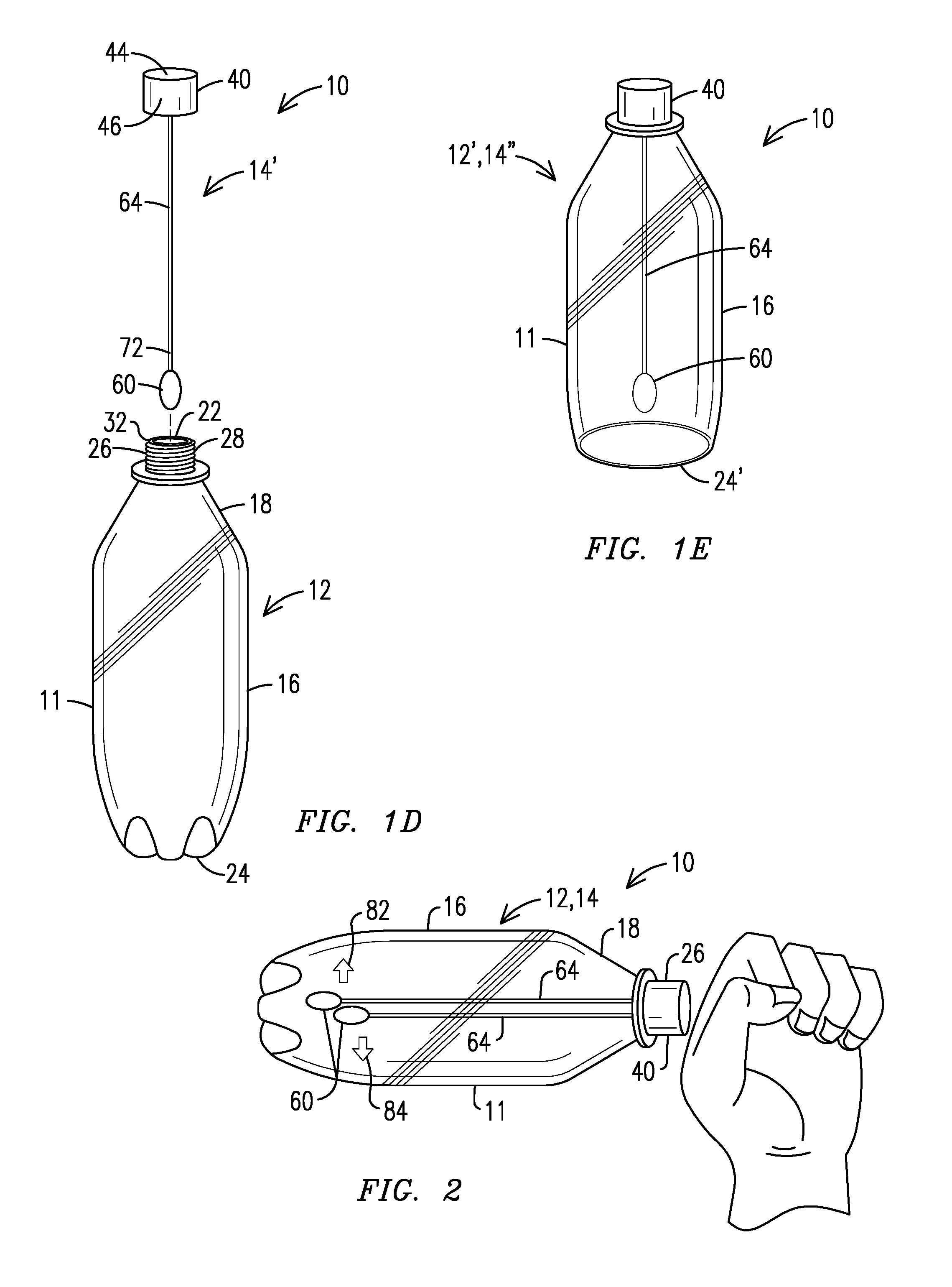

[0073]In addition to providing masses 60 and rod members 64 suspended from a cap 40 or a stopper 90, a noise-making assembly 14b according to the invention includes a handle 104. The handle 104 may extend from the upper surface 44 / 92 of a cap or a stopper and may be integrally formed with the cap or stopper, e.g., in a molding process. FIGS. 4A and 4B illustrate one example of the assembly 14b comprising a cap 106, having features like the cap 40. With reference to FIG. 1B, the cap 106 includes the cylindrically shaped wall 46 and an interior surface 58 of the circular shaped cap top 44 which adjoins the interior wall surface 54. The cap 106 also includes mating threads 48 formed along the interior surface 54 of the cap wall 46. With this arrangement the cap 40 may be screwed on to the first end 26 of the bottle 12 in like manner to that described for the cap 40 with reference to FIG. 1.

embodiment 10

[0074]Like the embodiment 10, the rod members 64 of the noise-making assembly 14b are attached to and extend away from fixation points 80a, 80b to suspend the masses 60 from the cap 106. The handle 104 extends in a direction away from the rod members 64 and masses 60. In one implementation, the handle 104 may be integrally formed with the cylindrically shaped wall of the cap 106, e.g., as an extension of the cap wall 46. When the handle 104 and cap 40 are integrally formed, e.g., in a molding process, the portion corresponding to the cap wall 46 shown in FIG. 1 is a portion of a larger wall 108 which provides the handle 104 as well.

[0075]With the handle 104 extending away from the bottle opening 22, the hand position shown in FIG. 2 for holding a bottle 12 containing a noise-making assembly may also be applied to the handle 104. Instead of applying the hand to the first bottle end 26 or the narrowing neck region 18 of the bottle, the hand may grasp the handle 104 to impart motion to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com