Cable guide for wire basket cable tray

a cable tray and wire basket technology, applied in the direction of electrical appliances, instruments, optics, etc., can solve the problems of cable tangles, difficult cable installation, snapping or damaging cables,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

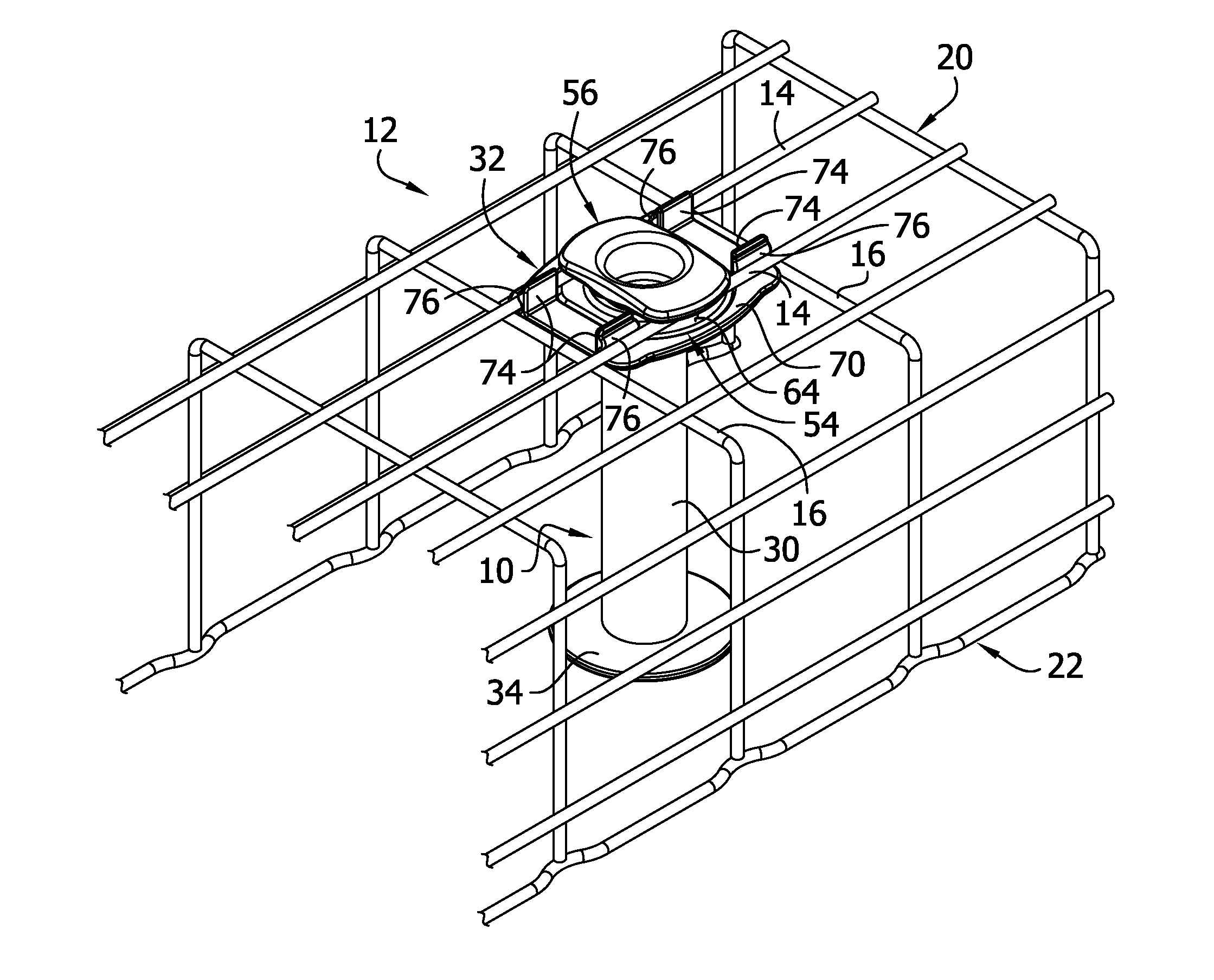

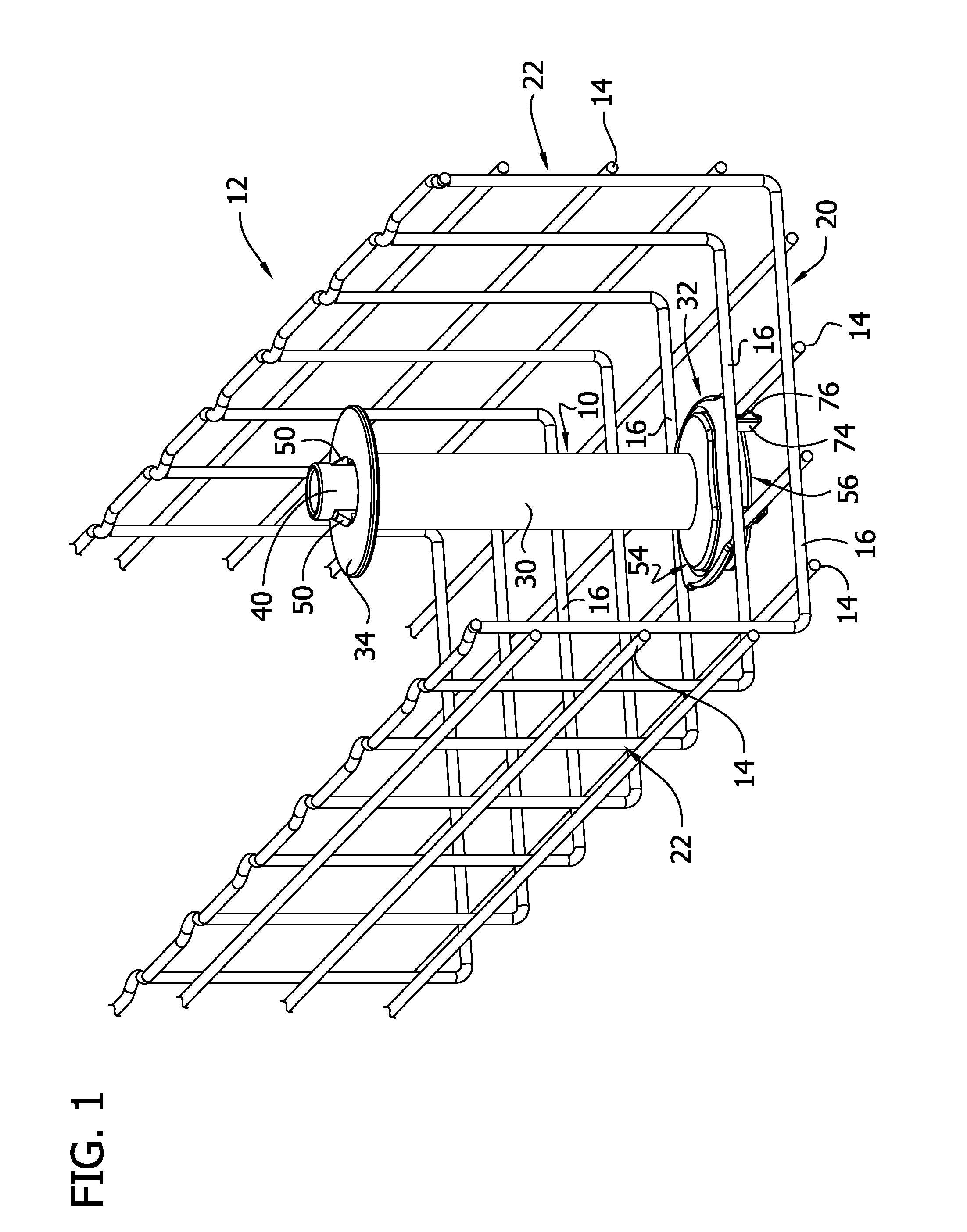

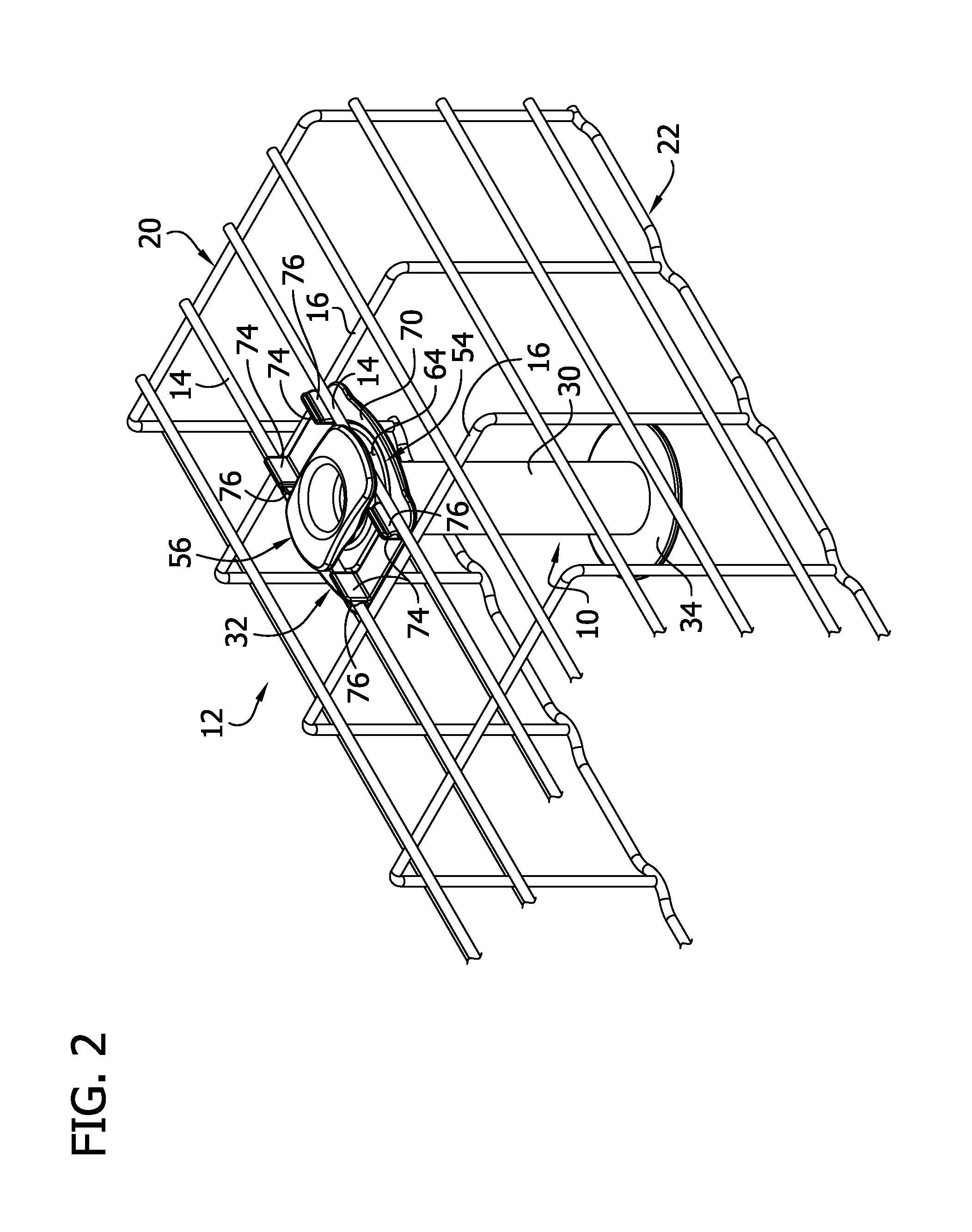

[0021]Referring to FIGS. 1 and 2 of the drawings, a cable guide, generally indicated at reference numeral 10, is attached to a wire basket cable tray, generally indicated at reference numeral 12. The cable guide 10 is used to guide cables or wires (not shown) along the wire basket cable tray 12, particularly around corners or other bends along the run of the cable tray. As explained in more detail below, the cable guide 10 is readily attachable to the wire basket cable tray 12 without the use of additional tools or fasteners.

[0022]Referring to FIG. 3, the wire basket cable tray 12 includes a plurality of longitudinal wires 14 extending along a length of the cable tray, and a plurality of transverse wires 16 secured to the longitudinal wires and extending generally transverse to the longitudinal wires. In the illustrated embodiment, the transverse wires 16 are secured on upper portions of the longitudinal wires 14, although the transverse wires may be secured to the lower portions of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com