Poppet valve

a technology of poppet valve and valve body, which is applied in valve arrangements, machines/engines, mechanical equipment, etc., can solve the problems of energy loss, cooling loss, and temperature drop caused by cooling loss inside the combustion chamber that cannot be avoided, and achieve the effect of reducing the loss of combustion efficiency due to cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]Next, an embodiment of the present invention is described based on examples.

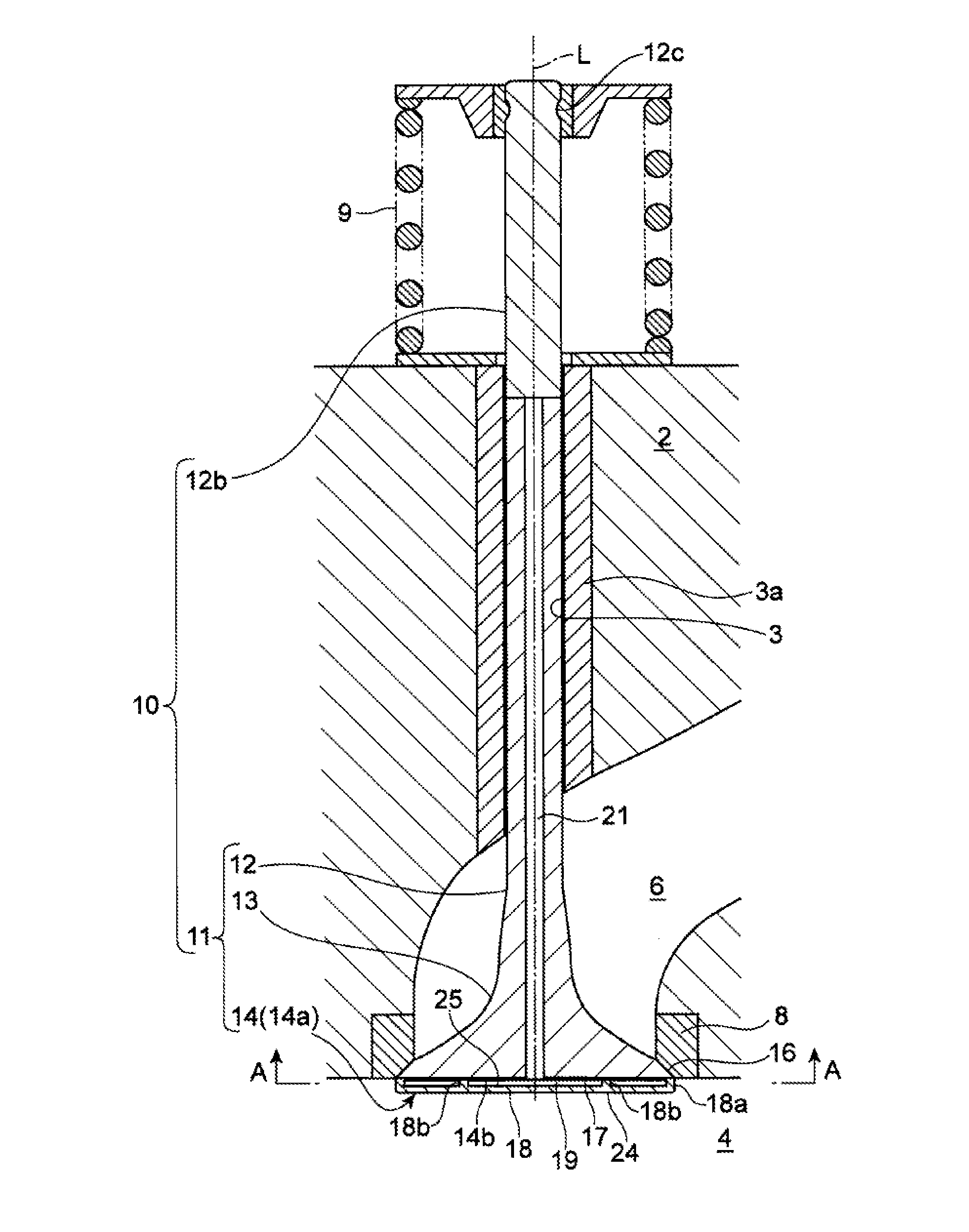

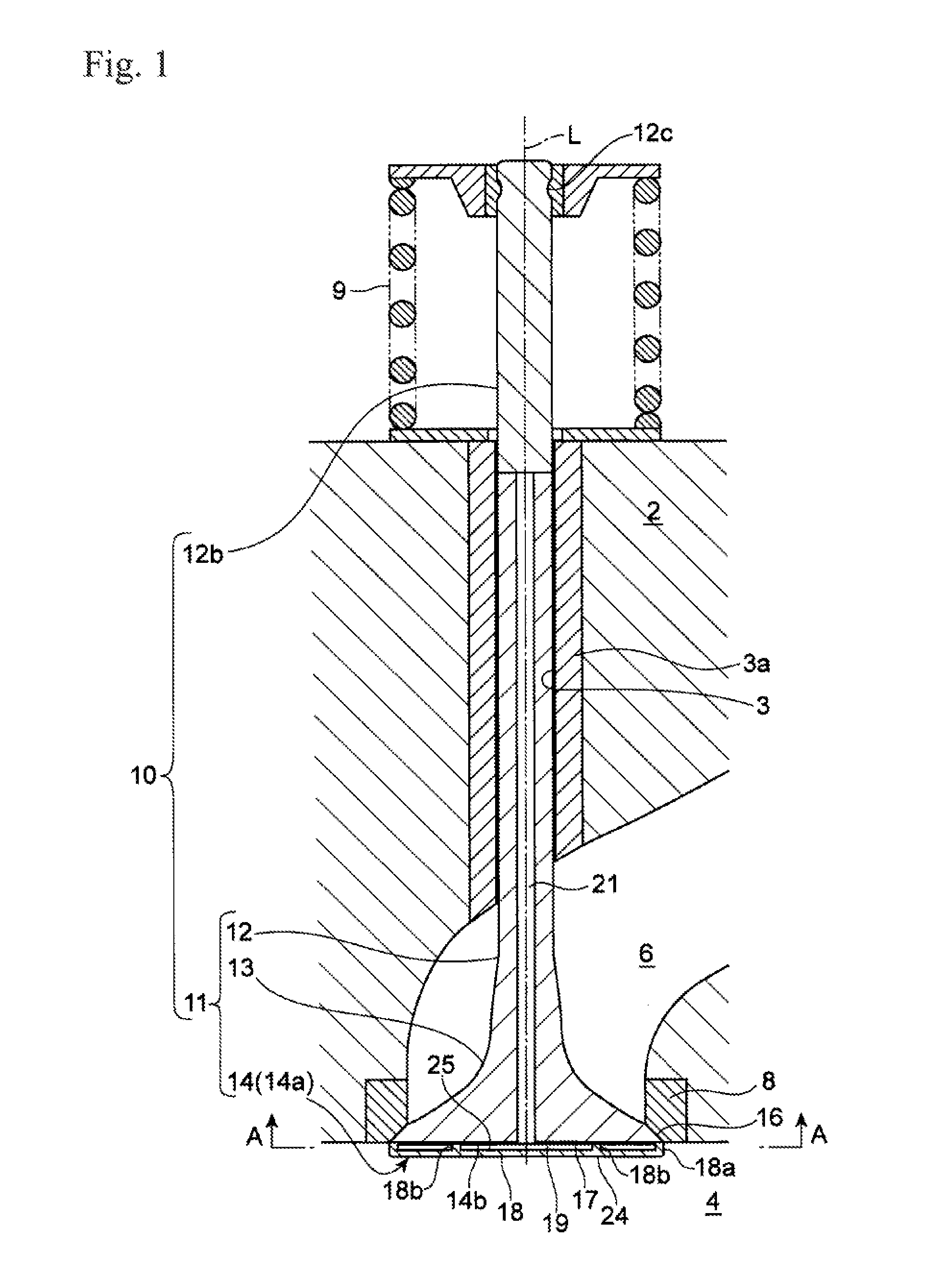

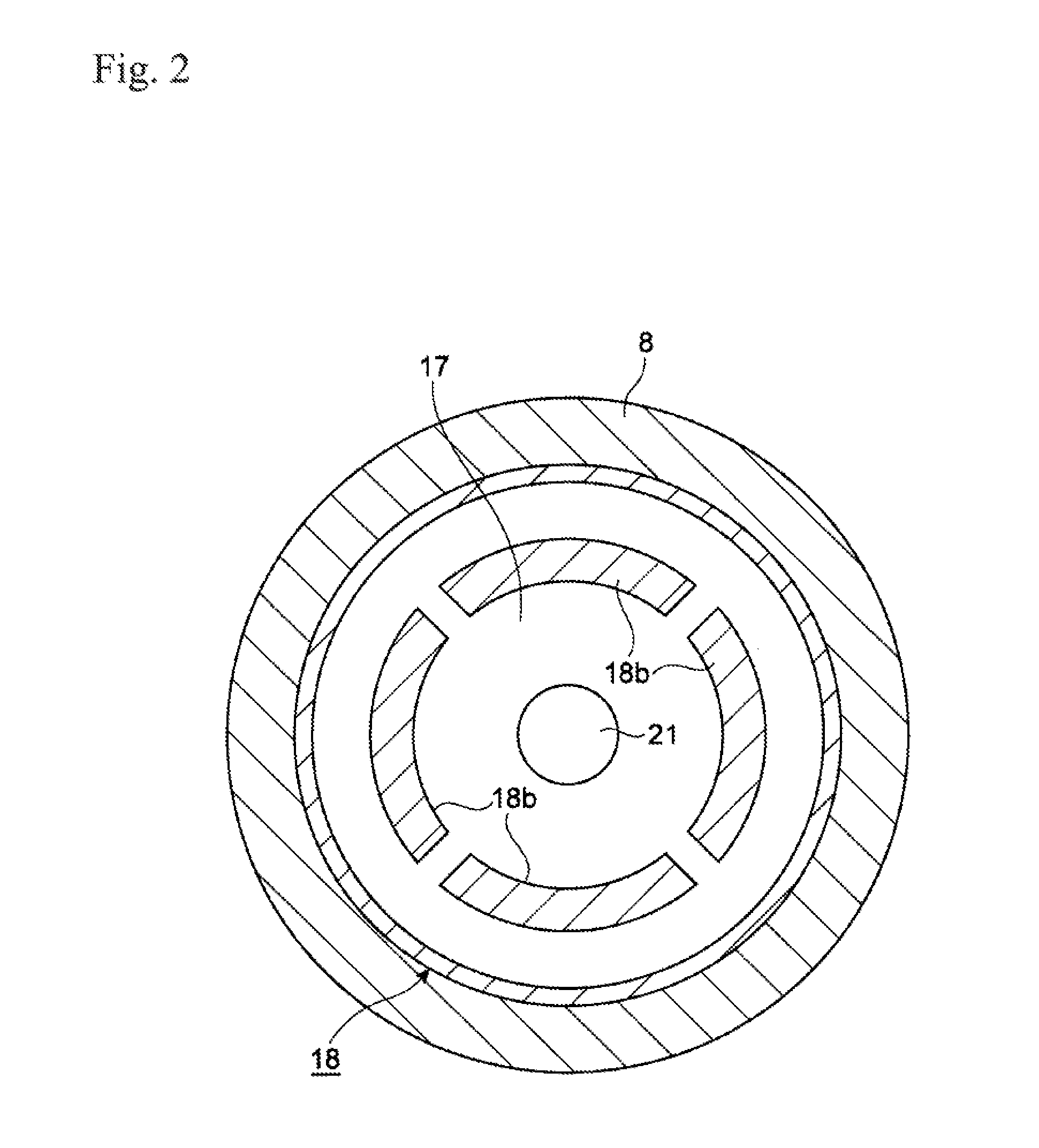

[0031]FIG. 1 and FIG. 2 show a hollow poppet valve for an internal combustion according to a first example of the present invention.

[0032]In FIG. 1, the reference sign 10 denotes a poppet valve made of a heat-resistant alloy, including a valve head portion 14 formed integrally with one end side of valve stem portion 12 extending straight via a rounded fillet portion 13 whose outer diameter gradually increases, and on an outer circumference of the valve head portion 14, a tapered valve seat face 16 is provided. A shell 11 is configured by forming a head portion shell 14a integrally with one end side of the stem portion 12.

[0033]On a upper end surface 14b on a head surface 24 side of the valve head portion 14, a radiation heat reflection surface (metal layer that insulates radiation heat) 17 made of a foil-shaped or sheet-shaped metal on which, preferably, a mirror surface is formed, is formed by thermal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com