Non-oriented electrical steel sheet and method of manufacturing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0086]An ingot having the components shown in Table 1 was melted in vacuum, and the ingot was heated to 1150° C. and was hot rolled at a hot rolling finish temperature of 875° C. and a coiling temperature of 630° C., thereby producing a hot-rolled steel sheet having a sheet thickness of 2.0 mm. The hot-rolled steel sheet was subjected to hot-rolled sheet annealing, was subjected to pickling, and was cold-rolled at a rolling reduction of 75%, thereby producing a cold-rolled steel sheet having a sheet thickness of 0.50 mm. Heat treatments performed on the test materials and the precipitation states of observed precipitates are shown in Table 2, and the magnetic properties (magnetic flux density and core loss) of each of the obtained steel sheets are shown in Table 3. Evaluation results of core loss evaluated as VG for very good, G for good, F for effective, and B for level in the related art are also shown in Table 3.

[0087]In addition, the evaluation of magnetic properties was perform...

example 2

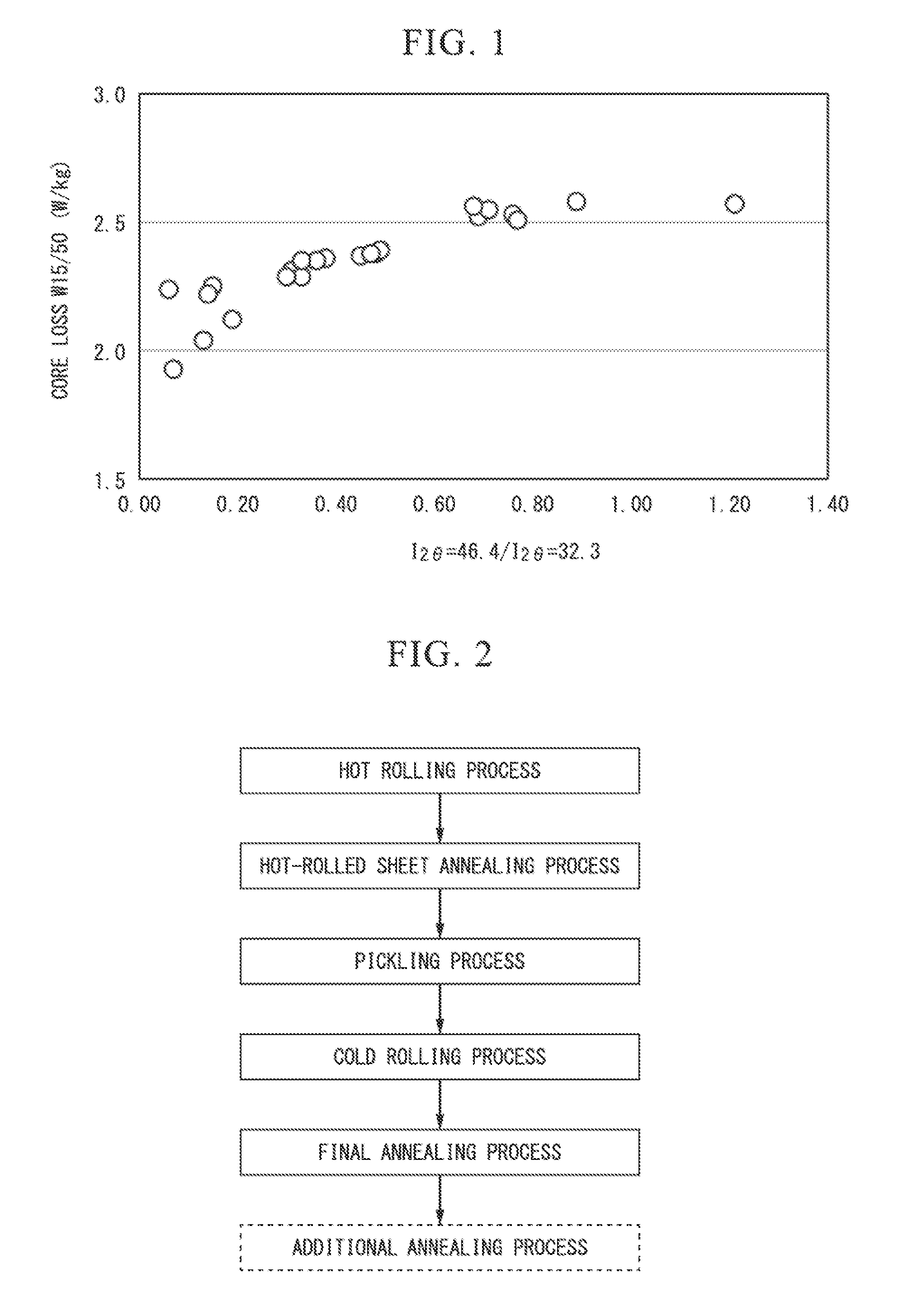

[0096]An ingot having the chemical components shown in Table 4 was melted in vacuum, and the ingot was heated to 1150° C. and was hot rolled at a hot rolling finish temperature of 850° C., thereby producing a hot-rolled steel sheet having a sheet thickness of 2.3 mm. The hot-rolled steel sheet was subjected to hot-rolled sheet annealing, was subjected to pickling, and was cold-rolled at a rolling reduction of 85%, thereby producing a cold-rolled steel sheet having a sheet thickness of 0.5 mm. Thereafter, final annealing was performed at a holding temperature of T1+50° C. for a holding time of 45 seconds. Thereafter, furnace cooling was performed so that the average cooling rates between T1° C. and T2° C. and between T2° C. and T3° C. were respectively 35° C. / sec and 15° C. / sec. X-ray diffraction results, the precipitation states of precipitates, magnetic properties (magnetic flux density and core loss), brittleness, and overall evaluation results are shown in Table 5.

[0097]Regarding...

example 3

[0099]An ingot having the same components as Steel type No. H23 shown in Table 4 was heated to 1100° C. and was hot-rolled at a finish temperature of 850° C. and a coiling temperature of 630° C., thereby producing a hot-rolled sheet having a sheet thickness of 2.0 mm. The hot-rolled sheet was subjected to final annealing under the conditions shown in Table 5, and was subjected to hot-rolled sheet annealing at 1000° C. for 120 seconds in some examples. Other manufacturing conditions, X-ray diffraction results, the precipitation states of precipitates, and the evaluation results of magnetic properties (magnetic flux density and core loss) are shown in Table 6. Regarding X-ray diffraction, measurement of the magnetic properties, and measurement of the precipitates, the same evaluations as in Example 1 were performed.

TABLE 6FIRST FINALSECOND FINALANNEALINGAVERAGE COOLINGANNEALINGCALCURATEDHOLDINGRATE AFTER FINALHOLDINGTEMPERATURETEMPER-HOLDINGANNEALINGTEMPER-MANUFACTURESTEELT1T2T3ATURET...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com