Inductively Controlled Series Resonant AC Power Transfer

a series resonant ac and power transfer technology, applied in the direction of transformers/inductance circuits, transformers, electrical apparatuses, etc., can solve the problem of not being able to use control on the primary side, unable to precisely match the induced voltage of the pickup to the desired output voltage, and unable to meet the induced voltage of the pickup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

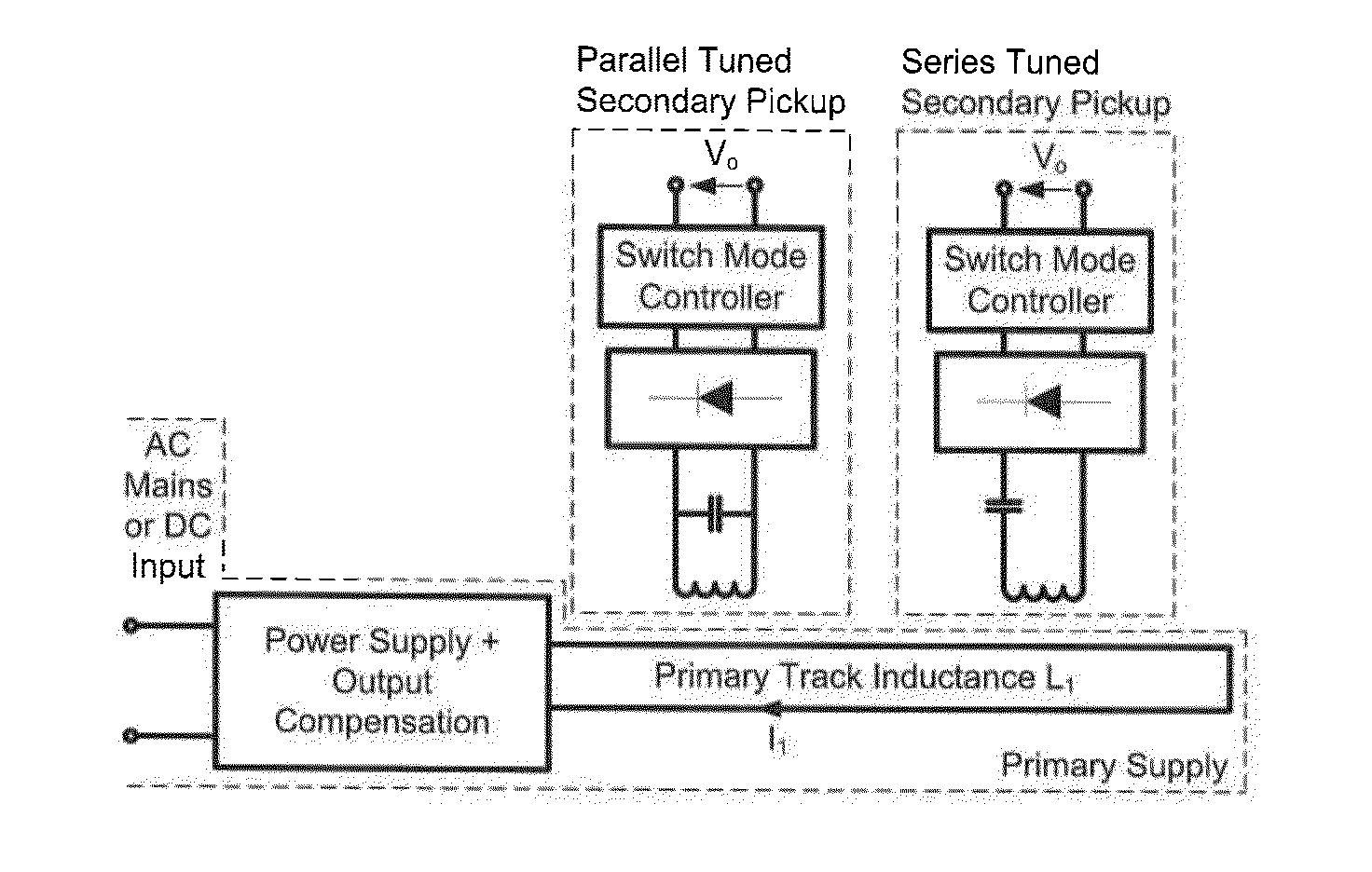

[0040]A new type of AC processing pickup illustrated herein exhibits excellent features such as simple circuitry, lower production cost and very high efficiency operation.

[0041]This specification discloses a new series AC processing pickup that uses an AC switch operating near ideal soft switching operating conditions to regulate the output voltage of the pickup directly. The output can be either controlled AC or DC depending on whether a rectifier is added to the AC output at the end of the resonant network.

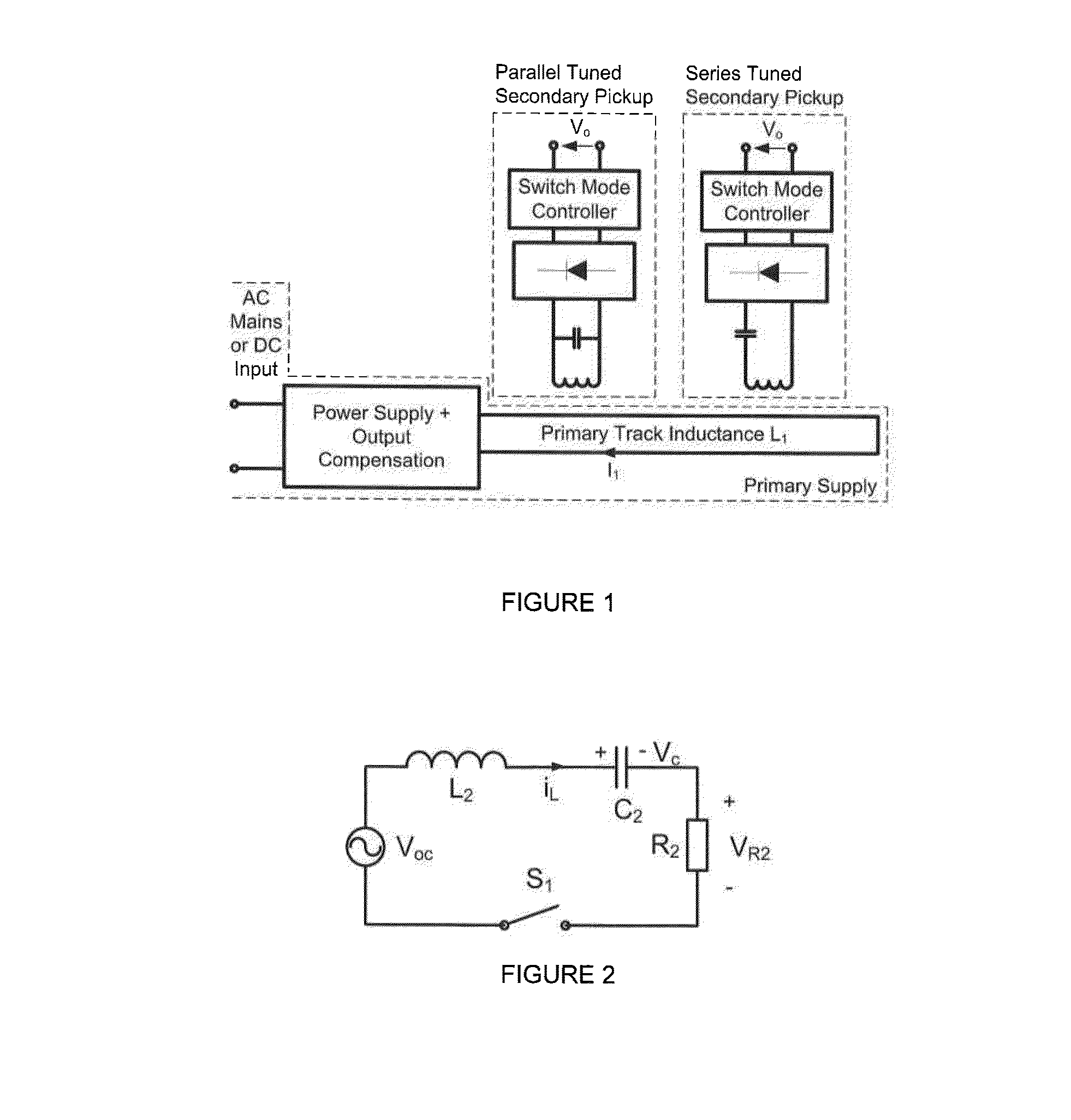

[0042]According to one embodiment of the invention a series AC processing pickup is shown in FIG. 2 with an AC output voltage (VR2). Capacitor C2 is tuned to inductor L2 at the frequency of the primary track current i1 to form a series resonant tank. The open circuit voltage source (Voc) represents the induced voltage of the pickup. For simplicity, switch S1 is drawn as an ideal AC switch and it is the basis for controlling the output voltage.

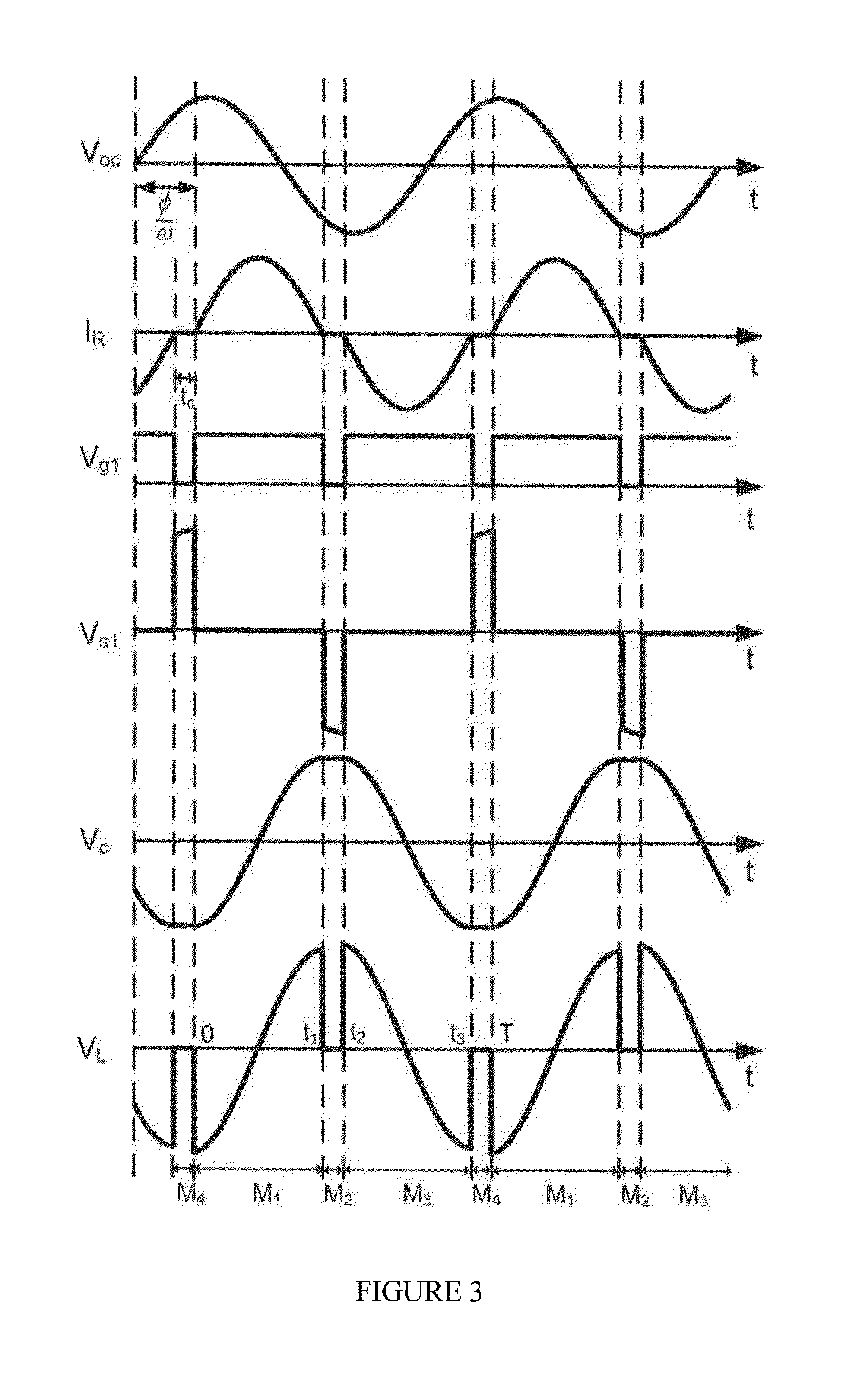

[0043]To illustrate the circuit's op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com