Winding apparatus for waveguide prototype mould and waveguide manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]Preferred embodiments of the present invention are described in detail below with reference to the accompanying drawings. All the accompanying drawings are simplified schematic figures, which merely describe the basic structure of the present invention in a schematic manner. Therefore, only elements related to the present invention are shown in the drawings, and the elements are not displayed according to the quantity, shape, or dimensional proportion during implementation. During practical implementation, there are options for design of the specifications, and the element arrangement may be more complex.

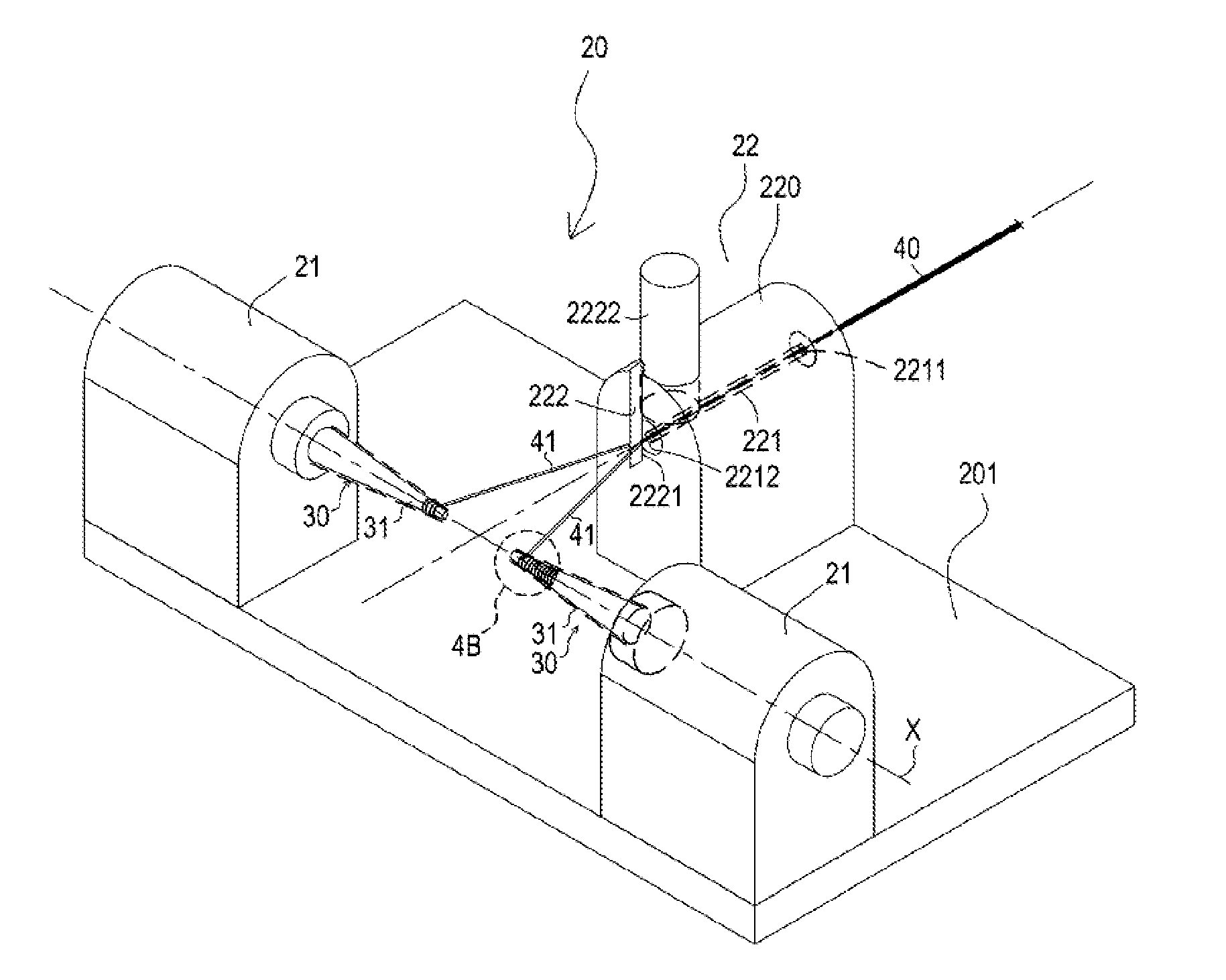

[0025]First, refer to FIG. 4A and FIG. 4B. This embodiment is a winding apparatus 20 for a waveguide (or referred to as corrugated horn) prototype mold 50; the waveguide prototype mould 50 is formed by treating a waveguide prototype 30 by the winding apparatus 20. The waveguide prototype 30 includes a rod body 31; a surface of the rod body 31 is periodically provided with radi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com