Binary refrigerating apparatus

a technology of refrigerating apparatus and binaries, which is applied in the direction of refrigerating machines, lighting and heating apparatus, compression machines with cascade operation, etc., can solve the problems of oil deterioration and sludge, and achieve the effect of solving combustibility concerns, reducing gwp value, and reducing gwp valu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

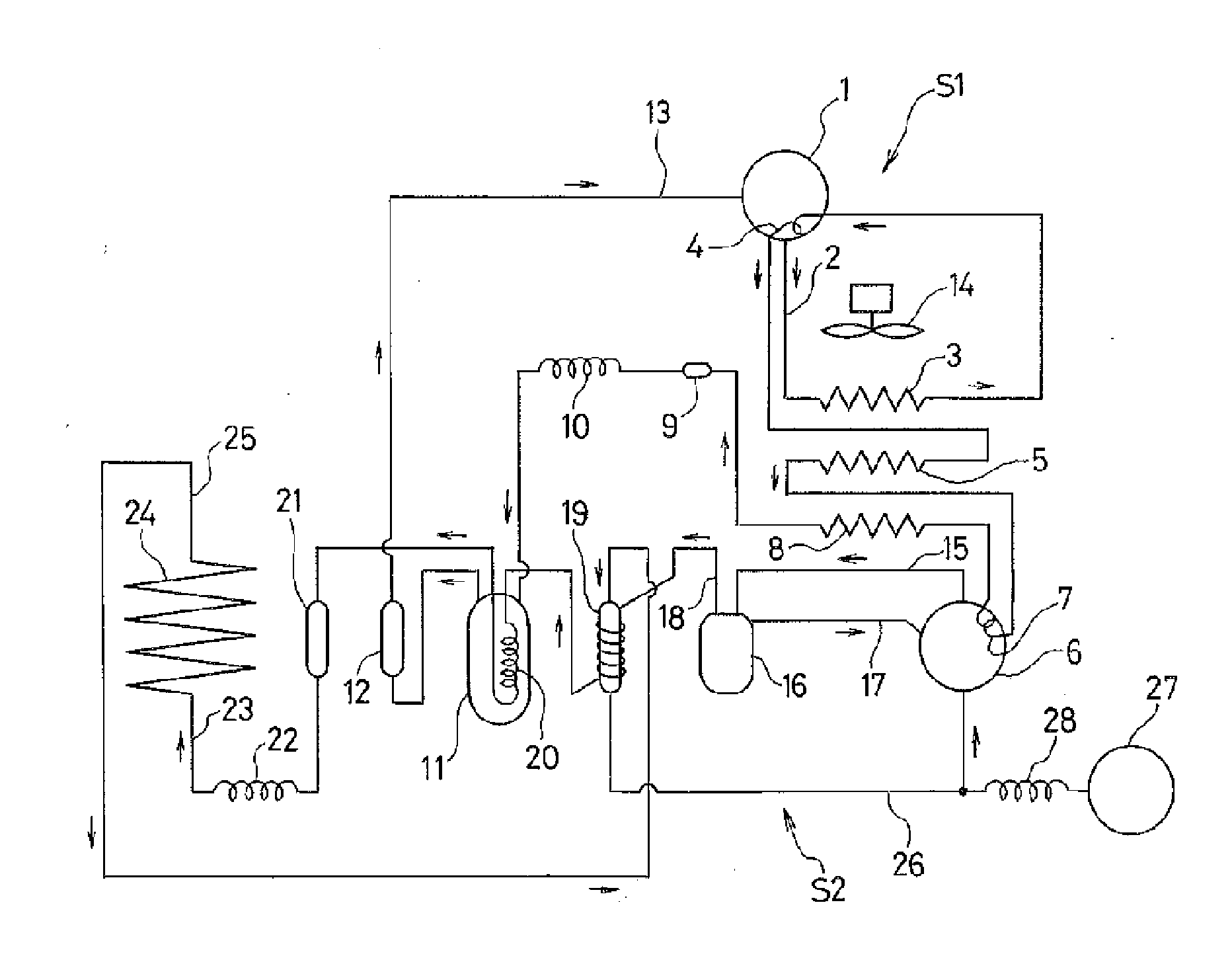

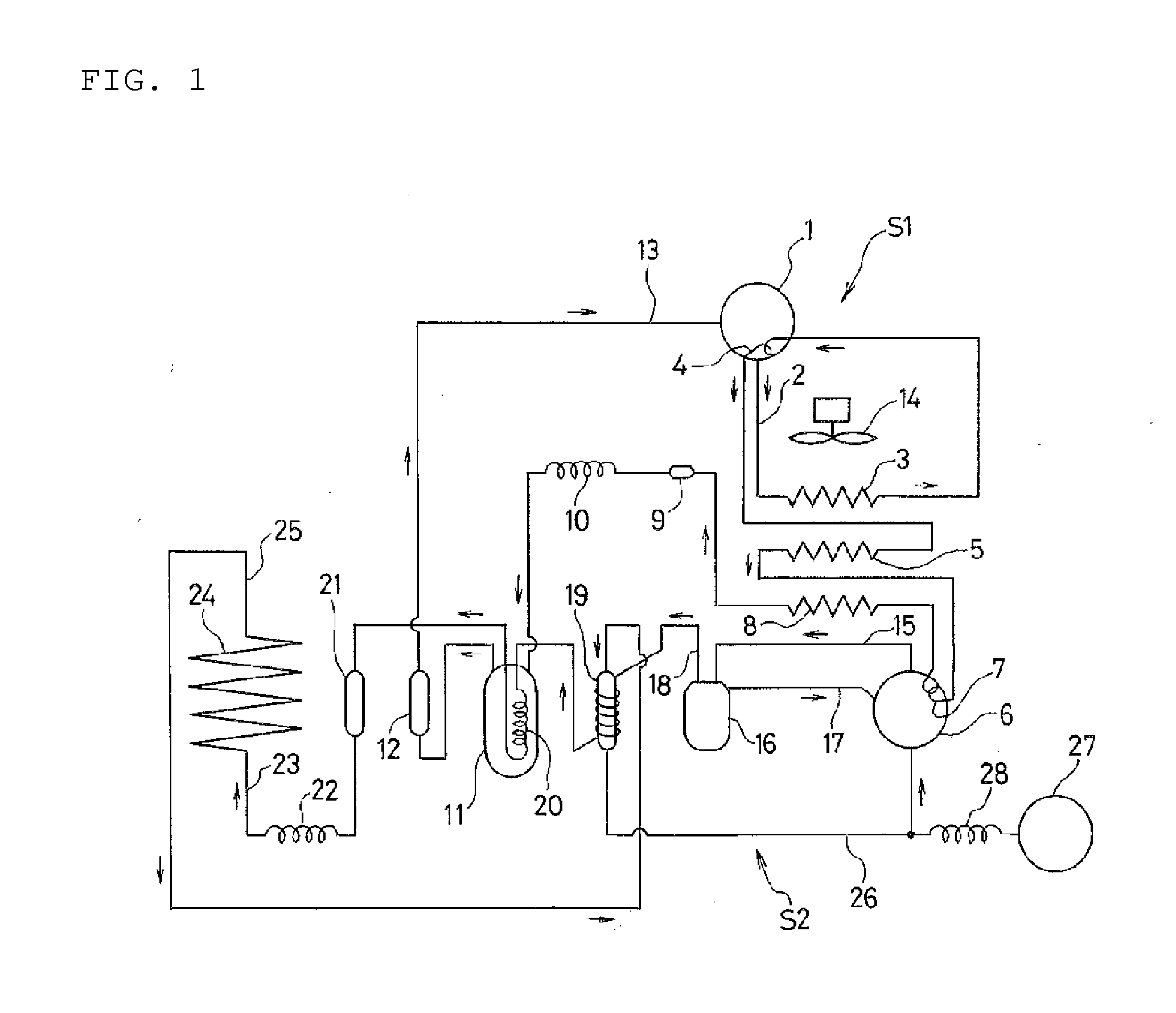

[0056]A binary refrigerating apparatus illustrated in FIG. 1 was stably and continuously operated at an outside air temperature of −10° C. for a long time. Thereafter, a cycle S1 and a cycle S2 were measured for temperatures at the points described below.

[0057]In the high-temperature-side refrigerant cycle S1, a refrigerant composition (GWP value: 1500 or less, boiling point: about −40° C. at atmospheric pressure) containing a non-azeotropic mixture comprising the refrigerant group of difluoromethane (R32), pentafluoroethane (R125), 1,1,1,2-tetrafluoroethane (R134a) and 1,1,3-trifluoroethane (R143a), and 1,1,1,2,3-pentafluoropentene (HFO-1234ze), was filled.

[0058]This refrigerant mixture condensed in each of condensers 3,5 and 8, was decompressed in a capillary tube 10, and flowed into a cascade condenser 11 to evaporate. The temperature at an exit of the cascade condenser 11 was −54.9° C.

[0059]On the other hand, in the low-temperature-side refrigerant cycle S2, a refrigerant compos...

example 2

[0061]In the high-temperature-side refrigerant cycle S1 and the low-temperature-side refrigerant cycle S2, the same refrigerant compositions as those in Example 1 were filled. Then, the binary refrigerating apparatus illustrated in FIG. 1 was stably and continuously operated at an outside air temperature of 31.1° C. for a long time. Thereafter, the cycle S1 and the cycle S2 were measured for temperatures at the points described below.

[0062]The temperature at an exit of the cascade condenser 11 was −35.9° C.

[0063]The temperature of the outlet-side pipe 15 at the refrigerant exit of the compressor 6 in the low-temperature-side refrigerant cycle S2 was 79.0° C.; the temperature of the inlet-side pipe 26 at the refrigerant inlet to the compressor 6 was 7.6° C.; the temperature of the entrance pipe 23 to the evaporator 24 was −90.2° C.; the temperature of the exit pipe 25 from the evaporator 24 was −81.8° C.; and the temperature inside the freezer (not shown) was −87.6° C.

[0064]Also, a r...

example 3

[0065]The binary refrigerating apparatus illustrated in FIG. 1 was stably and continuously operated at an outside air temperature of −0.4° C. for a long time. Thereafter, the cycle S1 and the cycle S2 were measured for temperatures at the points described above.

[0066]In the high-temperature-side refrigerant cycle S1, a refrigerant composition (GWP value: 1500 or less, boiling point: about −40° C. at atmospheric pressure) containing a non-azeotropic mixture comprising the refrigerant group of difluoromethane (R32), pentafluoroethane (R125), 1,1,1,2-tetrafluoroethane (R134a) and 1,1,3-trifluoroethane (R143a), and 1,1,1,2,3-pentafluoropentene (HFO-1234ze), was filled.

[0067]This refrigerant mixture condensed in each of the condensers 3,5 and 8, was decompressed in the capillary tube 10, and flowed into the cascade condenser 11 to evaporate. The temperature at the exit of the cascade condenser 11 was −53.1° C.

[0068]On the other hand, in the low-temperature-side refrigerant cycle S2, a re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com