Garment hanger

a technology for hanging racks and garments, applied in garments, garments, applications, etc., can solve the problems of shortening the strength of unable to design the hooks to have a sufficiently large diameter, and excessive load on the hooks of the hangers, so as to ensure the effect of attaching the hooks to the hangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0065]First, elements of a shirt to be hung by a garment hanger (hereinafter often referred to simply as a “hanger”) are explained with reference to FIG. 7.

[0066]As illustrated in FIG. 7, a dress shirt includes a collar 81 comprising a rear collar portion 82, a front collar portion 84, and a pair of side collar portions 83 connecting the front collar portion 84 and the rear collar portion 82 to each other. As mentioned below, the dress shirt is hung by the hanger in accordance with the preferred embodiments of the present invention.

[0067]A hanger 10 in accordance with the first embodiment is explained hereinbelow with reference to the drawings.

[0068]The hanger 10 holds the collar 81 and shoulders of a jacket, a shirt and so on.

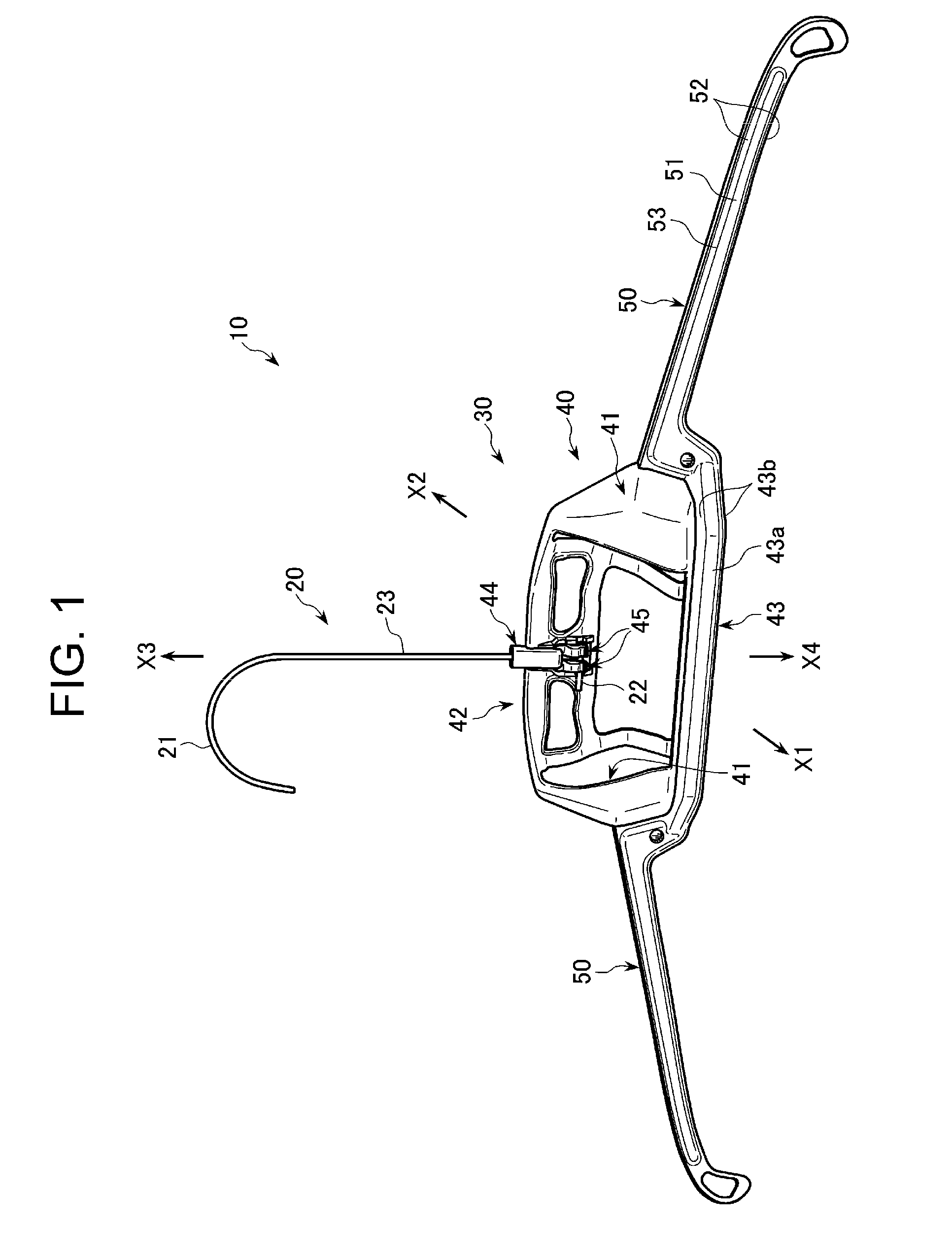

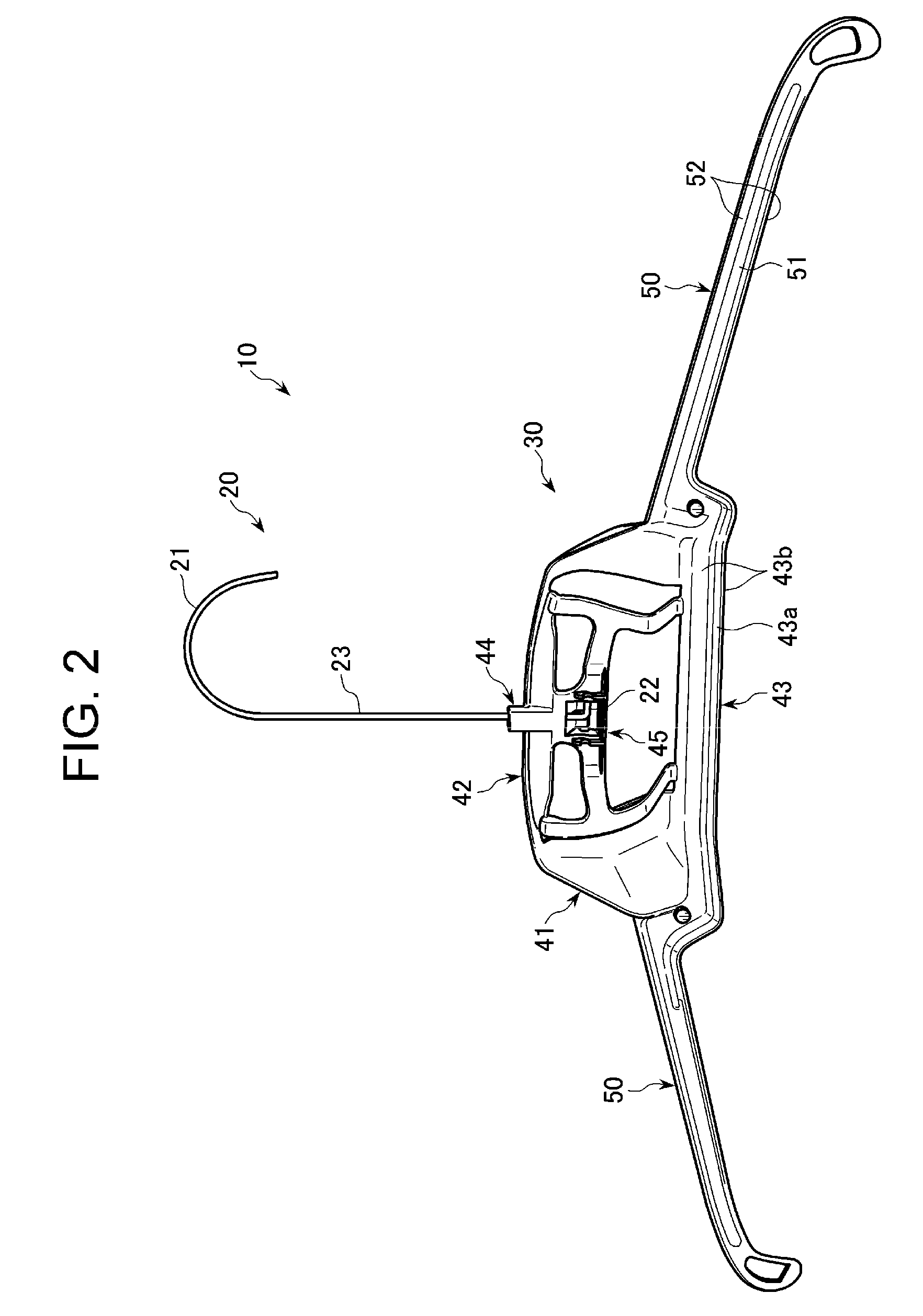

[0069]As illustrated in FIGS. 1 to 4, the hanger 10 includes a hook 20, and a hanger body 30 by which a dress shirt is held.

[0070]In the specification, a front or a forward relative to the hanger 10 indicates a direction X1, a rear or a back relative to the ha...

second embodiment

[0104]A hanger 10x in accordance with the second embodiment of the present invention is explained hereinbelow with reference to FIGS. 8 to 14. Parts or elements of the hanger 10x that correspond to those of the hanger 10 illustrated in FIGS. 1 to 4 have been provided with the same reference numerals, and operate in the same manner as corresponding parts or elements in the first embodiment, unless explicitly explained hereinbelow.

[0105]As illustrated in FIGS. 8 to 13, the shaft guide 44 in the hanger 10x in accordance with the second embodiment is designed to include a first shaft receiver 44a, a second shaft receiver 44b and a third shaft receiver 44c each of which receives the shaft portion 23 of the hook 20 along an axis of the shaft portion 23. The first shaft receiver 44a is located uppermost among the first to third shaft receivers, and the third shaft receiver 44c is located lowermost among the first to third shaft receivers.

[0106]The first shaft receiver 44a includes a groove...

third embodiment

[0143]A hanger 10y in accordance with the third embodiment of the present invention is explained hereinbelow with reference to FIGS. 18 and 19. Parts or elements of the hanger 10y that correspond to those of the hanger 10x illustrated in FIGS. 18 to 11 have been provided with the same reference numerals, and operate in the same manner as corresponding parts or elements in the second embodiment, unless explicitly explained hereinbelow.

[0144]As illustrated in FIGS. 18 and 19, the shaft guide 44y in the hanger 10y in accordance with the third embodiment is designed to include a second shaft receiver 44b and a third shaft receiver 44c each of which receives the shaft portion 23 of the hook 20 along an axis of the shaft portion 23. The second shaft receiver 44a is located above the third shaft receiver 44c. That is, the hanger 10y is designed not to include the first shaft receiver 44a relative to the shaft guide 44x of the hanger 10x in accordance with the second embodiment.

[0145]The sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com