Optical transceiver installing mt ferrule to mate with mpo connector

a technology of optical transceivers and ferrules, applied in the field of optical transceivers, can solve the problems of easy leakage of emi noises with higher frequencies from gaps and/or spaces with smaller frequencies, and achieve the effect of improving the reliability of optical coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

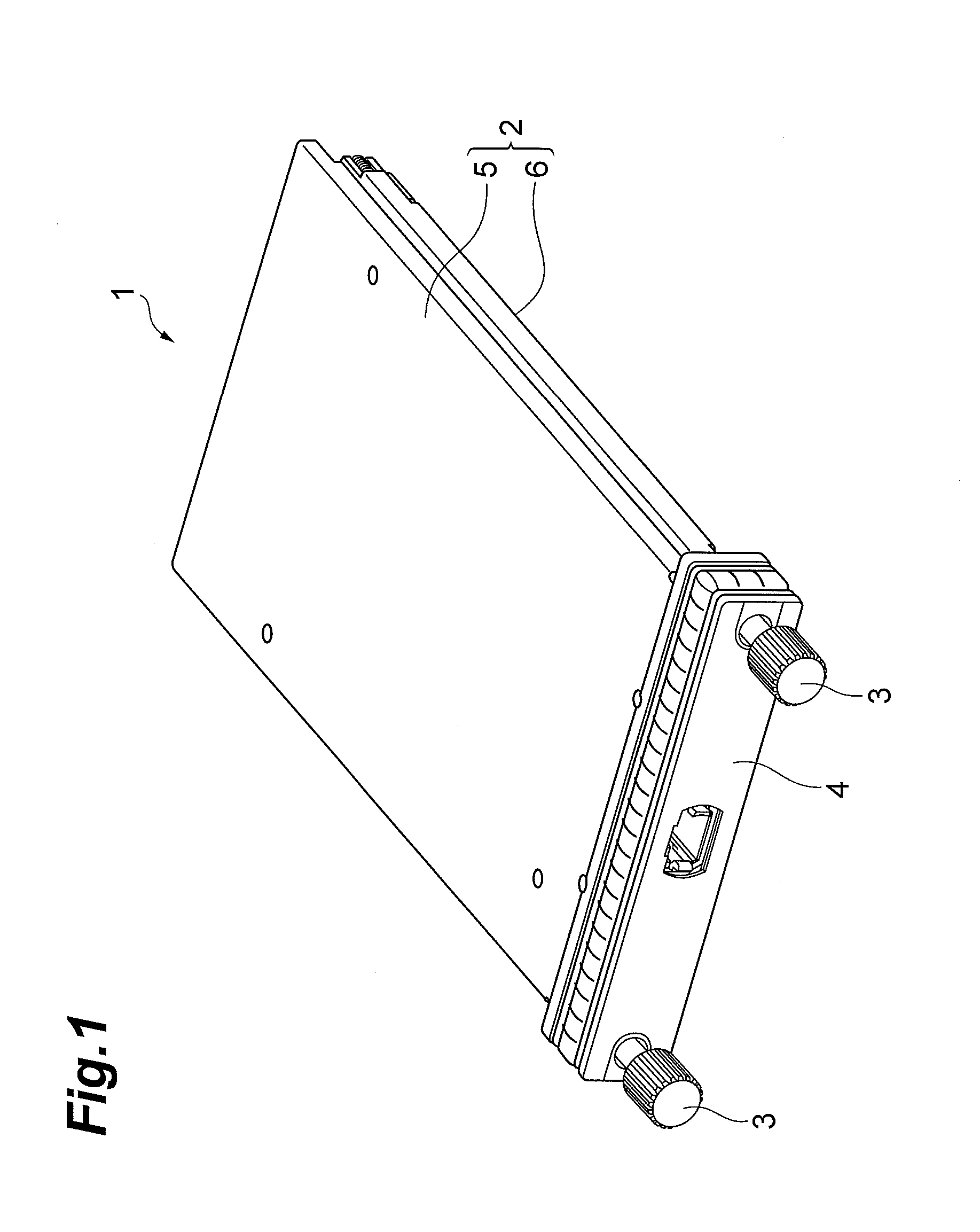

[0027]An optical transceiver 1 of the present application, as illustrated in FIG. 1, has a type of, what is called, the CFP following one of multi-source agreements (MSA) relating to optical transceivers. The optical transceiver 1, which is primarily installed in a data center, outputs and receives a plurality of optical signals via a plurality of optical fibers whose lengths are several hundred meters at most. The optical transceiver 1 implements with a plurality of vertical cavity surface emitting laser diodes (hereafter denoted as VCSEL) each emitting an optical signal with a wavelength shorter than one (1) micron as optical signal sources. The optical transceiver 1 comprises a housing 2, two screws 3, and a front cover 4. The housing 2 includes a top body 5 and a bottom body 6.

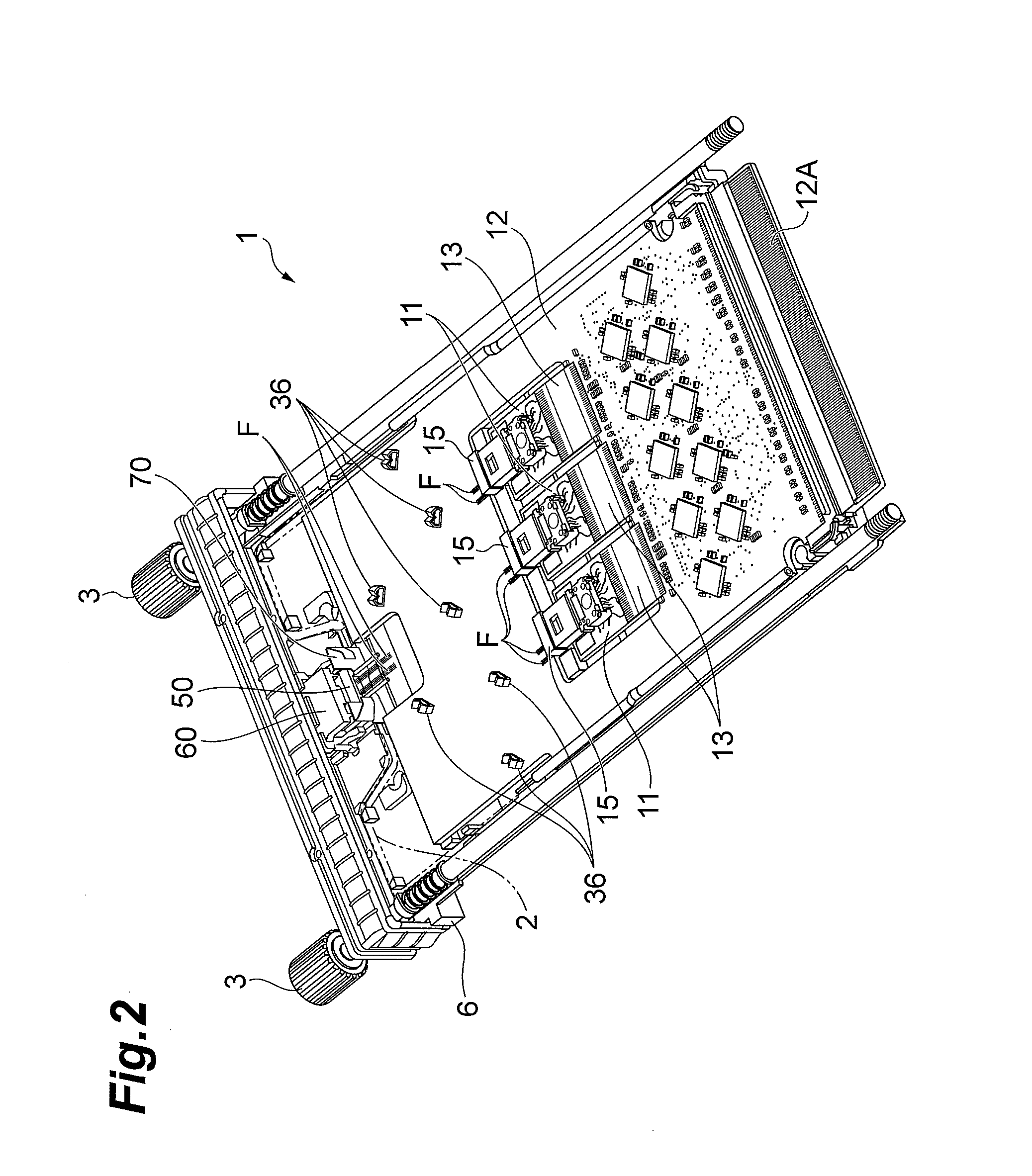

[0028]FIG. 2 is a perspective view of an inside of the optical transceiver 1. As shown in FIG. 2, the optical transceiver 1 encloses between two bodies, 5 and 6, three sub-boards 11 and a circuit board 12....

second embodiment

[0049]Next, another optical transceiver 101 according to the second embodiment of the present application will be described as referring to FIGS. 13 and 14.

[0050]FIG. 13 is a plan view showing the inside of the optical transceiver 101 of the second embodiment. The optical transceiver 101 provides another bottom body 106 that includes a modified receptacle portion 141 with a mechanics 170 to push the MT ferrule 50 in the optical receptacle 60 instead of the plate 70 in the former embodiment. Other arrangements of the modified optical transceiver 101 are substantially same as those of former embodiment 1.

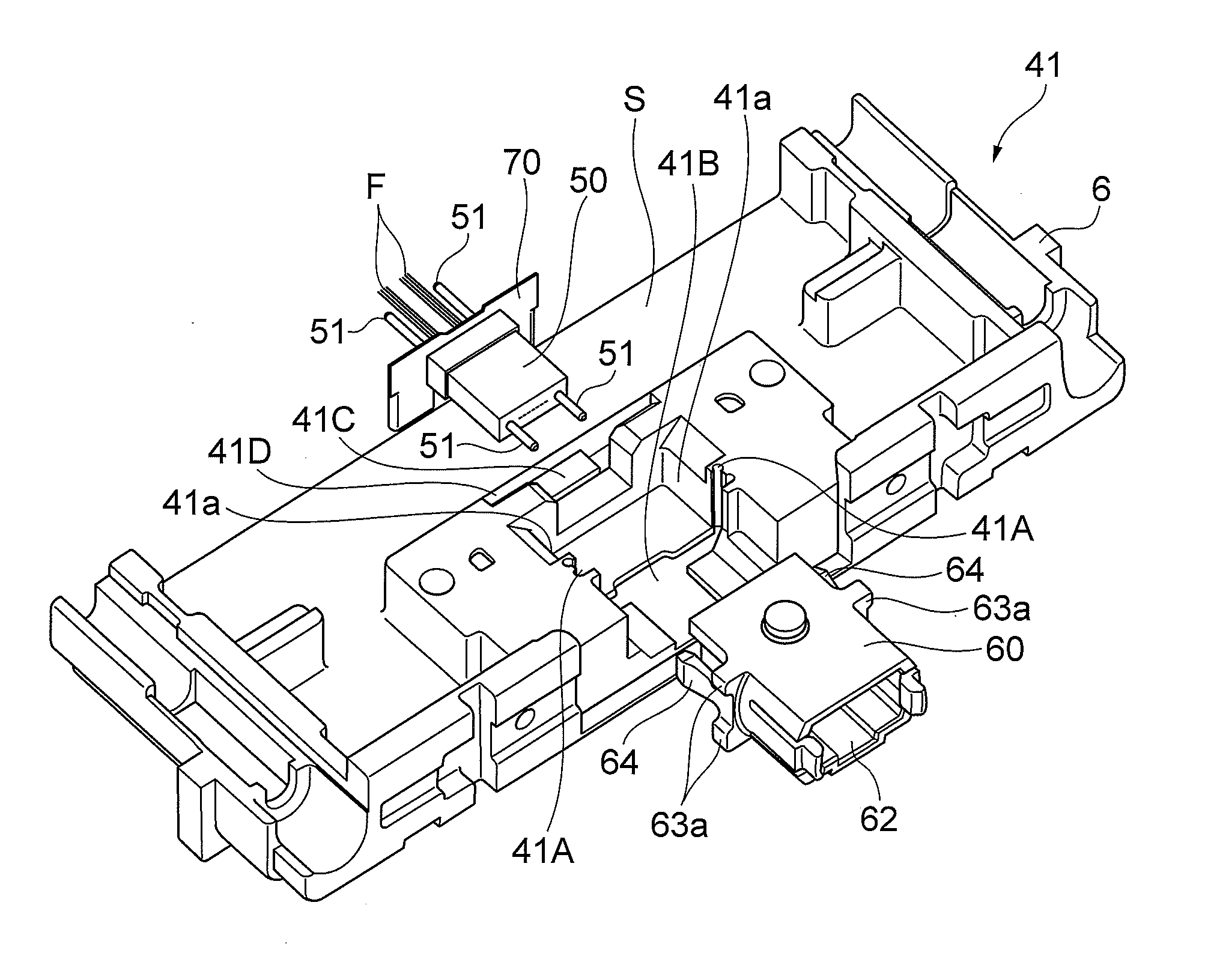

[0051]The receptacle portion 141 of the present embodiment shown in FIGS. 13 and 14, removes the terrace 41C. Instead of the terrace 41C, the receptacle portion 141 provides a hollow 141D to receive the mechanism 170 therein. The mechanism 170 includes a holder 171 with a rectangular shape to hold the MT ferrule 50 and a spring 172 to push the holder 171 against the MT ferrule 50. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com