Cooling device for a condenser of a system for a thermodynamic cycle, system for a thermodynamic cycle, arrangement with an internal combustion engine and a system, vehicle, and a method for carrying out a thermodynamic cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

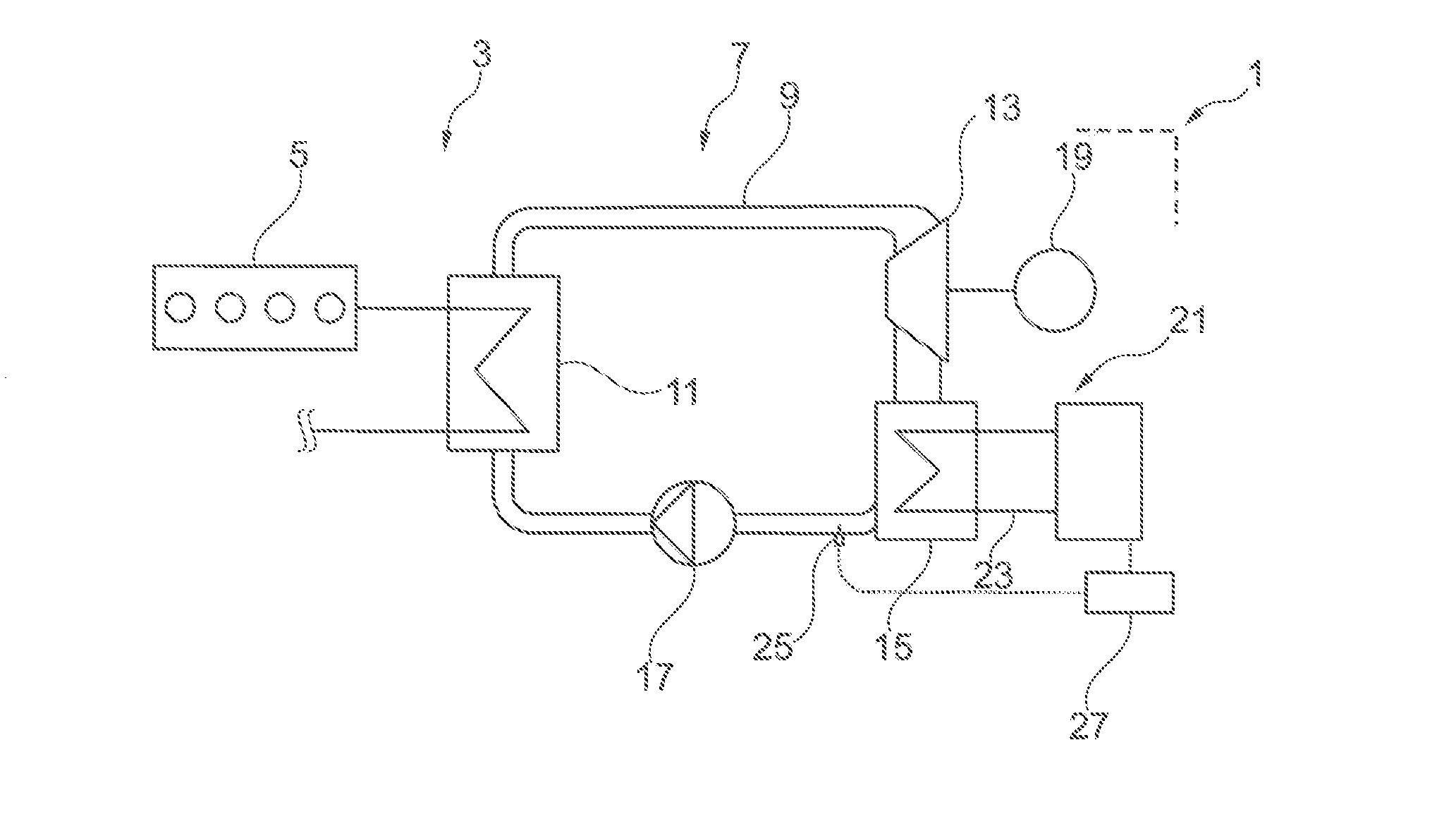

[0037]FIG. 1 shows a schematic diagram of an exemplary embodiment of a motor-driven vehicle 1, which comprises an arrangement 3 consisting of an internal combustion engine 5 and a system 7 for operating a thermodynamic cycle, here in particular an organic Rankine cycle (ORC). The motor-driven vehicle 1 is preferably configured as a ship. Alternatively, however, an embodiment of the motor-driven vehicle 1 as a rail vehicle, as a mining or construction vehicle, as a defensive vehicle, as a truck, or even as a passenger vehicle is also possible.

[0038]The use of the arrangement 3 is not limited to motor-driven vehicles; instead, it can be used in other areas as well, including stationary uses of the internal combustion engine 5 to operate pumps on an offshore drilling rig, for example, where the waste heat of the engine can be put to positive use.

[0039]Finally, the system 7 is not limited to use in an arrangement with an internal combustion engine 5. On the contrary, it can be used in o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com