Sheet feeding apparatus and image forming apparatus

a feeding apparatus and a technology of forming apparatus, applied in the direction of transportation and packaging, thin material processing, article separation, etc., can solve the problems of reducing separation performance and more strictly managing the position accuracy of the return roller, so as to prevent the overlapping of sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

Image Forming Apparatus

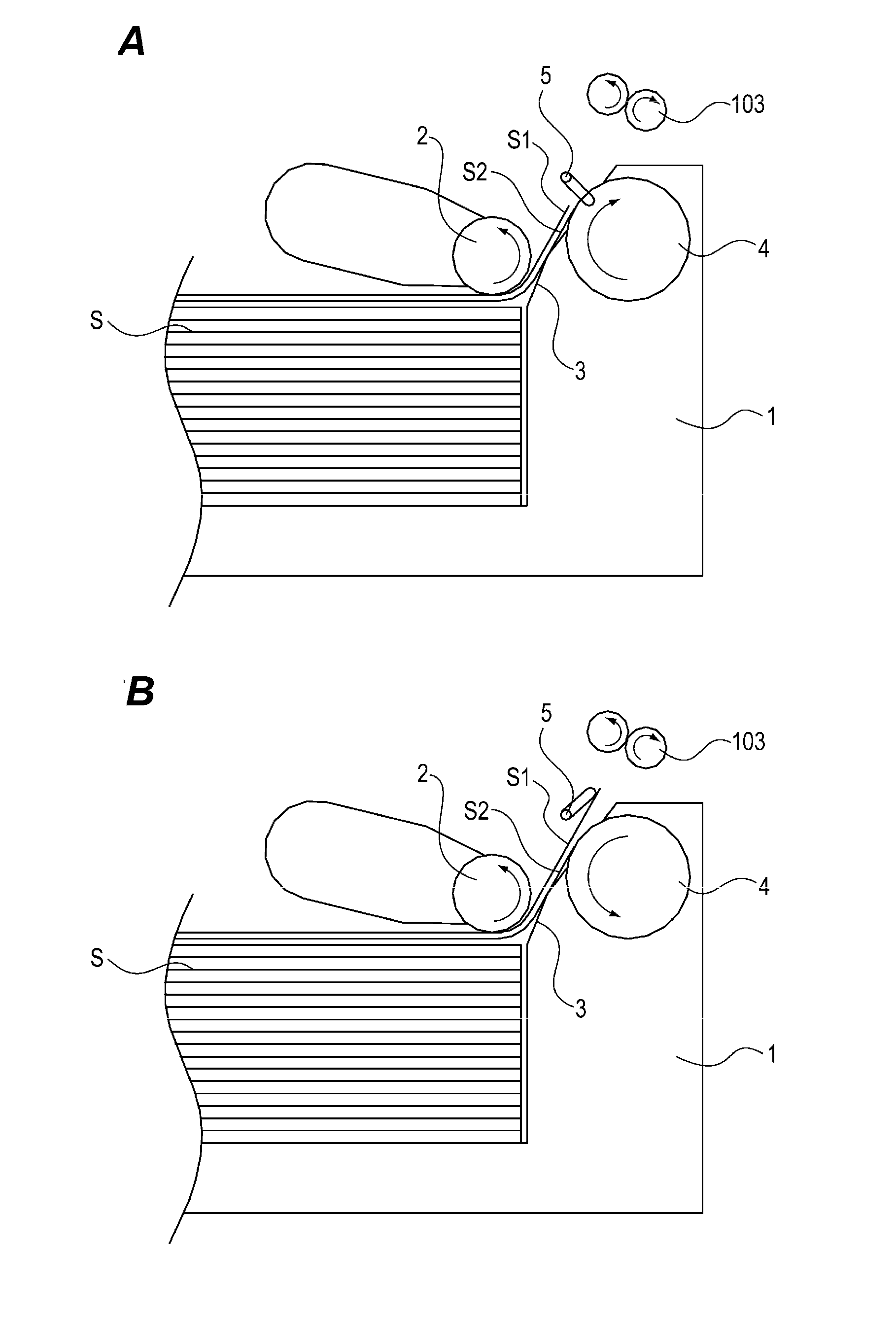

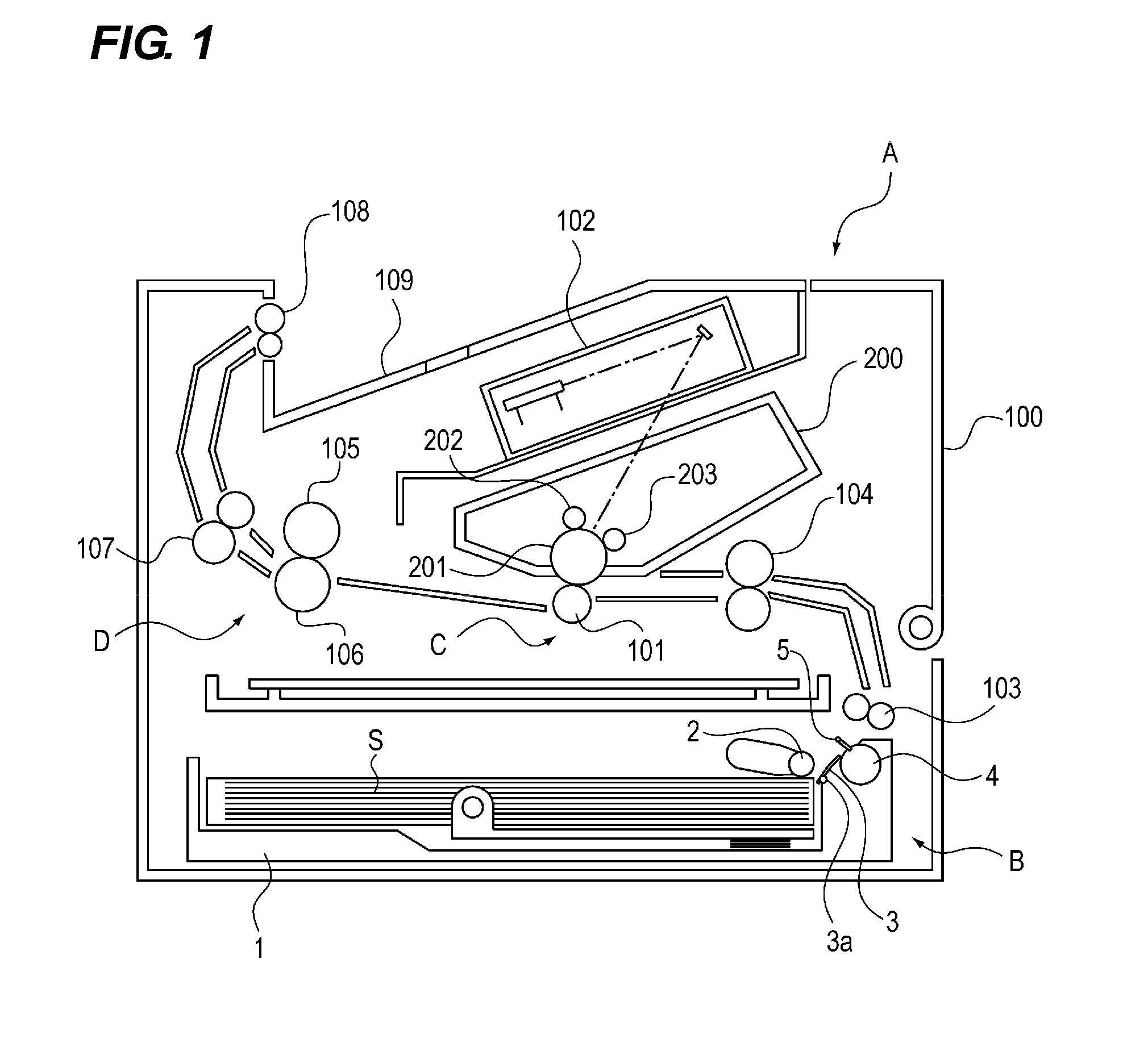

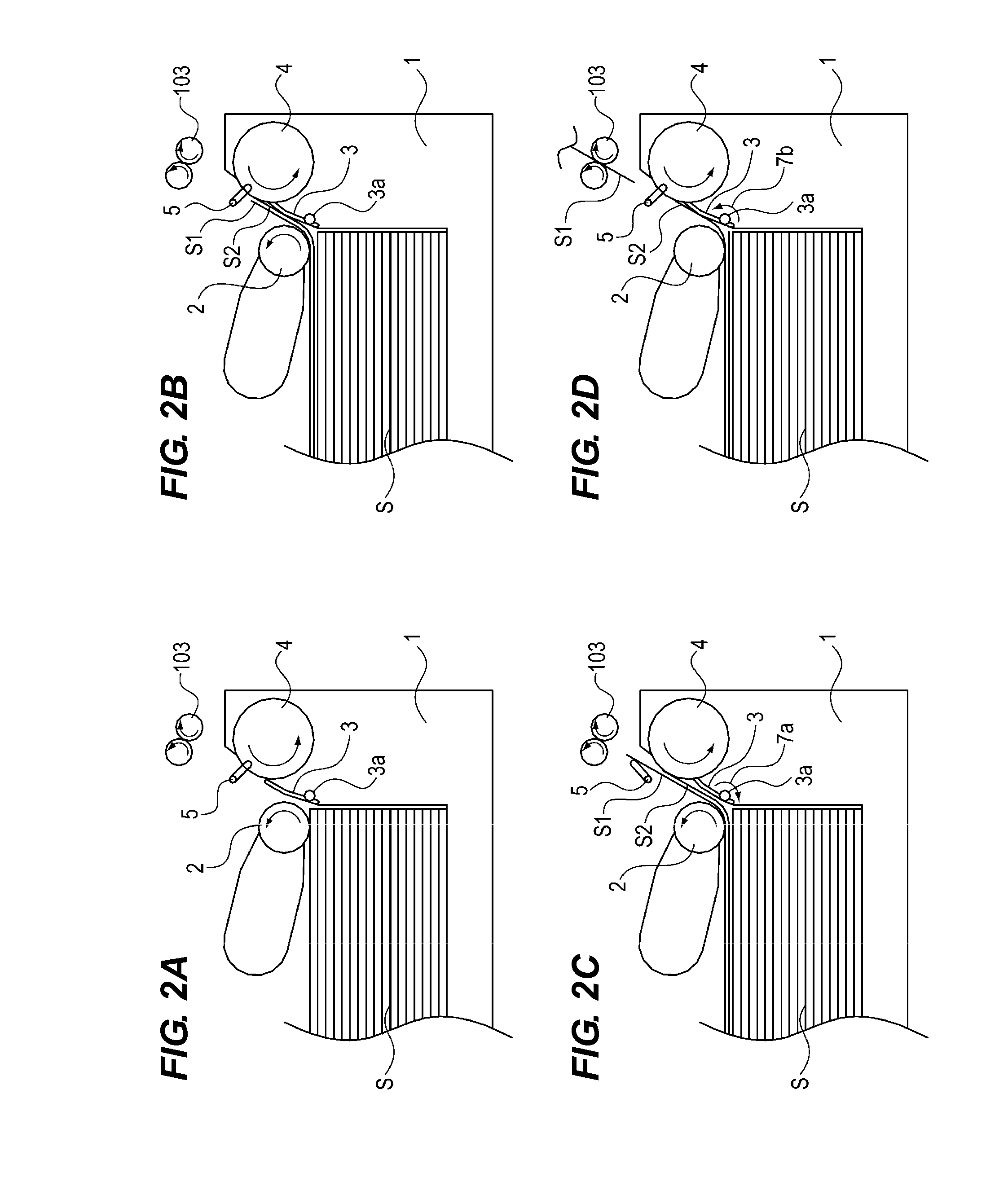

[0023]An entire configuration of an image forming apparatus which includes a sheet feeding apparatus according to a first embodiment of the present invention will be described with reference to FIG. 1.

[0024]FIG. 1 is a schematic cross-sectional view of the image forming apparatus. An image forming apparatus A includes, when it is roughly divided, a sheet feeding apparatus B which feeds a sheet S from a stacking portion, and an image forming portion which forms a toner image on the fed sheet S. Then, the image forming portion includes an image transfer portion C which transfers the toner image onto the sheet and a fixing device D which fixes the toner image to the sheet.

[0025]The image transfer portion C includes a cartridge 200 which is detachably attachable to an image forming apparatus body 100, a transfer roller 101, and a laser scanner unit 102. The cartridge 200 includes a photosensitive drum 201, a charging device 202, and a development device 203.

[0026]...

second embodiment

[0045]Next, an apparatus according to a second embodiment will be described with reference to FIGS. 6A and 6B. Note that, since the basic configurations of the apparatus in the present embodiment are same as those of the above-described embodiment, the redundant descriptions will be omitted, and the members having the same functions as those of the above-described embodiment will be denoted by the same reference numerals.

[0046]A surface of a return roller 4 is made of a rubber material having a relatively high frictional resistance. For this reason, when a leading end of a sheet fed by a feeding roller 2 butts against the return roller 4 rotating in a direction to return the sheet, there is a possibility that the folding of the leading end of the sheet, and the like occur (see FIG. 9D).

[0047]Thus, in the present embodiment, there is provided a rotation switching mechanism which switches a rotation direction of the return roller 4. Then, the return roller 4 is rotated in a direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com