Apparatuses and Methods for Adjusting the Temperature Inside a Helmet

a technology for helmets and apparatuses, applied in the field of helmets, can solve problems such as brain damage, death or life-long disability, and helmets can pose their own unique problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 100

[0025]FIG. 1 depicts an embodiment 100 of the present helmets. Helmet 100 may be any type of helmet configured to be worn by a user, including, but not limited to, a sports helmet (e.g., helmets for football, in-line skating, skate boarding, snowboarding, skiing, and / or biking), a motorsports helmet (e.g., helmets for on-road racing, off-road racing, for use with all-terrain vehicles (ATVs), dirt bikes, and / or four wheelers), a construction helmet (e.g., hard hats), and / or the like. Helmet 100 comprises a thermoelectric element 101 (described in more detail below) having at least one heating surface (e.g., 101a) and at least one cooling surface (e.g., 101b). Helmet 100 further comprises a thermally conductive cloth 102 (described in more detail below) disposed within the helmet and selectively coupled to either heating surface 101a or cooling surface 101b such that the cloth is in thermal communication (e.g., as indicated by arrow 103) with the thermoelectric element. In this embodi...

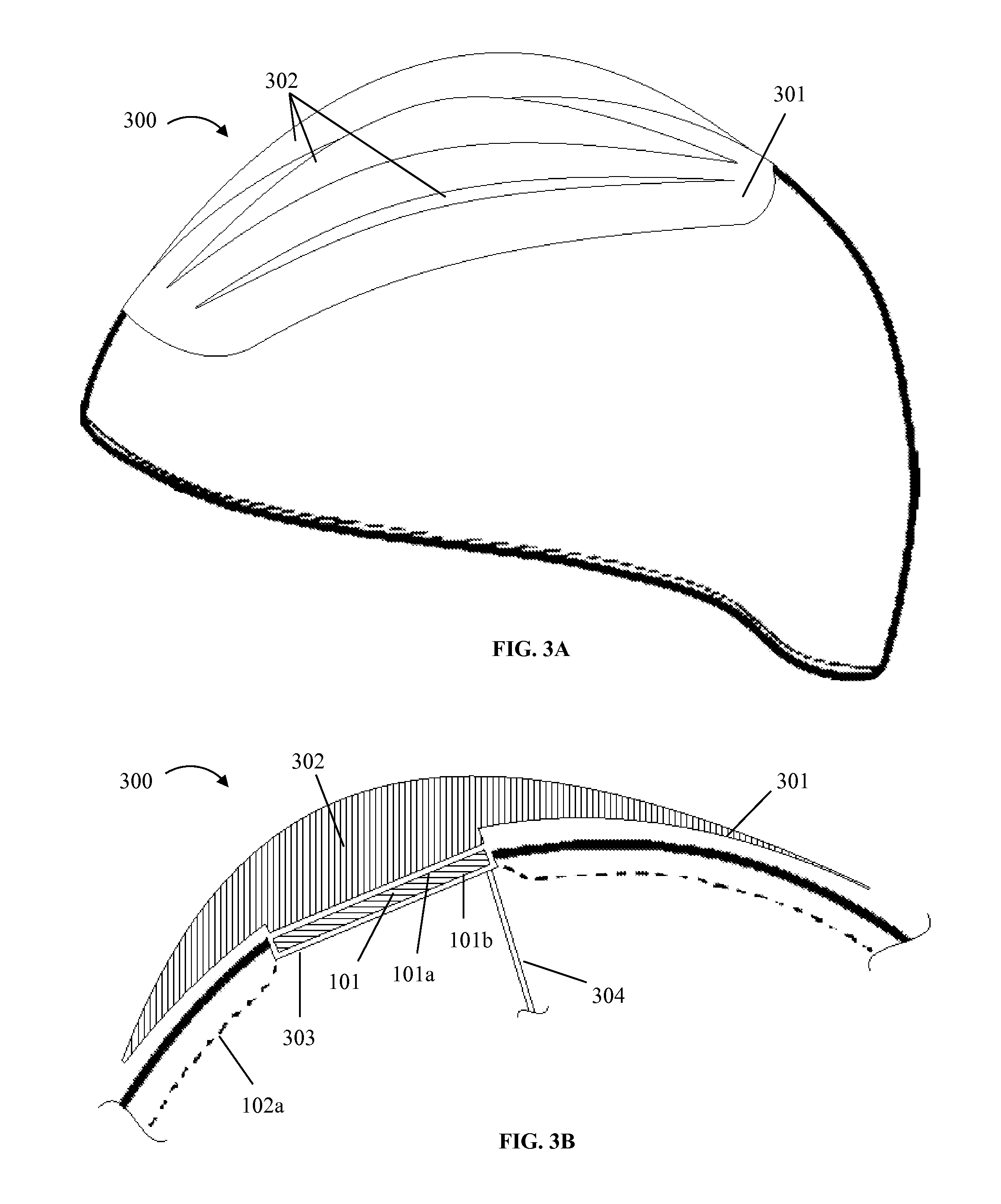

embodiment 300

[0029]FIG. 3A depicts another embodiment 300 of the present helmets. Helmet 300 is substantially similar to helmet 100, with the primary exception that an external surface 301 of helmet 300 comprises a plurality of thermally conductive fins 302. Thermally conductive fins 302 may be constructed from a variety of thermally conductive materials, including, but not limited to, carbon fiber, copper, silver, silicon, and / or aluminum. In the embodiment shown, thermally conductive fins are elongated (e.g., having a maximum longitudinal dimension of approximately 70% of a largest corresponding dimension of the helmet), thin, and substantially flat (e.g., having a thickness or transverse dimension of no greater than 5 millimeters (mm)). In this embodiment, thermally conductive fins 302 comprise a small cross-sectional shape when viewed from the front of helmet 300 and thus are capable of transferring a substantial amount of heat to the environment (e.g., through the sides of the fins), withou...

embodiment 400

[0031]FIG. 4 depicts another embodiment 400 of the present helmets. Helmet 400 is substantially similar to helmet 100, with the primary exception that helmet 400 comprises a control circuit 401 in electrical communication with thermoelectric element 101 and power source 104 (e.g., such that control circuit 401 can control the voltage and / or current supplied to thermoelectric element 101 from power source 104). In some embodiments, control circuit 401 comprises a thermostat configured to adjust a temperature inside of the helmet, for example, a bi-metallic strip thermostat. Bi-metallic strip thermostats can comprise two thin strips, each comprising a different type of metal. When the temperature of and / or within the thermostat changes, the differential thermal expansion of the two strips causes the strips to move relative to one another, which can be used to break or complete a circuit (e.g., similar to an on-off switch). Embodiments of the present helmets with control circuits (e.g....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com