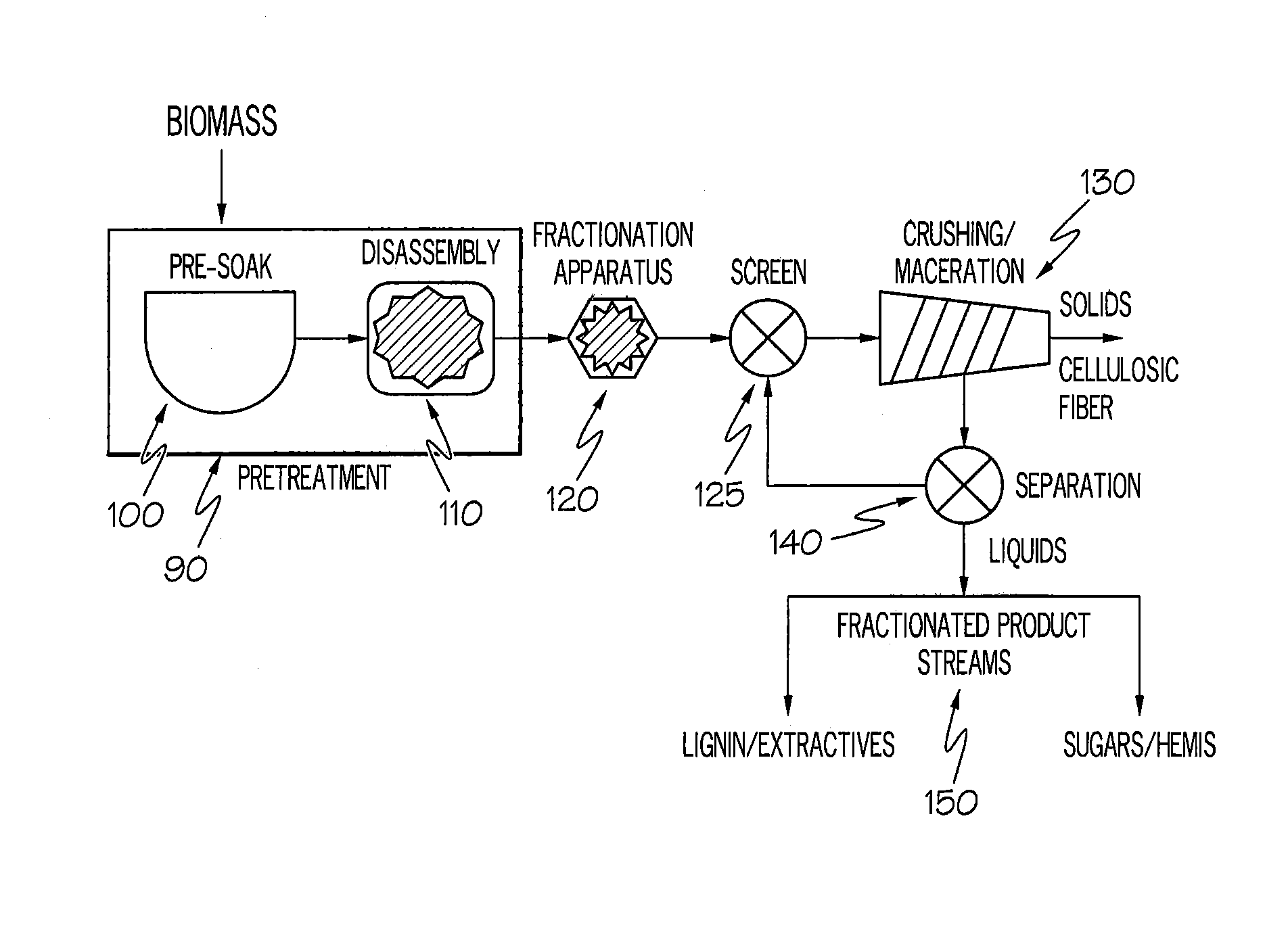

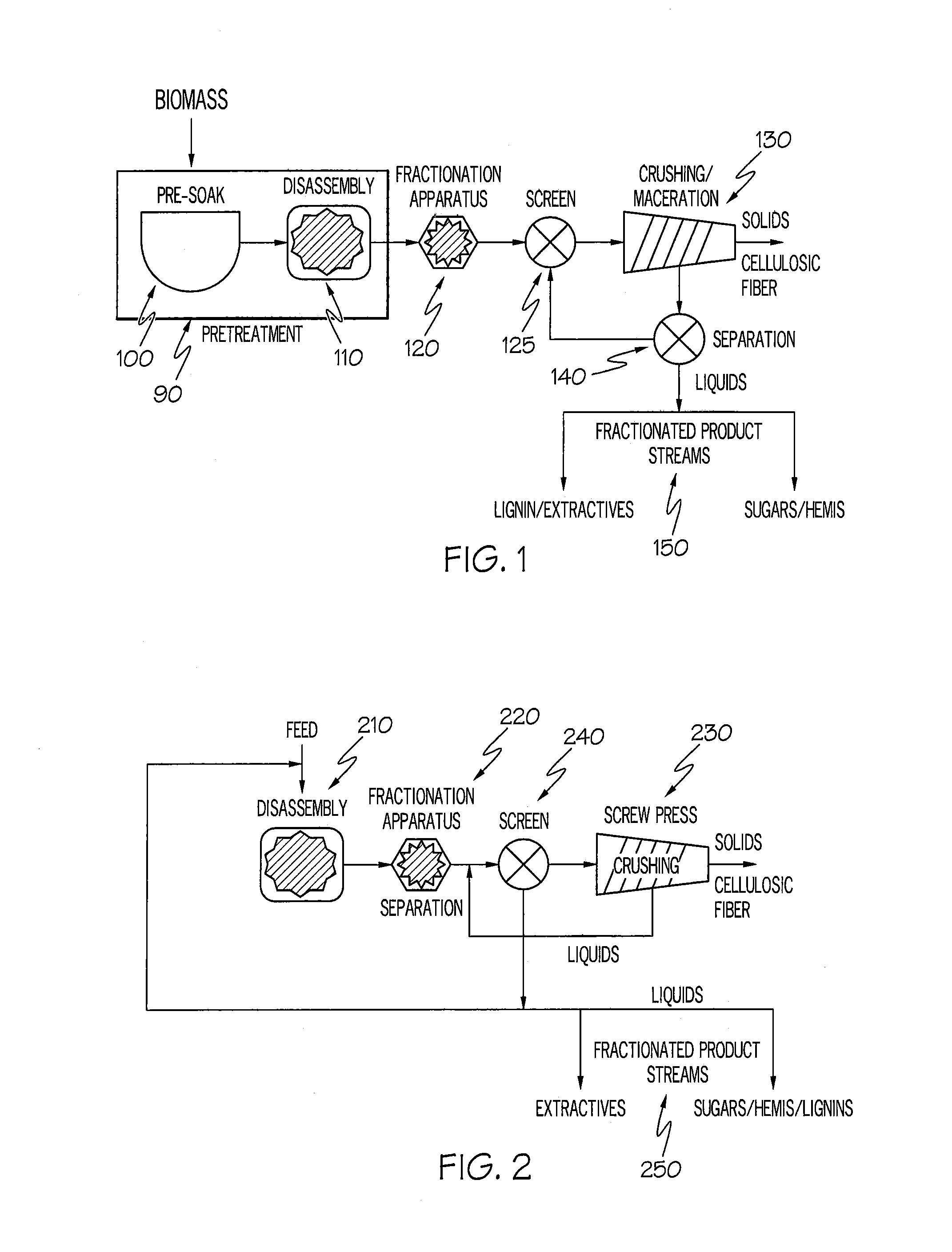

Method for isolating cellulose from a biomass and products provided therefrom

a technology of biomass and isolating components, which is applied in the field of isolating components of biomass, can solve problems such as problems such as problems in using cellulose as a feedstock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Wheat Grass

[0060]10 Kg of dried wheat grass (straw) is chopped to a stalk length of ¾ to 2 inches. The straw was briefly rinsed with cold clean water to remove sand and dirt. The wheat straw is then subjected to water or steam injection into a disk mill for a few seconds to mechanically disassemble the cellulosic structure. The fluidized wheat grass is then subjected to high shear forces for 1.5 to 3 seconds with pulses of 1824 to 912 times without denaturing and / or degrading the components of the wheat straw. The combined mixture is subjected to compressive forces to separate the stream into liquid and a 20-60% cellulosic solids fractions. The liquid fraction containing hemicellulose is retained.

[0061]The solid fraction is pretreated with NaOH sufficient to raise the pH of the cellulosic water slurry from about 4-7 to 10-12. This basic mixture is allowed to age from a few seconds to 1 hour and again processed through the system starting at the disk mill which is subjected to water ...

example 2

[0063]423 grams of dry switch grass is steam activated to rehydrate at about 25 to 50 percent water in a single disk refiner to provide the switch grass in a fluidized or flowable condition. Naturally occurring carboxylic acids (acetic acid and formic acid) with the switch grass lower the pH to below 3. The hydrated / activated switch grass is subjected to compressive force to separate a liquid high in hemicelluloses and a biomass high in cellulose and lignin. The hemicellulose / liquid is then subjected to a 1 to 5 kD ultrafiltration membrane to remove the acetic acid and formic acid as a permeate for reuse in the process.

[0064]The biomass is then subjected to high frequency pulses and shear forces without denaturing and / or degrading the lignin using the Green Extraction Technology fractionation apparatus described in U.S. application Ser. No. 14 / 454,833 filed on Aug. 8, 2014. The biomass is fractionated for about 15 to about 30 seconds at pulses of 912 to 1824 to provide a first fract...

example 3

[0067]423 grams of dry wheat straw is steam activated to rehydrate at about 25 to 50 percent water in a single disk refiner to provide the switch grass in a fluidized or flowable condition. Naturally occurring carboxylic acids (acetic acid and formic acid) within the wheat straw lower the pH to below 3. The hydrated / activated wheat straw is subjected to compressive force to separate a liquid high in hemicelluloses and a biomass high in cellulose and lignin. The hemicellulose / liquid is then subjected to a 1 to 5 kD ultrafiltration membrane to remove the acetic acid and formic acid as a permeate for reuse in the process.

[0068]The biomass is then subjected to high frequency pulses and shear forces without denaturing and / or degrading the lignin using the Green Extraction Technology fractionation apparatus described in U.S. application Ser. No. 14 / 454,833 filed on Aug. 8, 2014. The biomass is fractionated for about 15 to about 30 seconds at pulses of 912 to 1824 to provide a first fracti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| v/v | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com