Connector system and building components for use in building construction

a technology for connecting systems and building components, applied in the direction of connecting rods, controlling members, building components, etc., can solve the problems of difficulty and cost of transportation, legal or practical size limitations may still need to be observed, and it is impossible to transport an entire house from a factory in view

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 300

[0096]FIGS. 32-35 illustrate an alternative connector system embodiment 300. FIGS. 32 and 33 illustrate a male connector 302 of system 300 and corresponding female connector 352 of system 300, respectively, both in perspective view. FIG. 34 illustrates the male and female connectors 302, 352 after having been mated. FIG. 35 illustrates the mated connectors 302 and 352 attached to respective framing members 400 and 402.

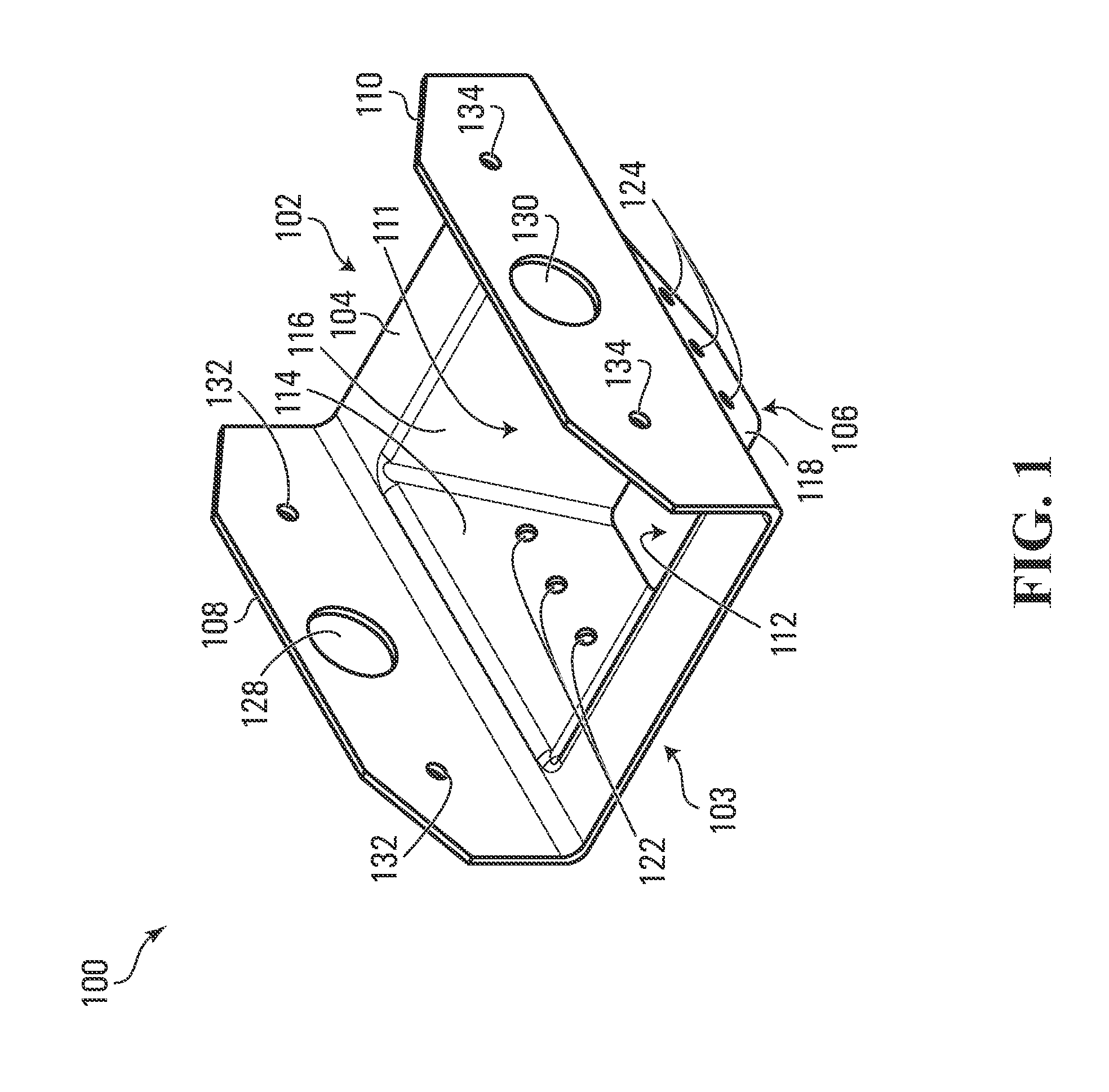

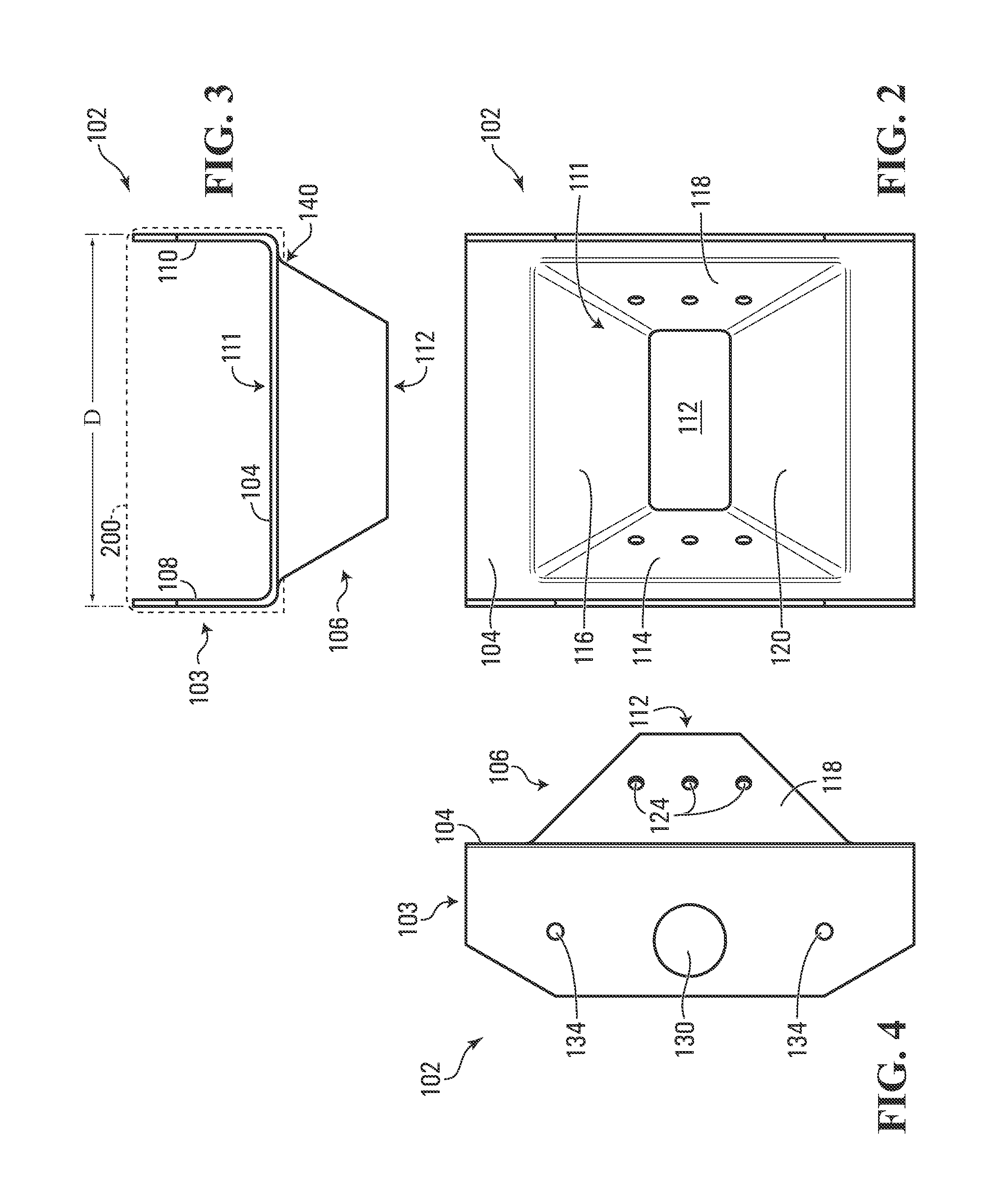

[0097]Referring FIG. 32, it can be seen that the connector body 303 of example male connector 302 is similar to that of earlier described male connector 102. That is, connector body 303 comprises a plate 304 and flanges 308 and 310 extending upwardly on opposite sides of the plate 104. As well, connector body 303 has a hollow tapered protrusion 306 protruding downwardly therefrom. However, the three-dimensional shape of the tapered protrusion 306 in this embodiment is different from that of tapered protrusion 106 of the earlier discussed embodiment. In particular, two ...

embodiment 800

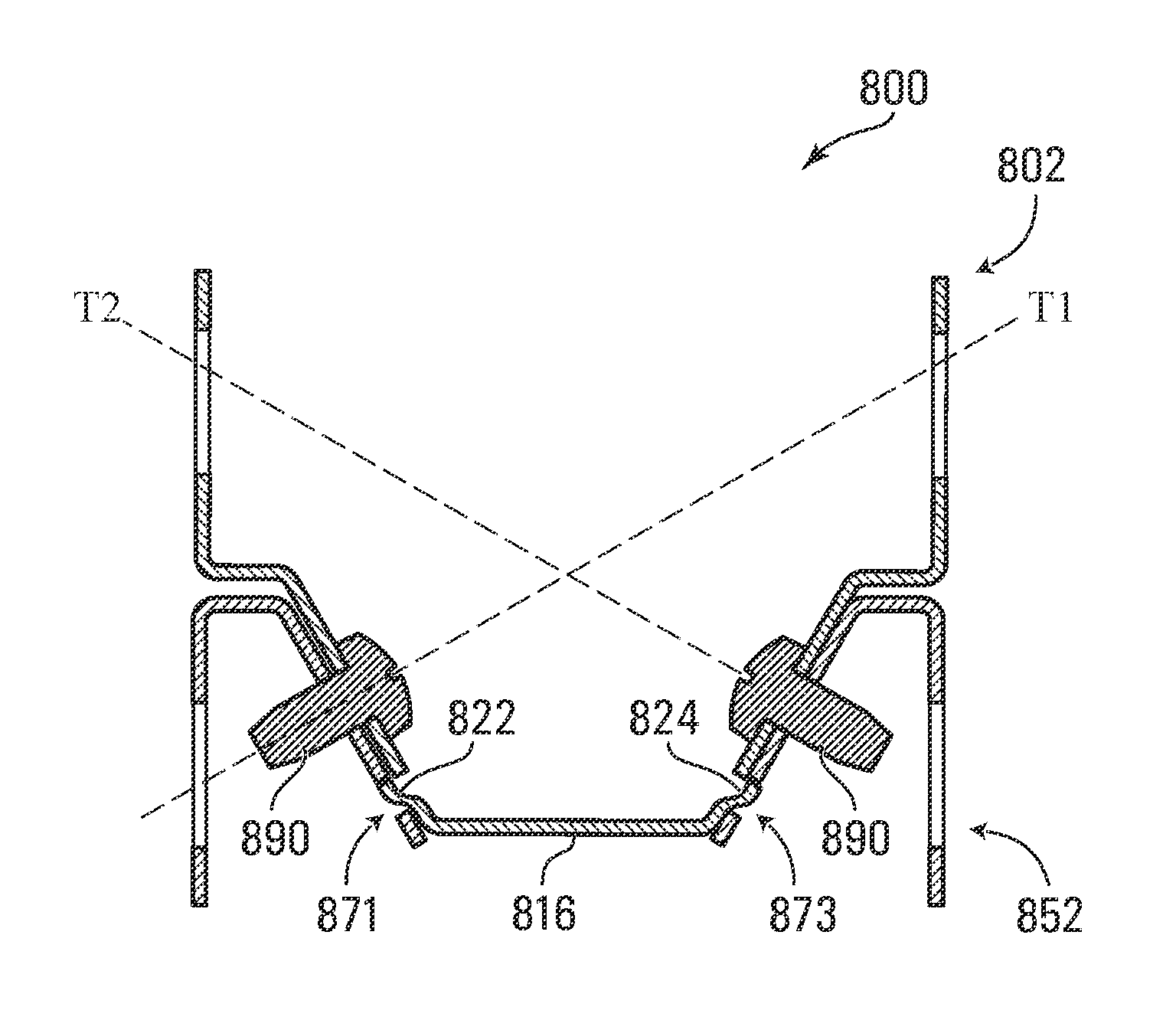

[0128]Referring to FIGS. 49-62, a further embodiment 800 of a connector system is illustrated. The connector system 800, which may be referred to as a locking or snap-fit connector system 800, includes a male connector 802 and a female connector 852. As will become apparent, this connector system 800 differs from the connector system 100 described above, primarily in that the male and female connectors collectively define a snap-fit for joining the male connector 802 with the female connector 852 upon mating of the two and in that manufacture of the male connector and / or the female connector may be simplified.

[0129]The male connector 802 is illustrated in FIGS. 49-53, in perspective view, plan view, front view, side view and cross sectional view, respectively. The male connector 802 may be formed from a single piece of sheet metal (e.g. progressive stamped sheet metal) or another rigid material.

[0130]The exemplary male connector 802 comprises a connector body 803 and a tapered protr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com