Velcro Abrasive Cloth

a velcro-backed abrasive cloth and velcro-backed technology, applied in the direction of abrasive equipment, metal-working equipment, manufacturing tools, etc., can solve the problems of shortening the product life, weak paper, and complicated process, and achieves low cost, high efficiency, and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]In the following the invention will be described in greater detail with reference to the attached drawings.

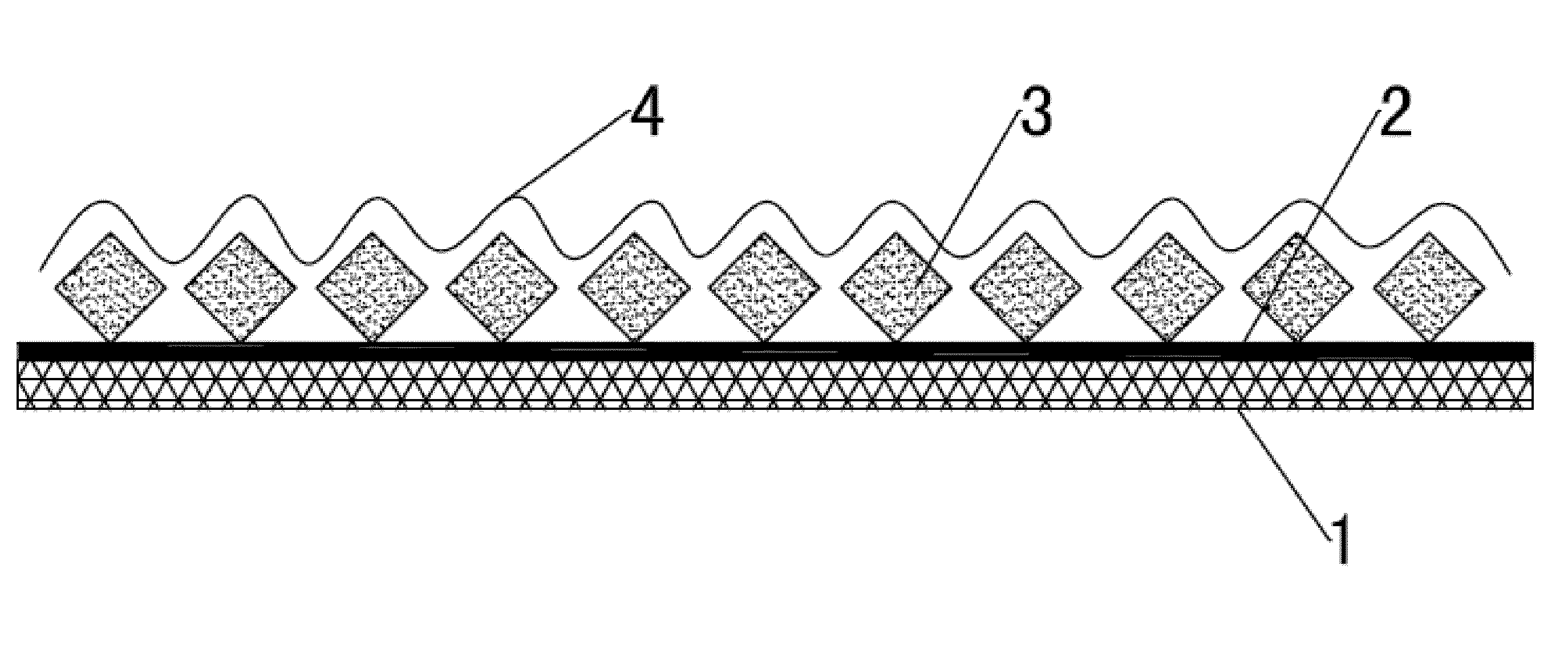

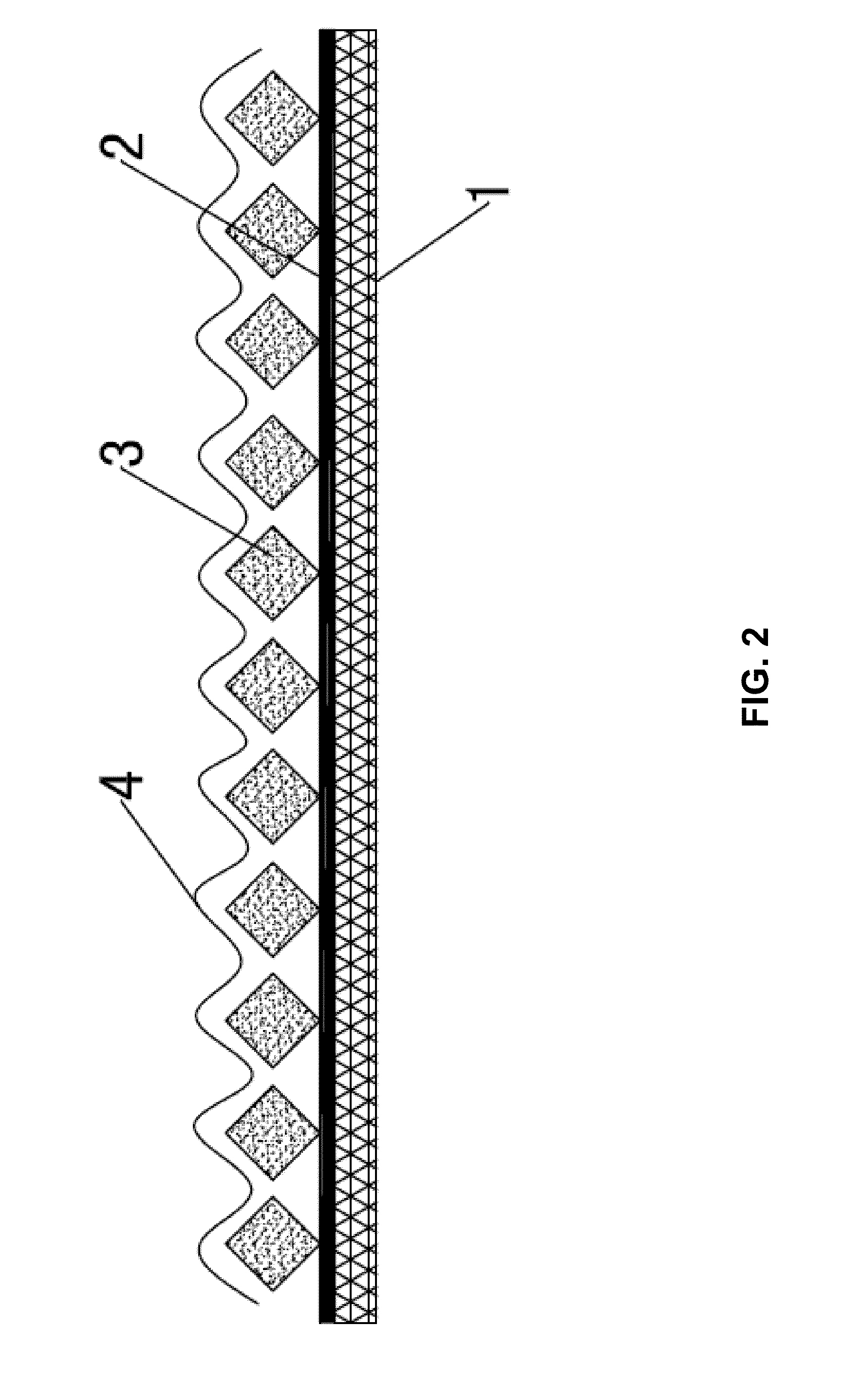

[0022]Refer to FIGS. 1 and 2, the Velcro-backed abrasive cloth comprises a base material (1); the base material is a napped cloth with Velcro on one side. The Velcro is created by a roller raising machine and immersed in one of or a combination of the following solutions: phenolic resin, latex, polyvinyl alcohol, amylum, epoxy resin, ethylene-vinyl acetate copolymer.

[0023]The side with no Velcro is then coated with a layer of primer (2) and an abrasive layer (3) is formed on top of the primer. A multi-layer adhesive (4) is then coated on top of the abrasive layer. The multi-layer adhesive has either an anti-clogging or anti-static coating or a combination of both. The adhesive binders of the primer and multi-layer adhesive can be made from one or a combination of the following: phenolic resins, epoxy resins, urea-formaldehyde, polyvinyl alcohols, and latexes. The abrasive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com