Control system for monitoring and adjusting combustion performance in a cordwood-fired heating appliance

a control system and heating appliance technology, applied in the direction of heating types, ways, stoves or ranges, etc., can solve the problems of not reflecting real world conditions, excessive emissions, and difficulty in obtaining a low emission profile during the operation of a wood burning appliance, so as to reduce emissions, improve efficiency, and reduce emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

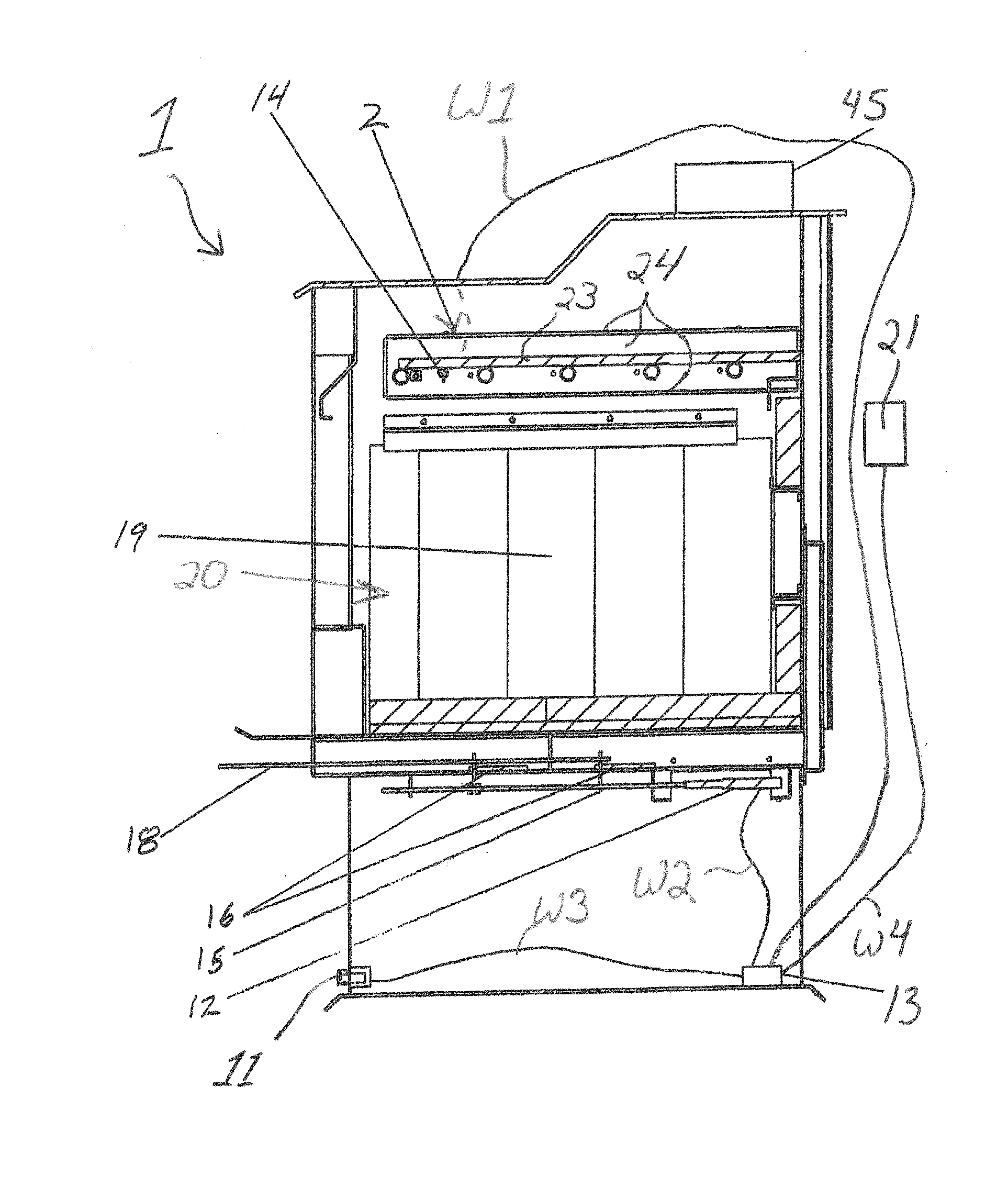

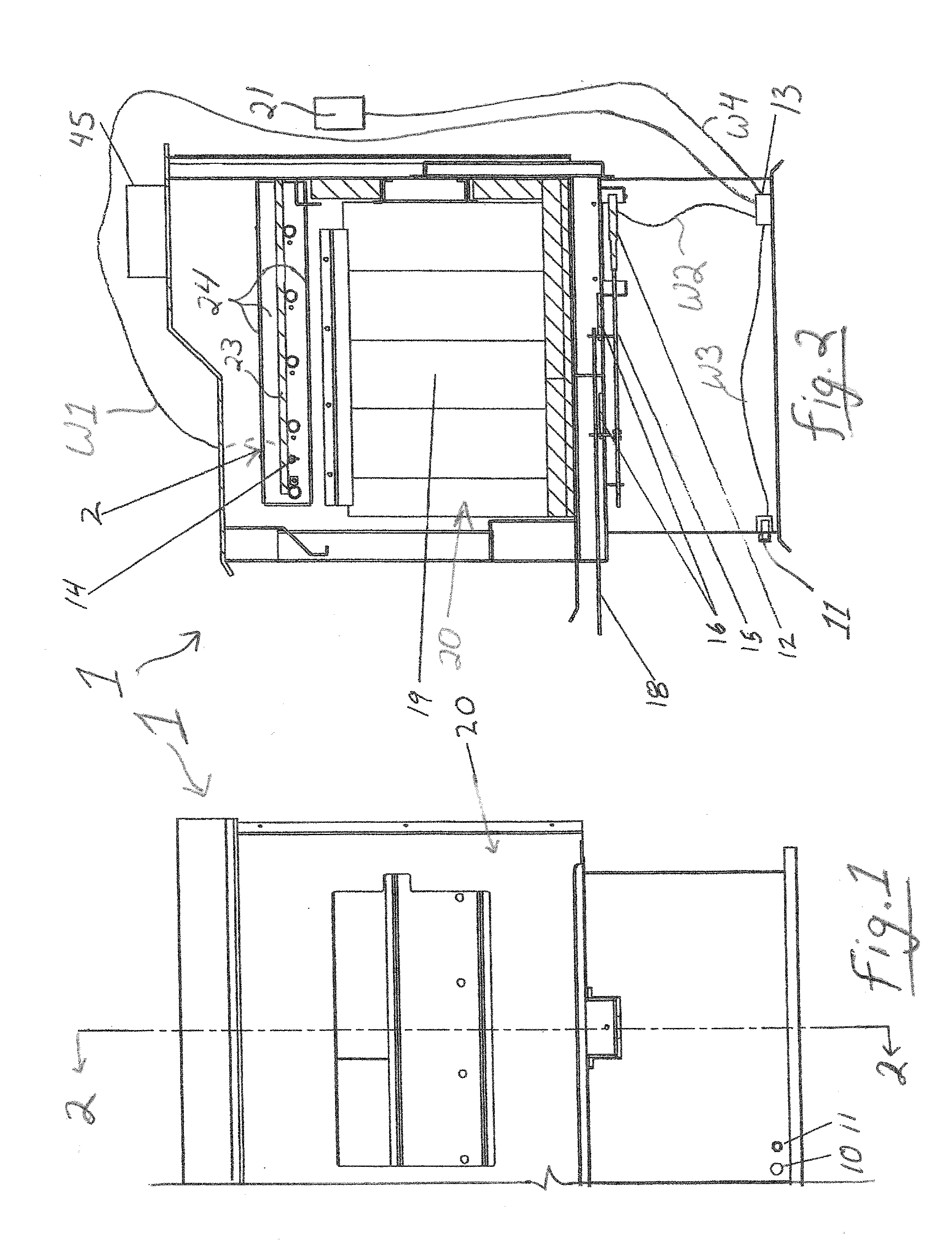

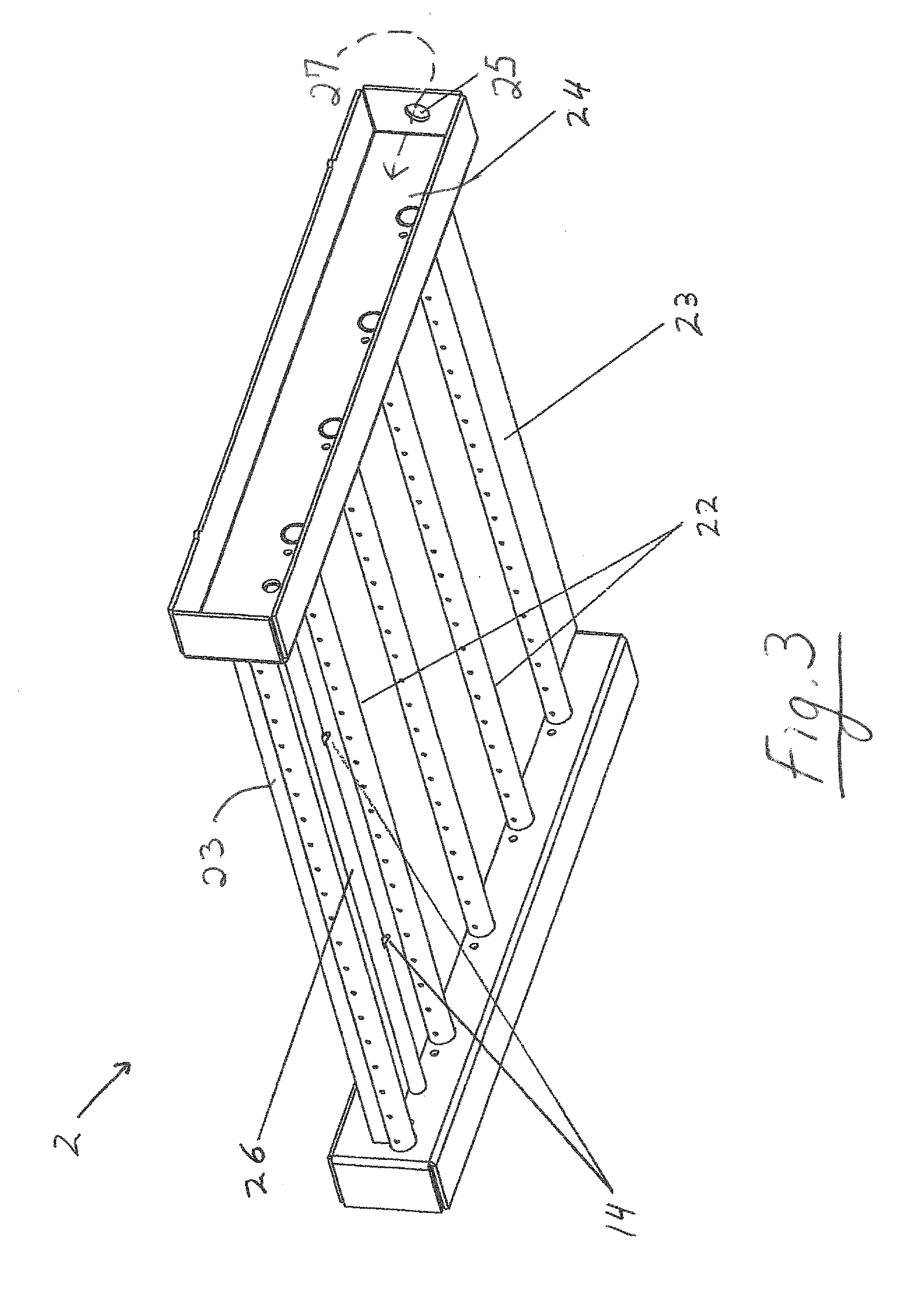

[0029]Conventional appliances comprise a primary combustion chamber (also “main combustion chamber”, “main firebox”, or “firebox”) for receiving the wood or other solid fuel during the combustion event. The main firebox is an insulated volume, where the solid-fuel / wood resides, that has air passage openings that deliver primary air to one or more specific areas of the main firebox mainly for combustion of the solid fuel. The appliance is typically air-tight except for the primary air and secondary air inlets into the primary and secondary combustion zones. Typically, a variable orifice / valve controls the flow of primary air to the various passage openings to the main firebox. The variable orifice / valve may be comprised of a generally tight sealing valve, for example, a sliding plate orifice system or rotating valve allowing various amounts of air to enter the main firebox. An electronic actuator is typically attached to this orifice, allowing for full-open or full-closed positions a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com