Socket-projection fixing assembly

a technology of sockets and fixing parts, applied in the direction of wind energy generation, structural elements, building components, etc., can solve the problems of smallest possible number of additional operations and the least possible extent of extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045]In the figures the same or similar parts are denoted by the same reference numeral.

[0046]FIG. 1 shows a wind turbine tower 1 which has four successive cylindrical concrete prefabricated sections 2, 2′, 2″, 2′″. A respective horizontal wet joint 3, 3′, 3″ is formed between each couple of successive sections, which joint comprises a respective socket-projection fixing assembly according to the invention, i.e. said tower includes three horizontal wet joints 3, 3′, 3″ and three socket-projection fixing assemblies according to the invention (said socket-projection fixing assemblies according to the invention not shown in FIG. 1).

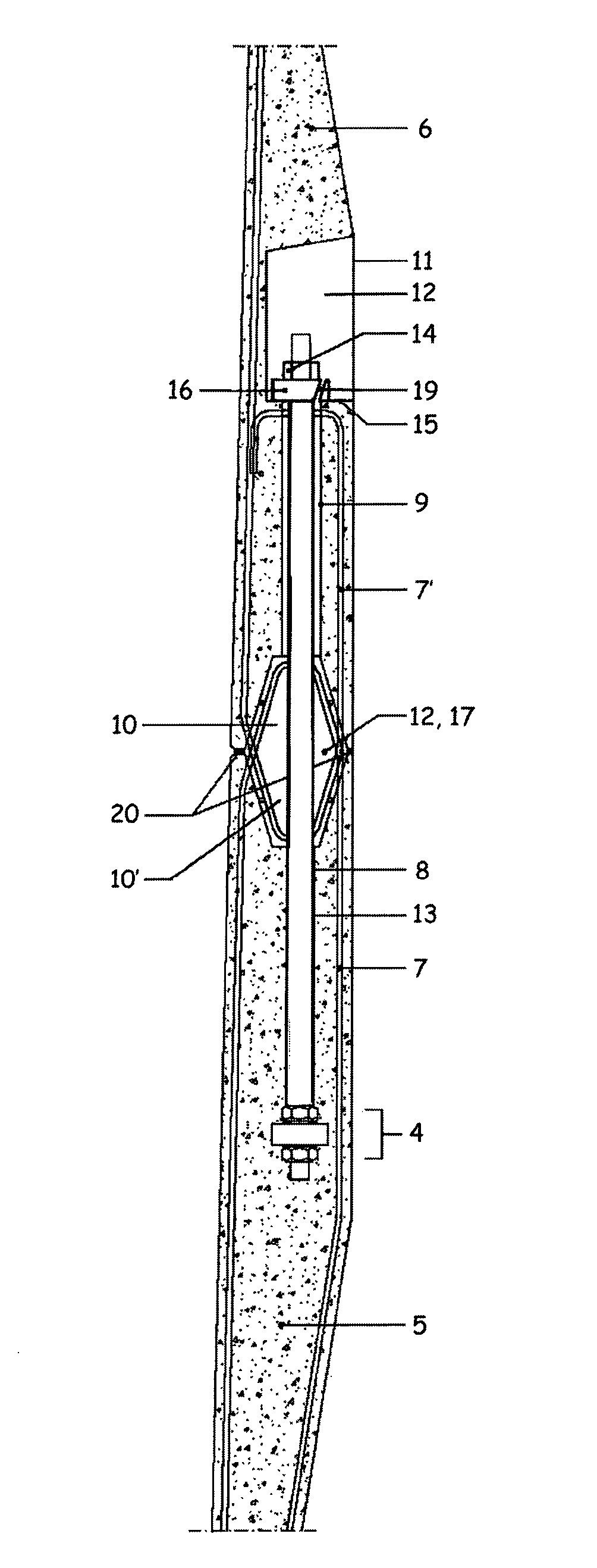

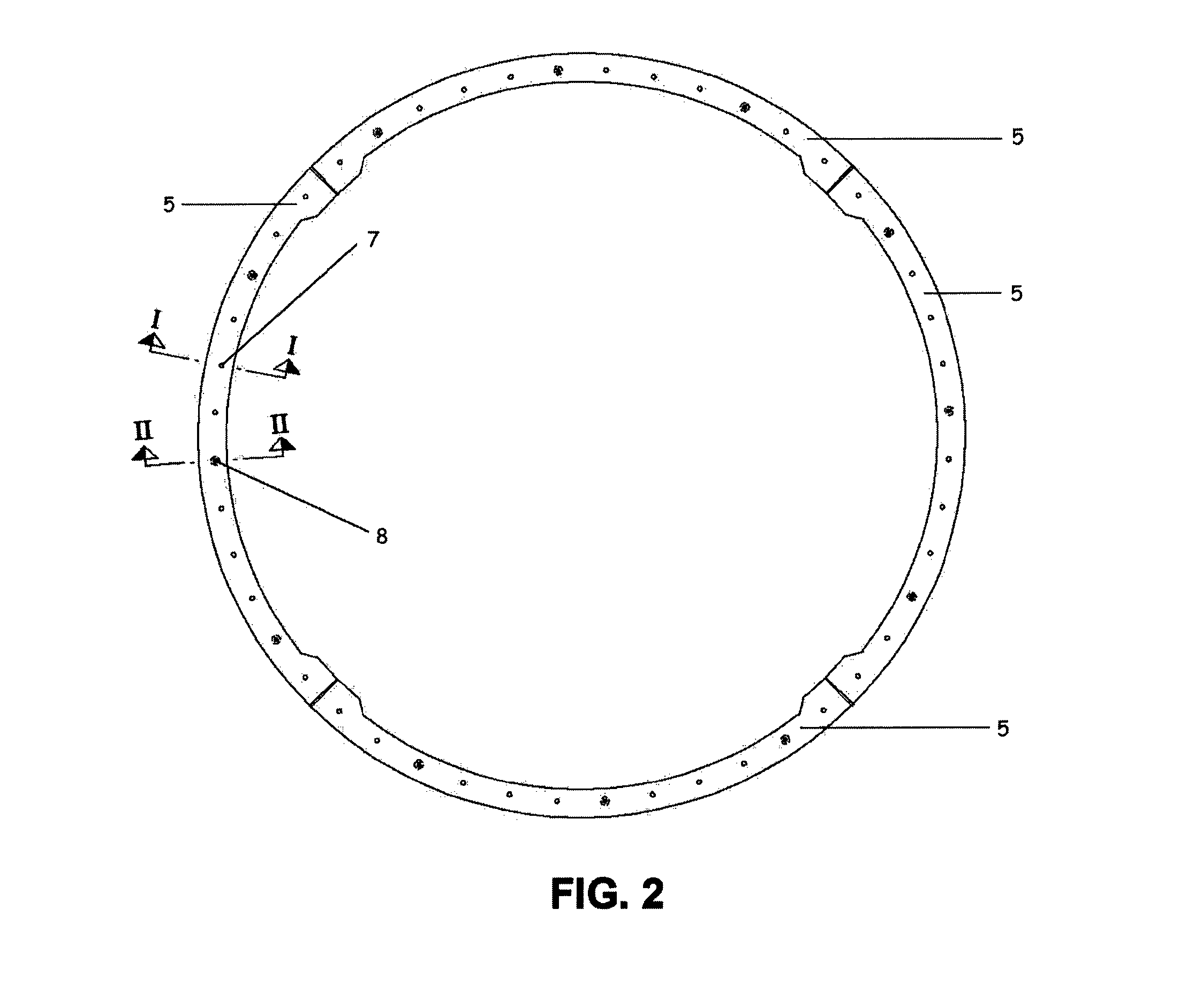

[0047]FIG. 2 shows a cross-sectional view of said tower 1 in correspondence with the lower horizontal wet joint 3 between a lower section 2 and an upper section 2′, to illustrate the respective socket-projection fixing assembly according to the invention and lower section 2. Said socket-projection fixing assembly according to the invention of said lower hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com