Heat pump apparatus and method of controlling heat pump apparatus

a heat pump and heat pump technology, applied in the direction of lighting and heating apparatus, heating types, refrigeration components, etc., can solve the problem of all these refrigerants being flammabl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

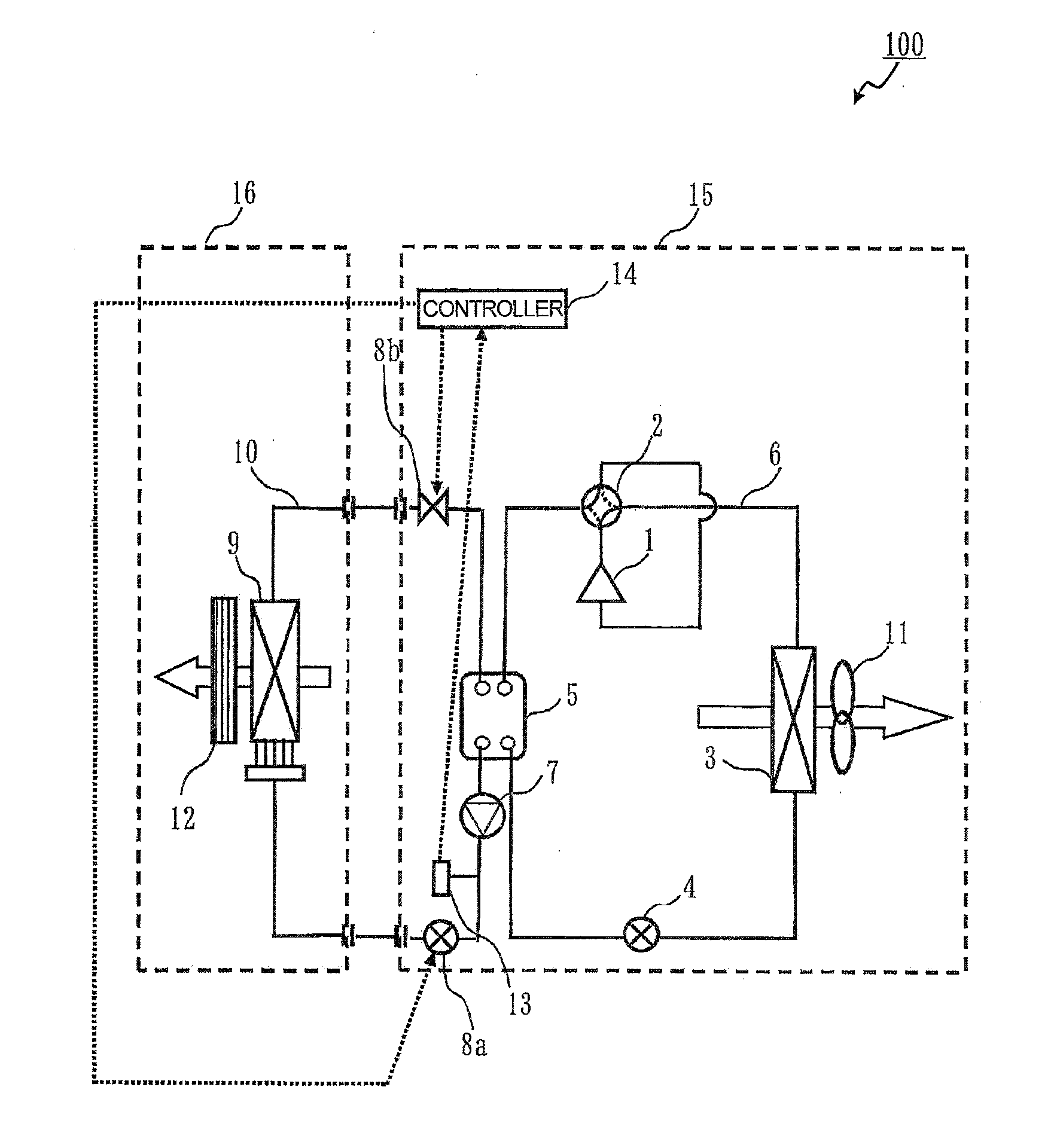

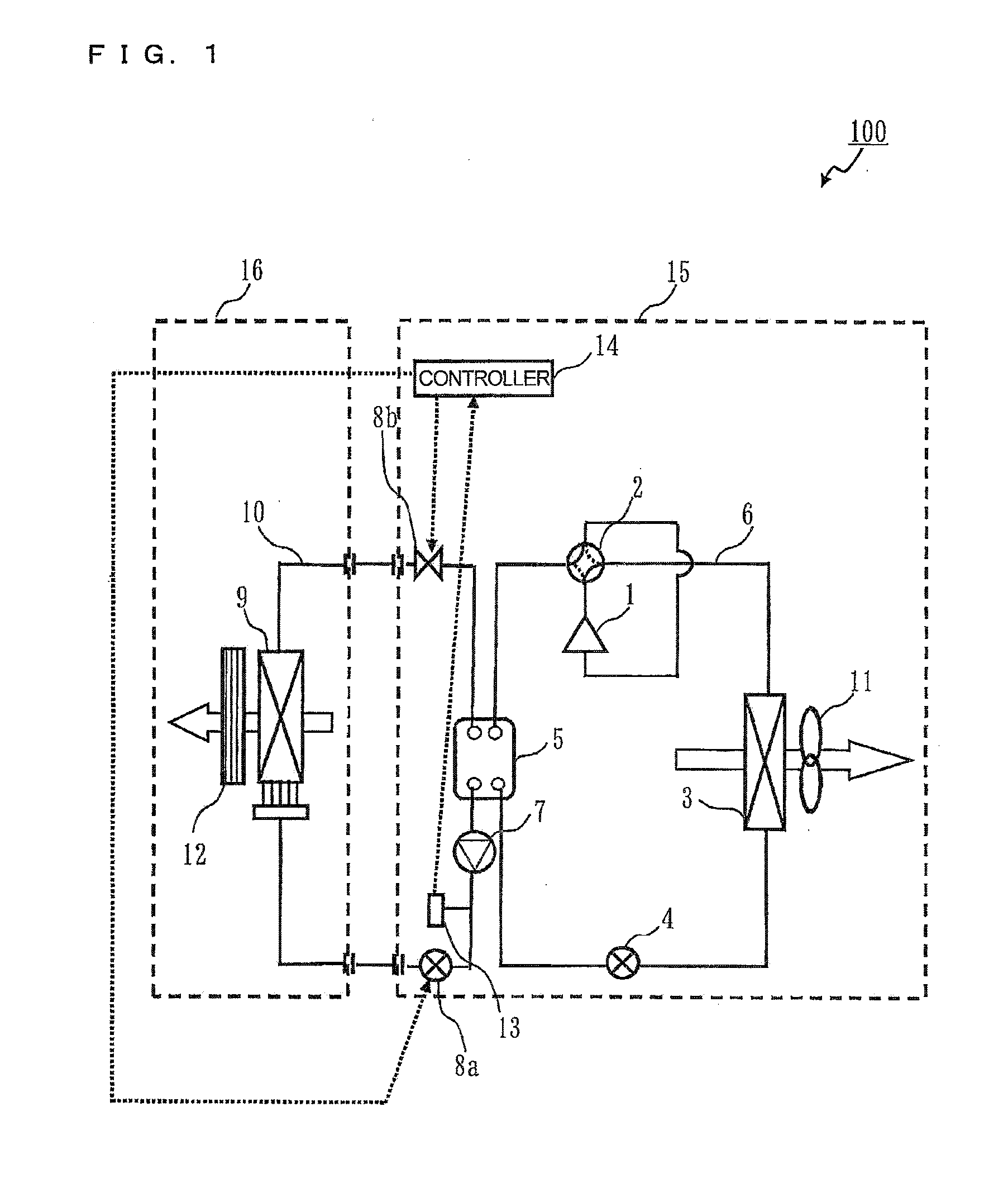

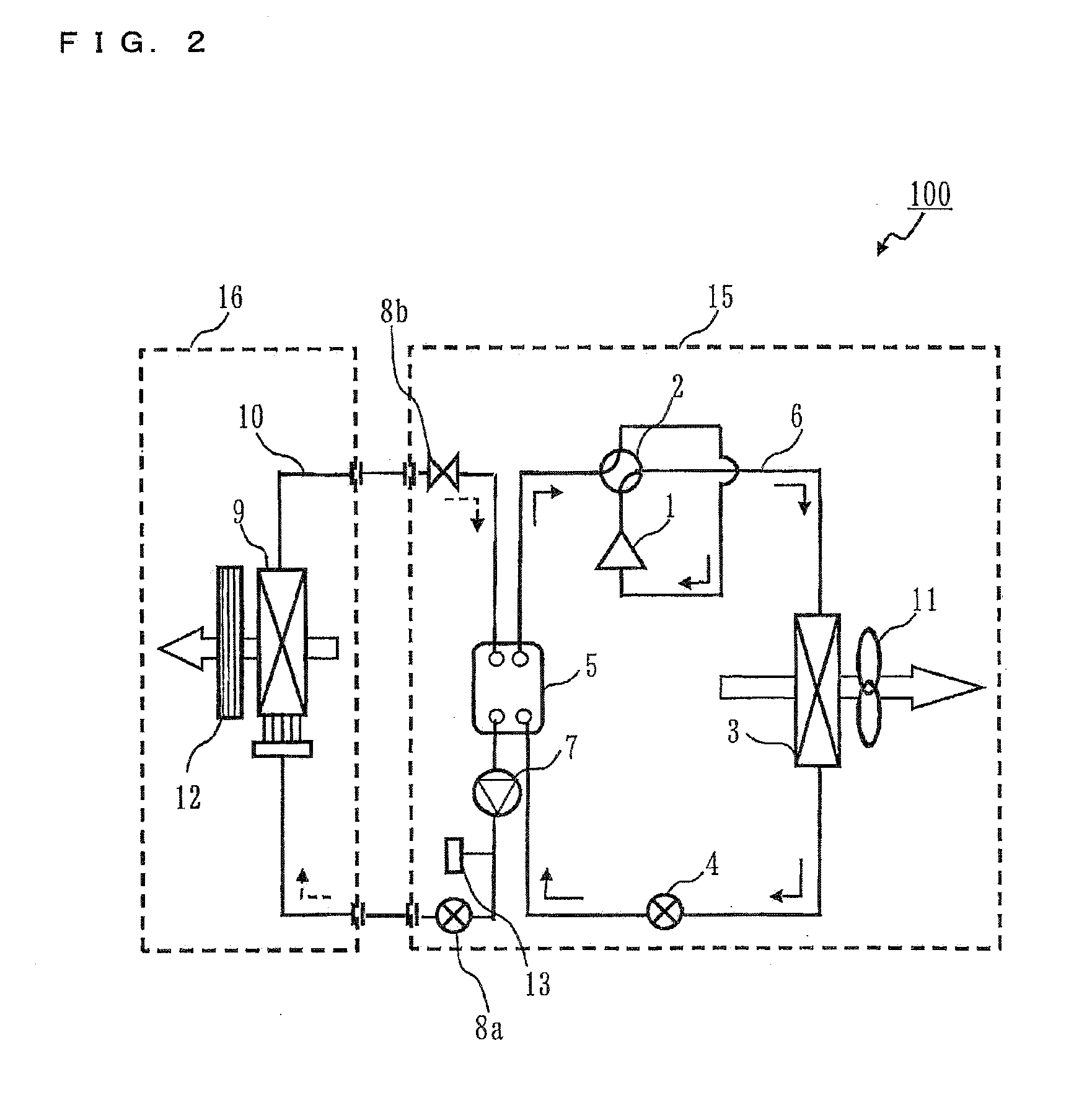

[0023]FIG. 1 is a diagram illustrating the configuration of an air-conditioning apparatus 100 according to Embodiment 1. In FIG. 1, each blanked arrow indicates the flow of air and each dotted arrow indicates the flow of a signal.

[0024]The air-conditioning apparatus 100 includes a refrigerant circuit 6 (first refrigerant circuit or primary circuit) that includes a compressor 1 (first compressor), a four-way valve 2, a heat exchanger 3 (first heat exchanger), an expansion valve 4 (first expansion mechanism), an intermediate heat exchanger 5 (first intermediate heat exchanger) sequentially connected in loop by pipes. The air-conditioning apparatus 100 further includes a water circuit 10 (fluid circuit or secondary circuit) that includes the intermediate heat exchanger 5, a pump 7, a valve 8a (first valve), a heat exchanger 9 (load heat exchanger), and a valve 8b (second valve) sequentially connected in loop by pipes. A flammable refrigerant, such as a propane or isobutane, having a lo...

embodiment 2

[0057]Embodiment 2 will be described with respect to an air-conditioning apparatus 100 including a plurality of primary circuits. Although the air-conditioning apparatus 100 including two primary circuits will be described below as an example, the air-conditioning apparatus 100 may include three or more primary circuits.

[0058]In the air-conditioning apparatus 100 according to Embodiment 2, the same components as those in the air-conditioning apparatus 100 according to Embodiment 1 are designated by the same reference numerals.

[0059]FIG. 5 is a diagram illustrating the configuration of the air-conditioning apparatus 100 according to Embodiment 2. In FIG. 1, each blanked arrow indicates the flow of air and each dotted arrow indicates the flow of a signal.

[0060]The air-conditioning apparatus 100 includes a refrigerant circuit 6a (first refrigerant circuit or primary circuit) including a compressor 1a (first compressor), a four-way valve 2a, a heat exchanger 3a (first heat exchanger), a...

embodiment 3

[0093]Embodiment 3 will be described with respect to placement of the intermediate heat exchanger 5 (5a, 5b) in Embodiments 1 and 2. The placement will be described with respect to the air-conditioning apparatus 100 according to Embodiment 2 as an example.

[0094]FIG. 8 is an exploded perspective view of a typical plate heat exchanger.

[0095]FIGS. 9 to 11 are diagrams illustrating arrangement of the intermediate heat exchangers 5a and 5b according to Embodiment 3. In FIGS. 9 to 11, solid line arrows indicate the flow of refrigerant during the cooling operation and broken line arrows indicate the flow of water. During the heating operation, the refrigerant flows in a direction opposite to that indicated by the solid line arrows. In FIGS. 9 to 11, an up-down direction corresponds to a vertical direction.

[0096]In FIGS. 9 to 11, it is assumed that each of the intermediate heat exchangers 5a and 5b is a plate heat exchanger. As illustrated in FIG. 8, the plate heat exchanger includes a plur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com