Method of preparation and composition of antimicrobial ice

a technology of antimicrobial ice and composition, which is applied in the field of preparation and composition of antimicrobial ice, can solve the problems that the method of producing non-equilibrium peracetic acid is not practical for smaller users, and achieves the effect of safer storage and handling for the end user and a much lower cost of feed chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

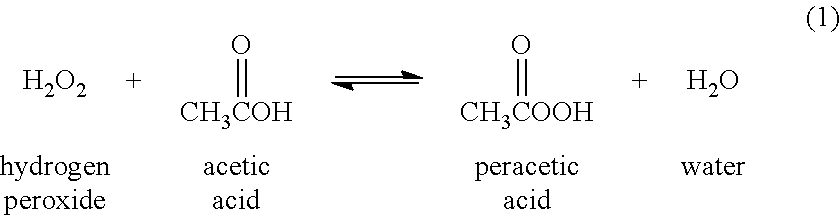

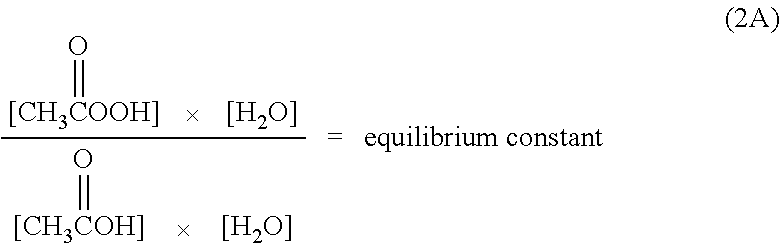

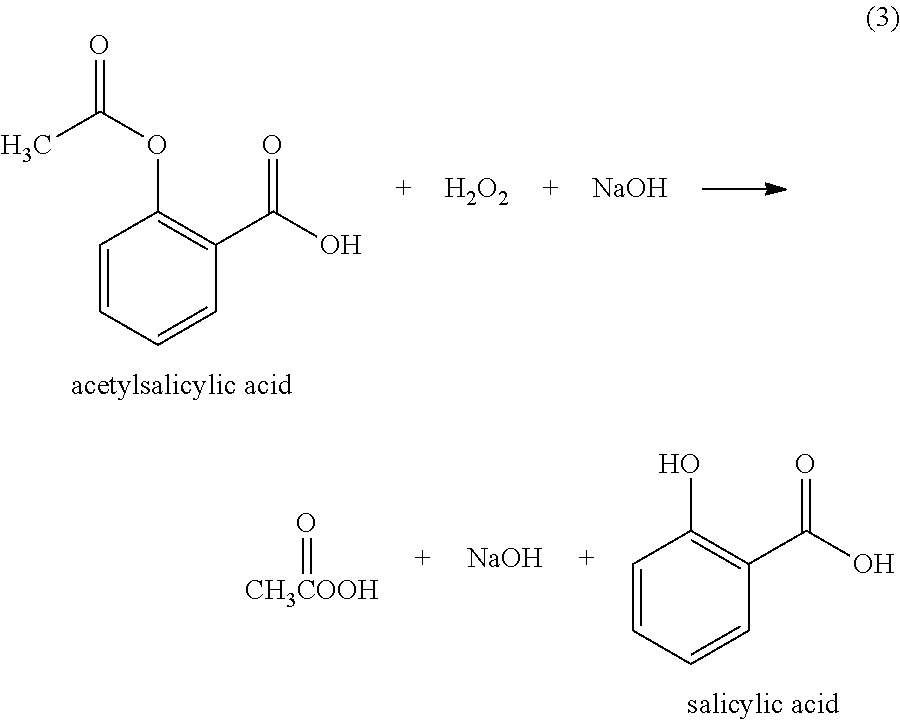

[0033]In the present invention non-equilibrium peroxycarboxylic acid solutions, particularly those of PAA, are chemically produced by an irreversible, non-equilibrium reaction of hydrogen peroxide with an acyl donor, particularly an acetyl donor, in a solvent such as, but not limited to, water. One typical example of this reaction using acetylsalicylic acid as the acetyl donor is given in the equation below. Caustic pH (pH>10) is used to accelerate the reaction since the hydrogen peroxide anion is a much better nucleophile than hydrogen peroxide. The reaction pH can be adjusted with an appropriate base (proton acceptors such as hydroxide or amines for example).

[0034]Both the hydrogen peroxide anion and hydroxide anion compete in the reaction with the acyl donor, the former producing a peroxycarboxylic acid and the latter producing carboxylic acid. When an acetyl donor is employed the hydrogen peroxide anion and hydroxide anion compete in the reaction with the acetyl donor, the forme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pH | aaaaa | aaaaa |

| concentrations | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com