Multiple compartment container

a multi-compartment, container technology, applied in the field of containers, can solve the problems of inconvenient consumption of convenience foods in containers, inability to maintain the desired organoleptic and texture properties of these foods, and unpleasant taste, so as to prevent leakage and minimize risk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

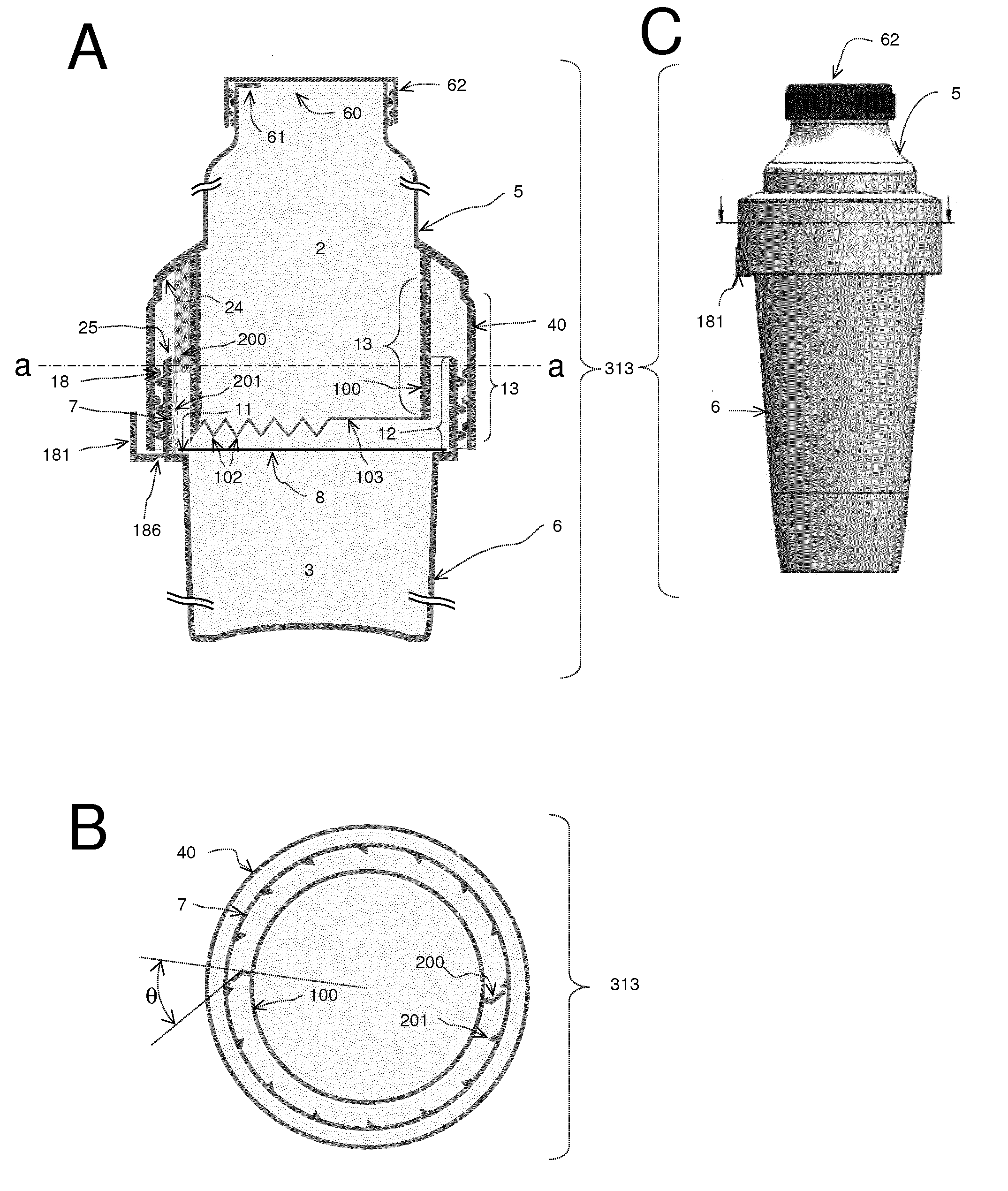

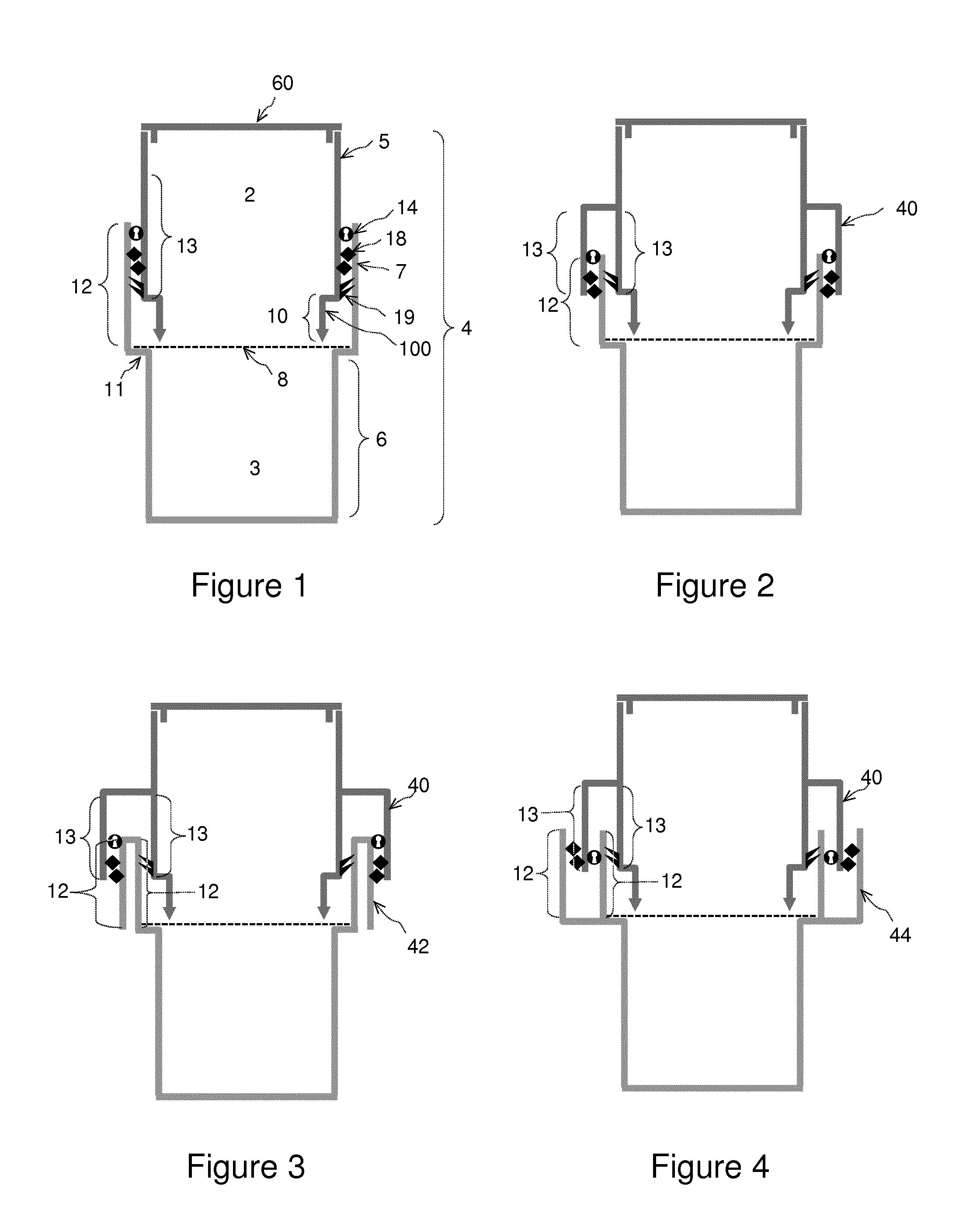

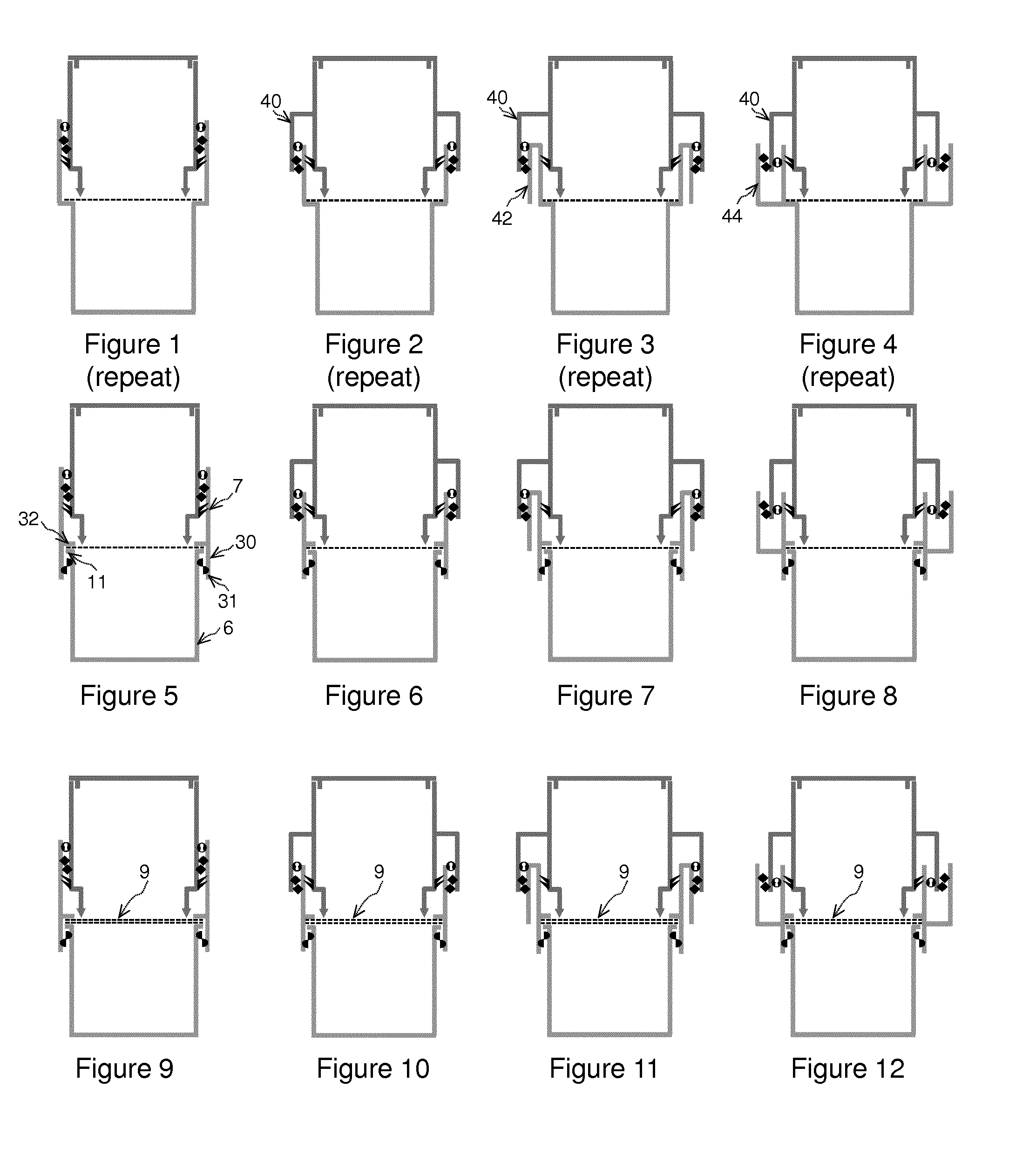

[0155]A particular embodiment of the container according to the present invention is presented in FIGS. 49 and 50. The container of this embodiment is an elaboration of the embodiment schematically represented in FIG. 2. The container (313) according to this illustrative embodiment comprises an upper (2) and lower compartment (3) separated by an intercompartment membrane (8) and is obtained by assembling two individual members, referred to as the upper (311) and lower member (312). Preferably, the upper (311) and lower member (312) are made in a plastic material using injection moulding.

[0156]The lower member (312) has a cup shape and comprises a circumferential rim (11) from which extends upwards a circumferential collar (7). At its inner side said circumferential collar (7) comprises a plurality of longitudinal ridges (201). At its outer side the circumferential collar (7) comprises part of a guidance means (18) in the form of external helical threads (170). The lower member (312)...

example 2

[0161]A particular embodiment of the container according to the present invention is presented in FIG. 51. The container of this example is an elaboration of the embodiment schematically represented in FIG. 3. The container (323) according to this illustrative embodiment comprises an upper (2) and lower compartment (3) separated by an intercompartment membrane (8) and is obtained by assembling two individual members, referred to as the upper member (321) and lower member (322). Preferably, the upper member (321) and lower member (322) are made in a plastic material using injection moulding.

[0162]The lower member (322) has a cup shape and comprises a circumferential rim (11) from which extends upwards a circumferential collar (7), which at its top is connected via a top rim (46) to an external circumferential wall (42) depending downwards from said top rim (46). The external circumferential wall (42) of the lower member (322) has an internally recessed zone (204), from which extends ...

example 3

[0166]A particular embodiment of the container according to the present invention is presented in FIG. 52. The container of this example is an elaboration of the embodiment schematically represented in FIG. 4. The container (333) according to this illustrative embodiment comprises an upper (2) and lower compartment (3) separated by an intercompartment membrane (8) and is obtained by assembling two individual members, referred to as the upper (331) and lower member (332). Preferably, the upper (331) and lower member (332) are made in a plastic material using injection moulding.

[0167]The lower member (332) has a cup shape and comprises a circumferential rim (11) from which extends upwards an internal (7) and external (44) circumferential collar. A rim section (47) connects at least part of the bottom end of the external circumferential collar (44) with bottom end of the internal circumferential collar (7). The internal circumferential collar (7) comprises at its outer side a circumfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com