Electrostatic induction generation device and electrostatic induction generation apparatus having a movable electrode formed between a first fixed electrode substrate and a second fixed electrode substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

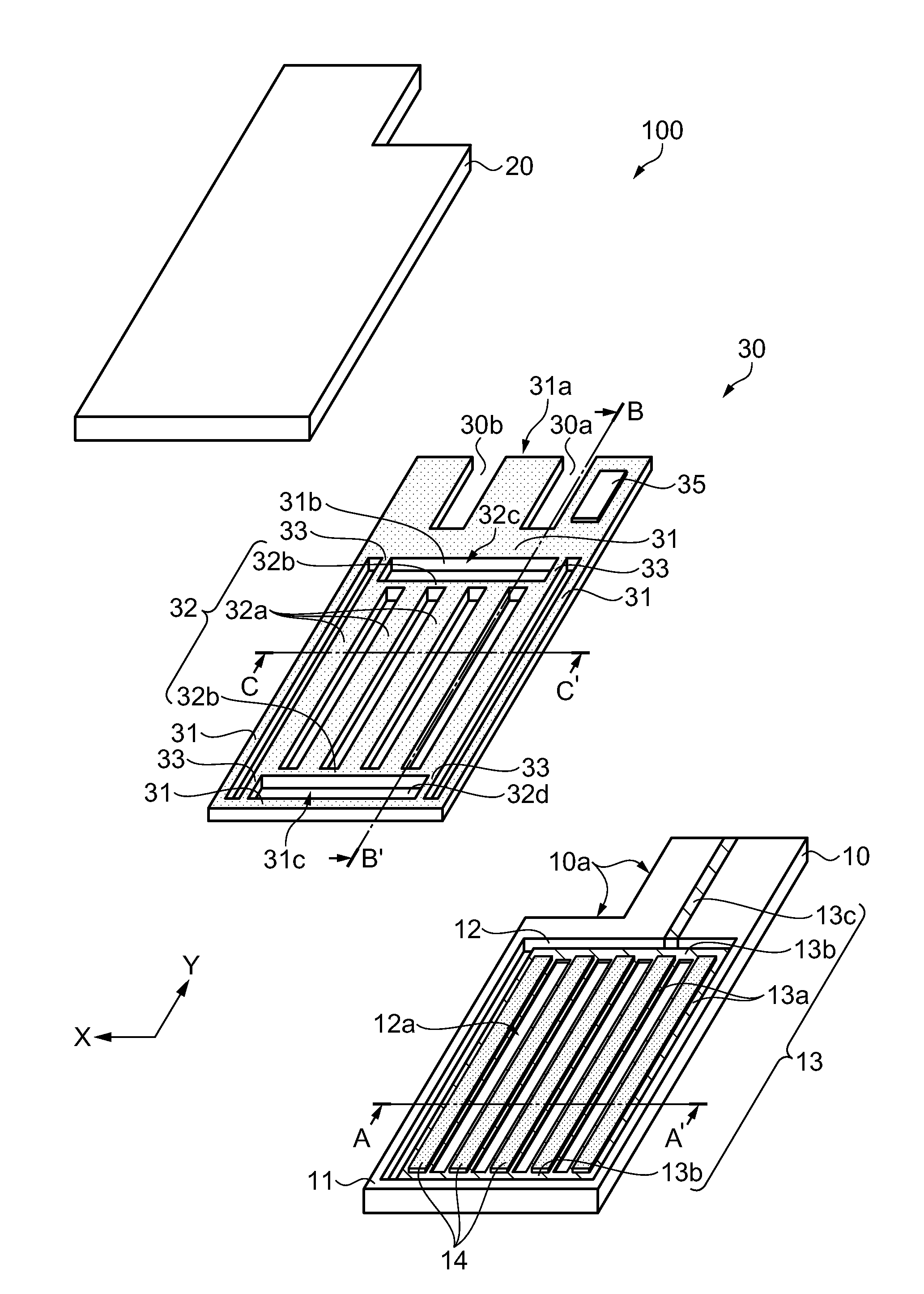

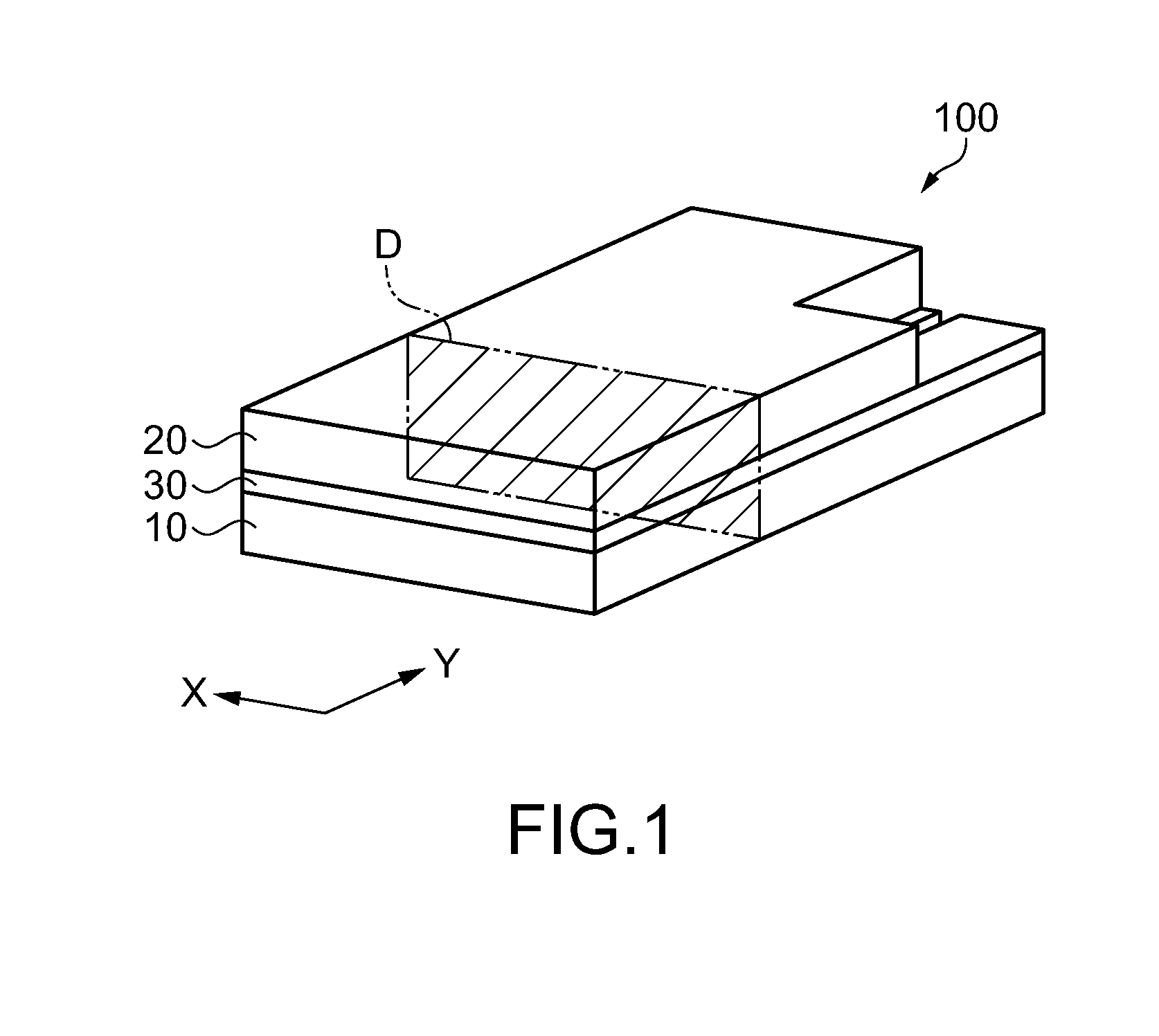

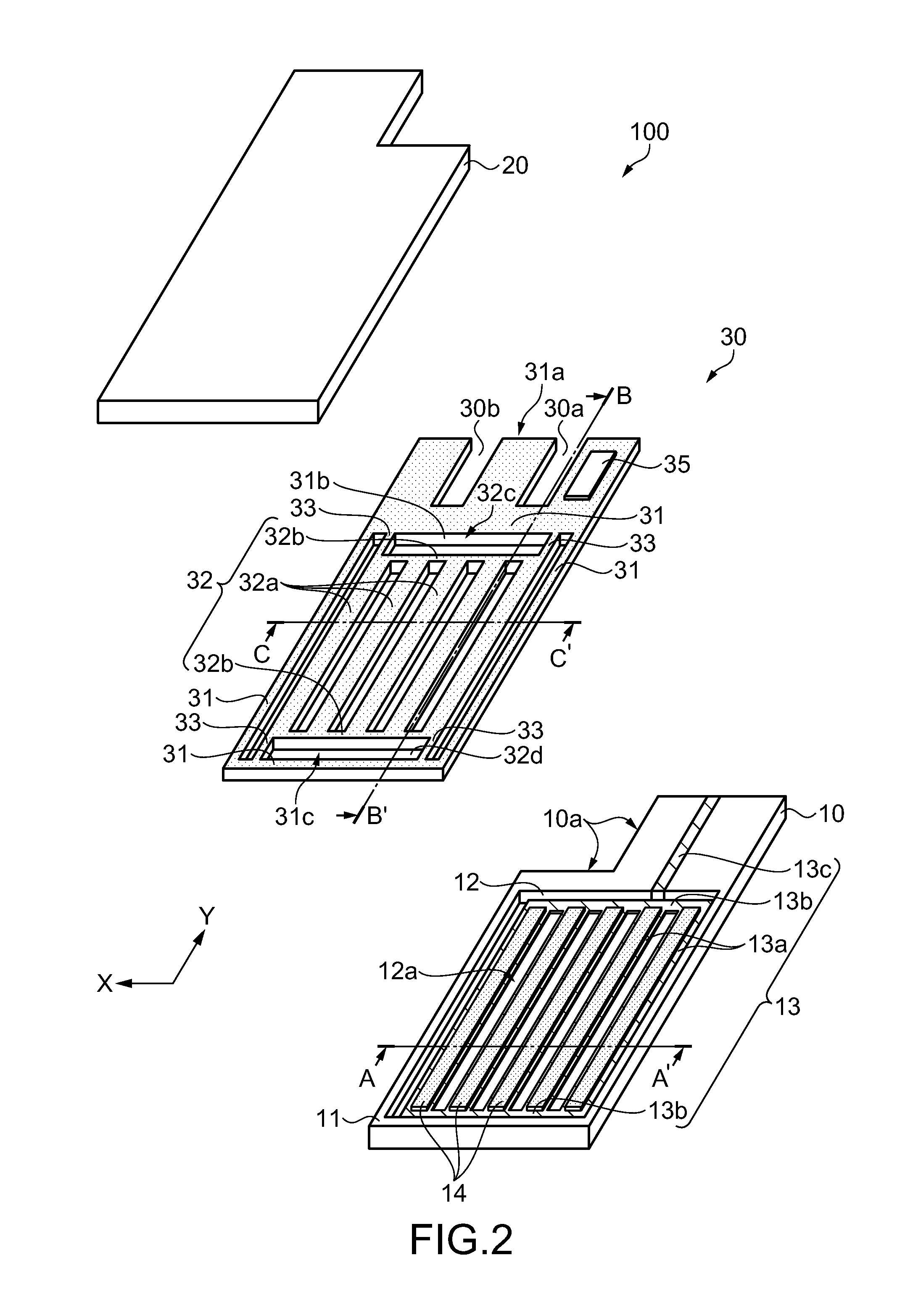

[0031]FIG. 1 is an external perspective view showing the electrostatic induction generation device according to the present embodiment. The electrostatic induction generation device 100 shown in FIG. 1 is composed of a first substrate 10 as a first fixed electrode substrate provided with an electret on the fixed electrode described later, a movable substrate 30 provided with a movable section, and a second substrate 20 as a second fixed electrode substrate provided with the electret on the fixed electrode, stacked so that the first substrate 10 and the second substrate 20 sandwich the movable substrate 30.

[0032]FIG. 2 is an external perspective view of the electrostatic induction generation device 100 shown in FIG. 1 in an exploded state. The first substrate 10 is a glass substrate, and borosilicate glass, for example, is preferably used therefor. One surface 11 (hereinafter referred to as an electrode forming surface 11) of the first substrate 10 is provided with a recess 12, and a...

second embodiment

[0052]A second embodiment of the invention is shown in FIG. 8. Similarly to the first embodiment, the electrostatic induction generation device 200 shown in FIG. 8 is provided with a movable substrate 230, and a first substrate 210 and a second substrate 220 disposed so as to sandwich the movable substrate 230. The movable substrate 230 has a movable electrode holding frame 231 formed along the outer shape thereof to have a frame shape. A movable electrode 232A and a movable electrode 232B are coupled to the movable electrode holding frame 231 via electrode support beams 233a, 233b. The extending directions of the movable electrode fingers 232a, 232b provided to the respective movable electrodes 232A, 232B are perpendicular to each other. Specifically, in the drawing, the movable electrode fingers 232a are formed so as to extend in the Y direction, and the movable electrode fingers 232b are formed so as to extend in the X direction.

[0053]The first substrate 210 used for sandwiching ...

third embodiment

[0057]As a third embodiment of the invention, an electrostatic induction generation apparatus using the electrostatic induction generation device according to the first embodiment will be explained. FIG. 9 is a block diagram showing the electrostatic induction generation apparatus 1000 according to the third embodiment of the invention. The electrostatic induction generation apparatus 1000 is provided with the electrostatic induction generation device 100, a power control section 300, and a charging section 400, and supplies the drive device 500 to be a drive object with the electricity thus generated.

[0058]The electricity generated by the electrostatic induction generation device 100 is taken out as an irregular current. The power control section 300 converts the irregular current into stable electricity, and then supplies the drive device 500 with the electricity. Further, if the supply of the electricity to the drive device 500 is not required, the power control section 300 suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com