Composite airfoil assembly

a technology of airfoil and composite blades, which is applied in the direction of waterborne vessels, climate sustainability, machines/engines, etc., can solve the problems of labor-intensive and costly manufacturing arrangements, adds cost to the component, and is not suitable for use in the field of composite blade assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

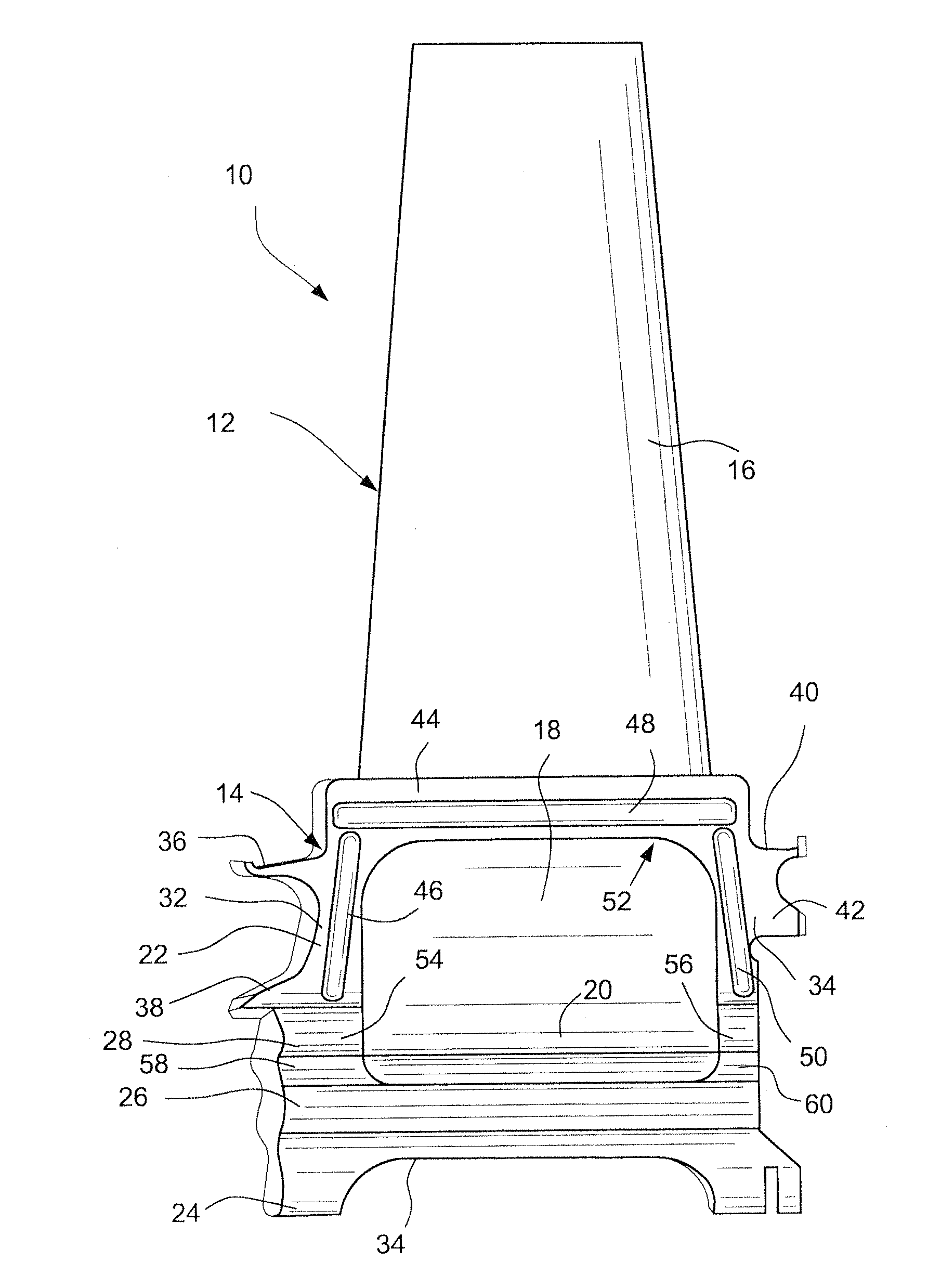

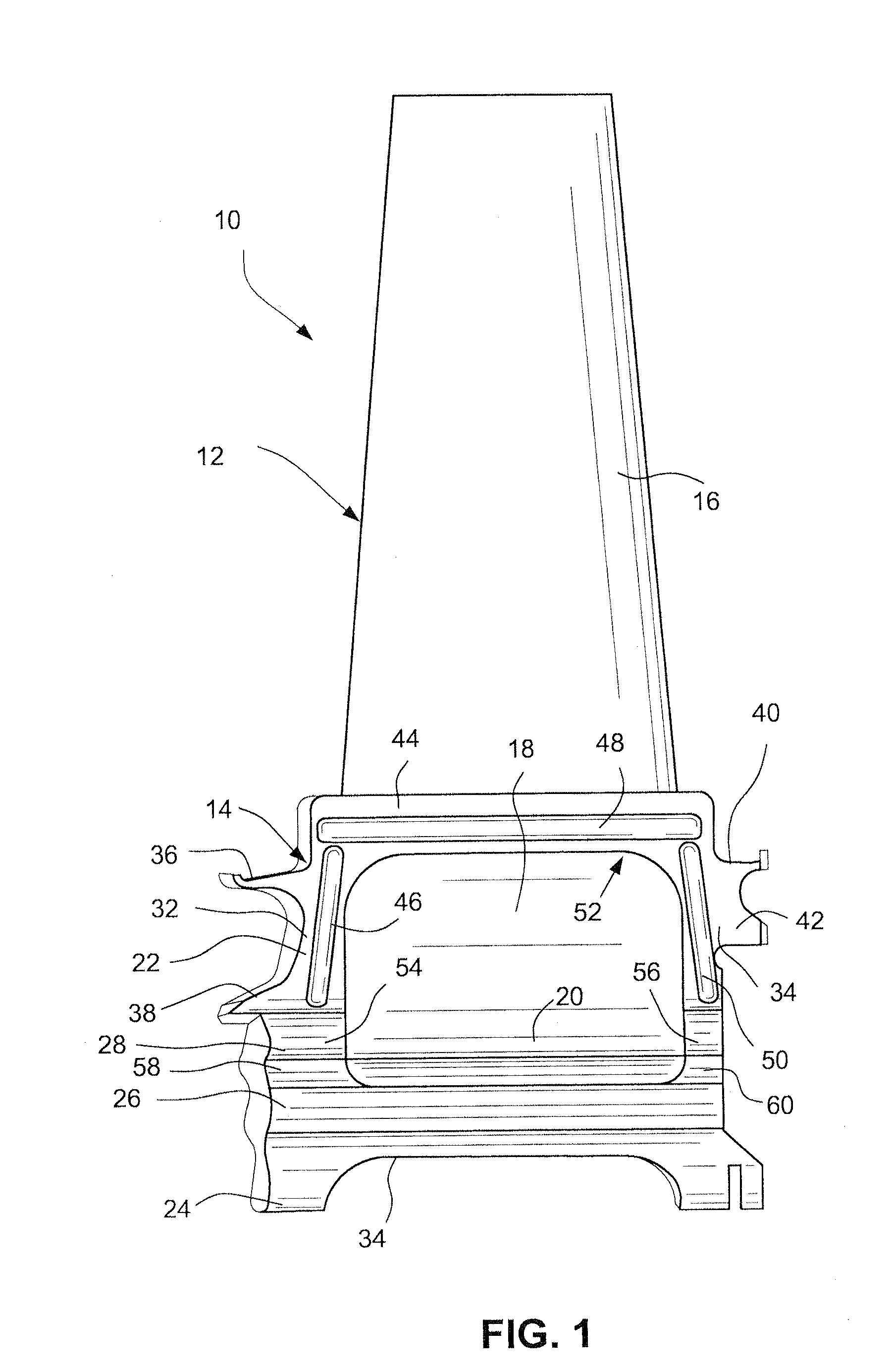

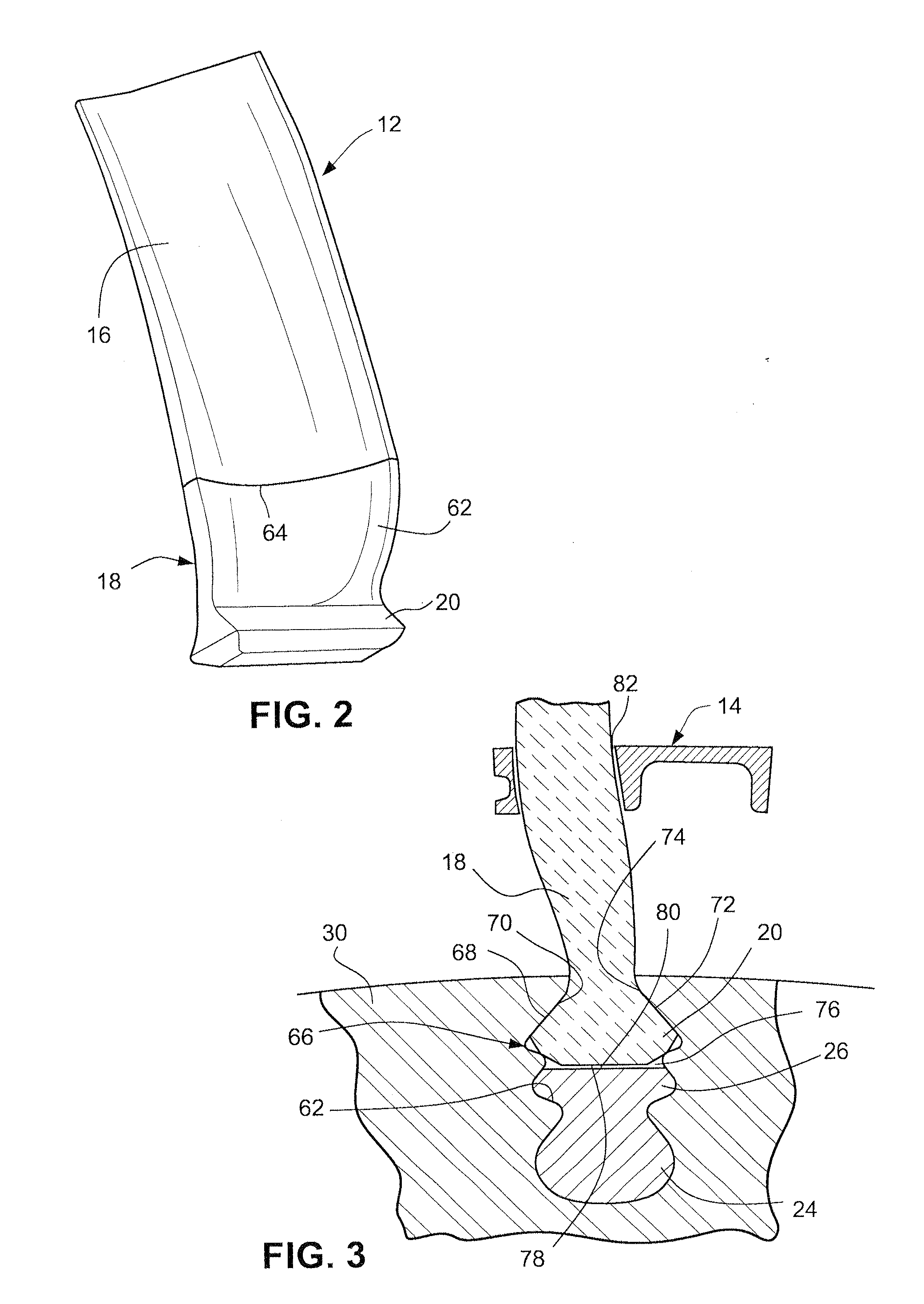

[0015]With reference initially to FIGS. 1-3, a composite blade assembly 10 in accordance with an exemplary but nonlimiting embodiment of the invention includes a ceramic airfoil 12 and a metal platform 14. As best seen in FIG. 2, the ceramic airfoil 12 includes an airfoil portion 16 a shank portion 18 and a dovetail tang 20 at its radially innermost end.

[0016]The metal platform 14 (FIG. 1) includes a platform shank 22 and oppositely-extending and otherwise conventional platform dovetail tangs 24, 26 and 28 that are adapted to be received in a mating slot formed in a rotor wheel 30 (see FIG. 3) as described further herein. The platform shank 22 includes opposite shank ends 32, 34 provided with angel wing seals 36, 38 on one end, and seals 40, 42 on the opposite end. One or both of the so-called “slash faces” (one shown at 44) may be formed with elongated grooves 46, 48, 50 to allow placement of axial and / or radial pin seals (not shown), if required. The metal platform 14 is thus seen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com