Piston engine drivable using a steam power process

a steam power process and piston engine technology, applied in the field of piston engines, can solve the problem of inflexible structure form, and achieve the effect of sufficient working volume and good degree of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

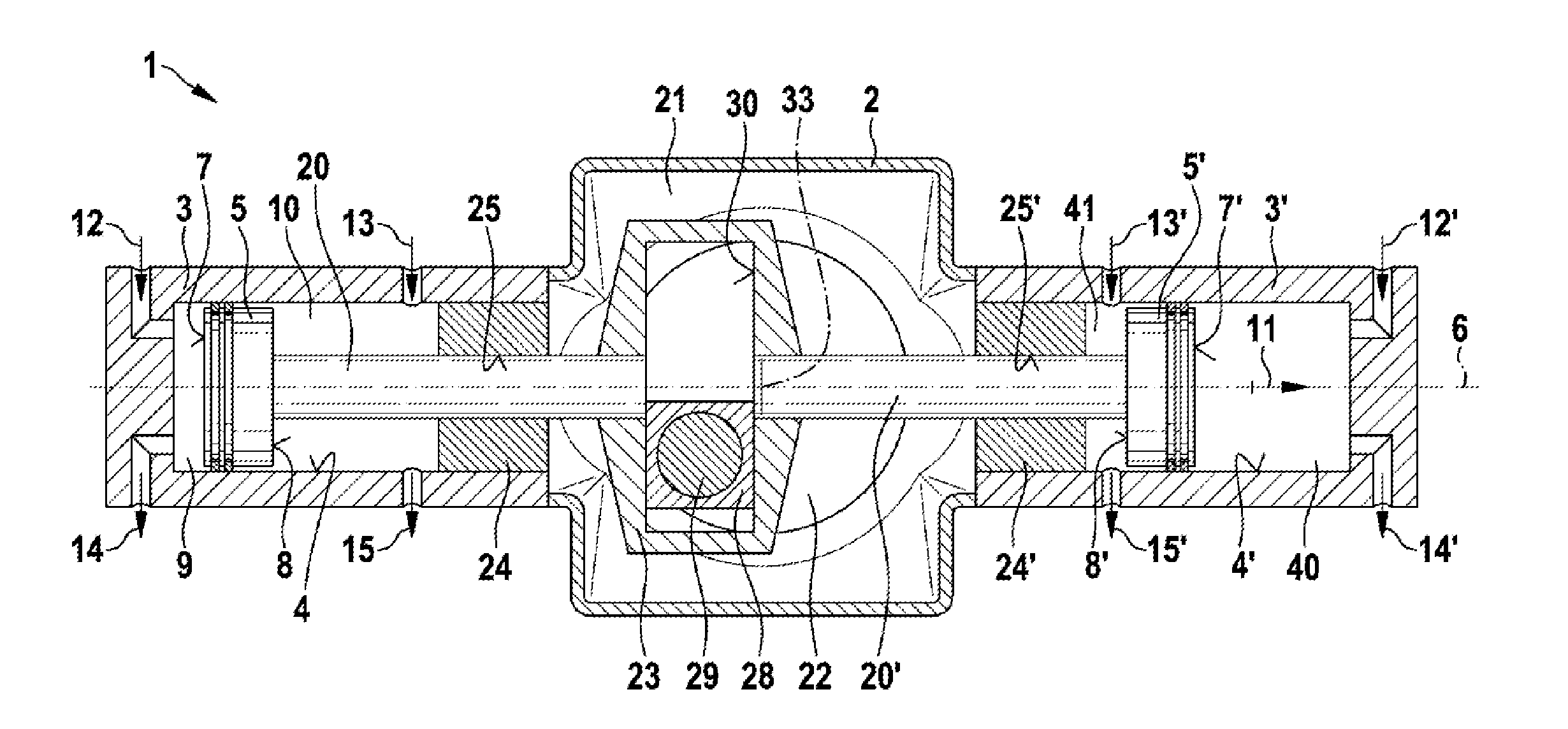

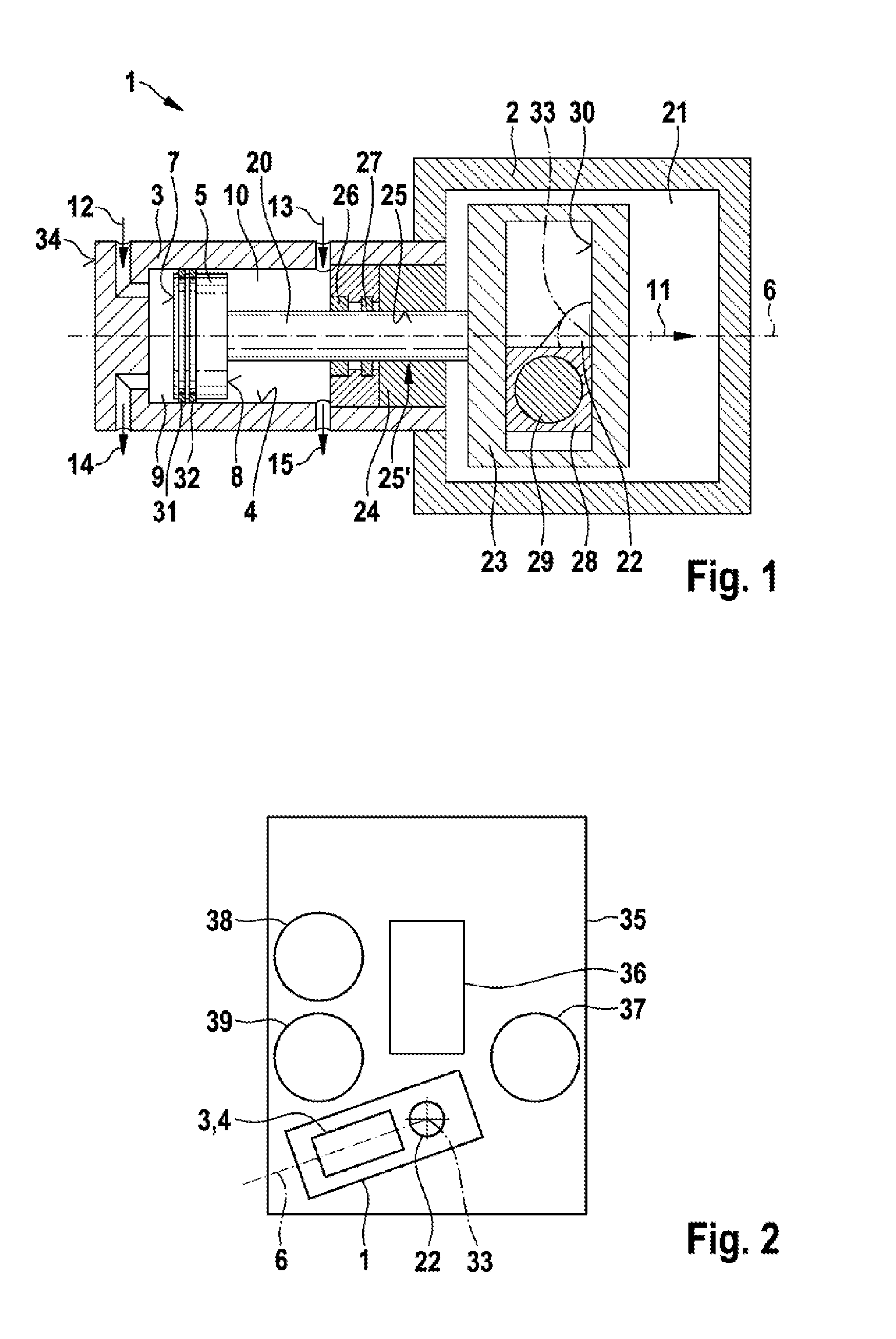

[0031]FIG. 1 is a schematic illustration of a piston engine 1 in accordance with the invention. The piston engine 1 is driven via a steam power process. In this instance, the piston engine 1 can be used particularly in an internal-combustion engine of a motor vehicle in order to use the waste heat of the internal-combustion engine. The piston engine 1 then converts the waste heat into mechanical energy which can be used, for example, as additional drive energy or to drive an auxiliary unit, in particular an electrical generator. However, the piston engine 1 according to the invention is also suitable for other applications.

[0032]The piston engine 1 has a housing portion 2 and a cylinder 3 which is connected to the housing portion 2. In this embodiment, the piston engine 1 has precisely one cylinder 3.

[0033]The cylinder 3 of the piston engine 1 has a cylinder bore 4, in which a cylinder piston 5 is arranged. The cylinder piston 5 is arranged in this instance in the cylinder bore 4 in...

second embodiment

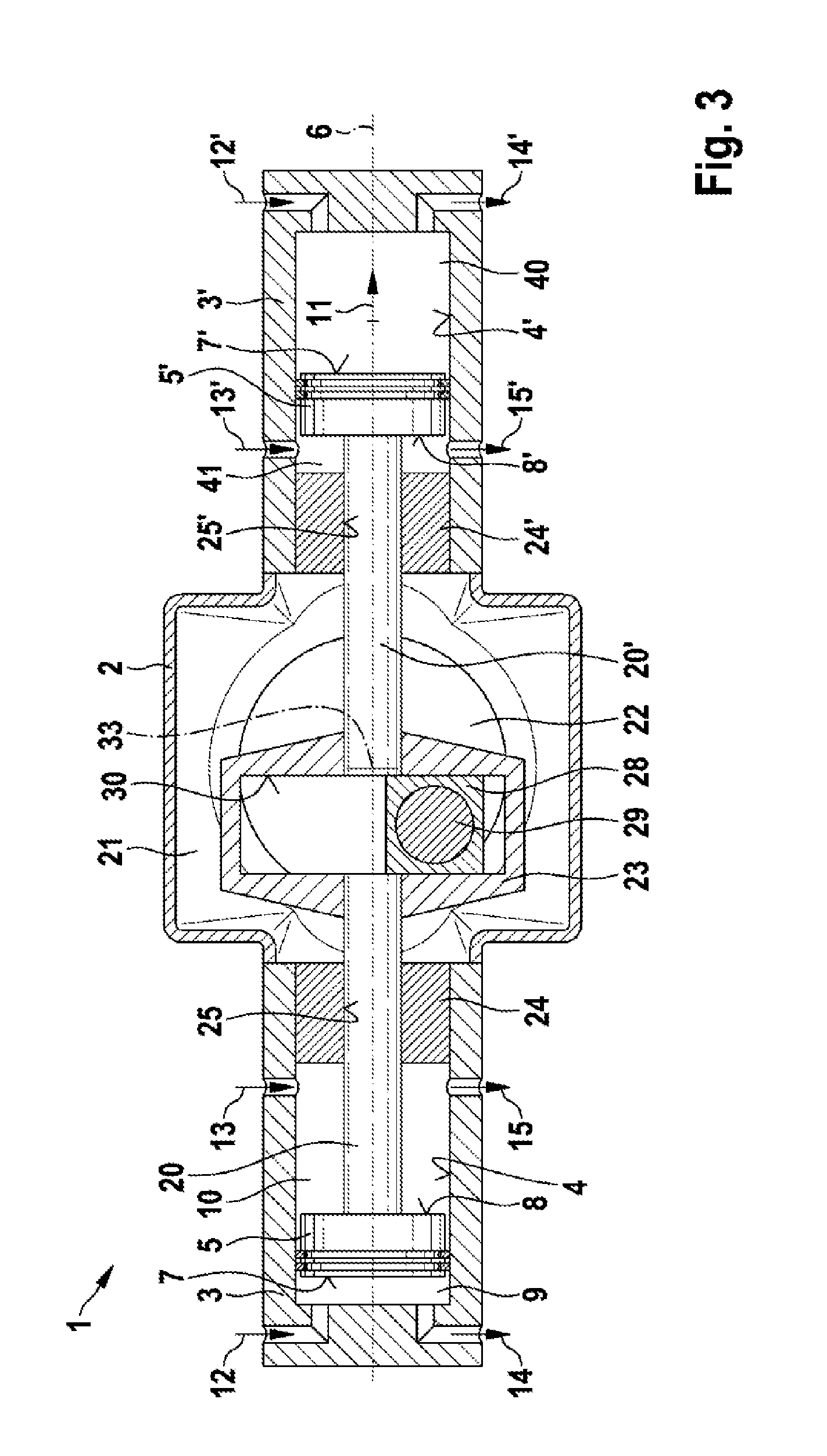

[0045]FIG. 3 is a schematic cross section of the piston engine 1 illustrated in FIG. 1 in accordance with a In this embodiment, the piston engine 1 has an additional cylinder 3′. An additional cylinder bore 4′, in which an additional cylinder piston 5′ is arranged, is constructed in the additional cylinder 3′. The additional cylinder piston 5′ can also be actuated along the axis 6 in this instance. The cylinder piston 5′ has a first lateral face 7′ and a second lateral face 8′. At the first lateral face 7′, the cylinder piston 5′ delimits a third operating space 40. At the second lateral face 8′, the cylinder piston 5′ delimits a fourth operating space 41. The cylinder piston 5′ can be actuated together with the cylinder piston 5 so that both cylinder pistons 5 are displaced either in the direction 11 or counter to the direction 11.

[0046]Inlets 12′, 13′ are provided in the additional cylinder 3′. Furthermore, outlets 14′, 15′ are provided in the additional cylinder 3′. The inlet 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com