Urinal drain trap

a technology for drain traps and urinals, applied in urinals, water installations, construction, etc., can solve the problems of reducing the amount of sealing liquid and thinning the sealing layer, clogging the ascending flow path, and foul odor of collected urine, so as to prevent the occurrence of siphon action, prevent the flow path area of the outflow conduit, and prevent the effect of siphon action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

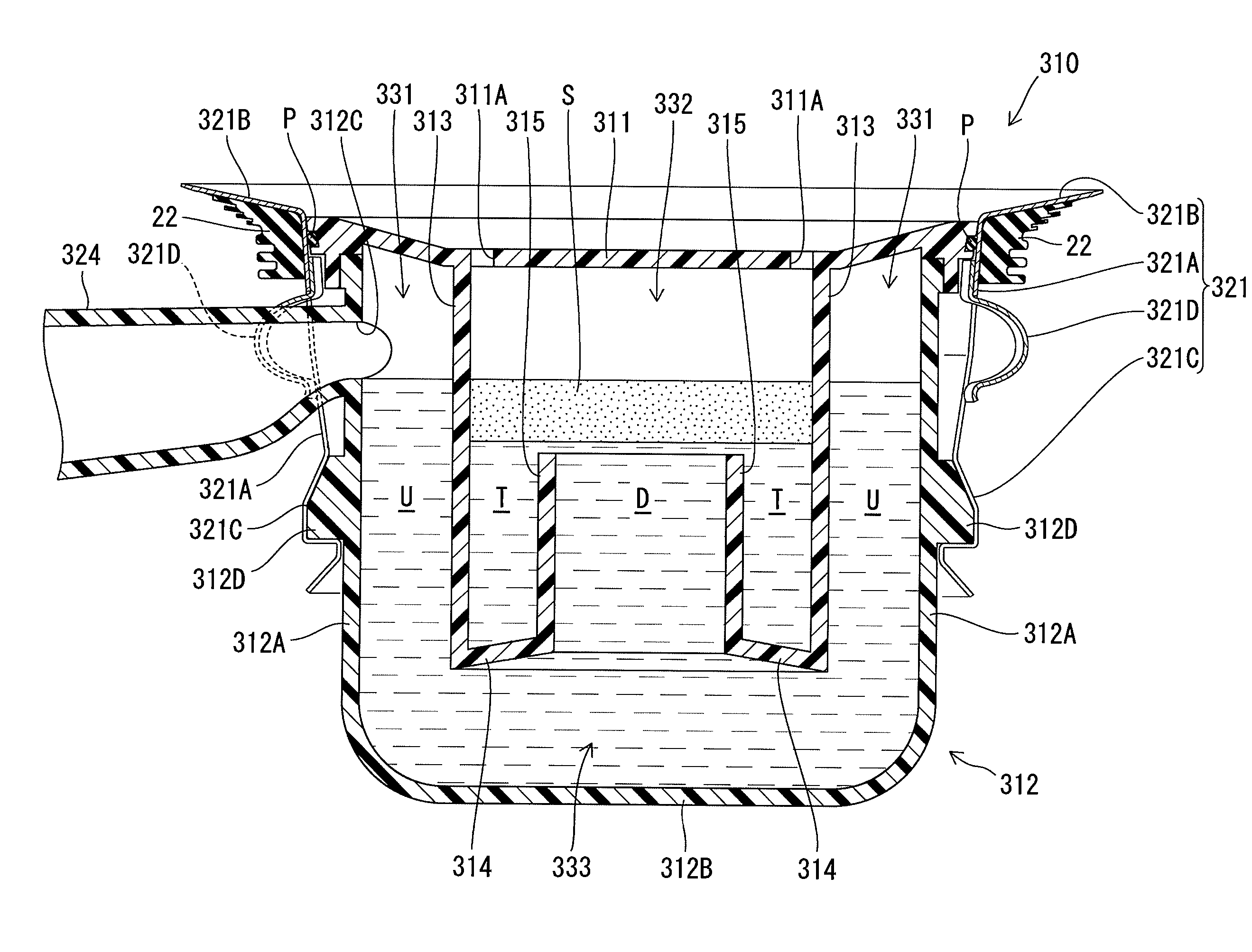

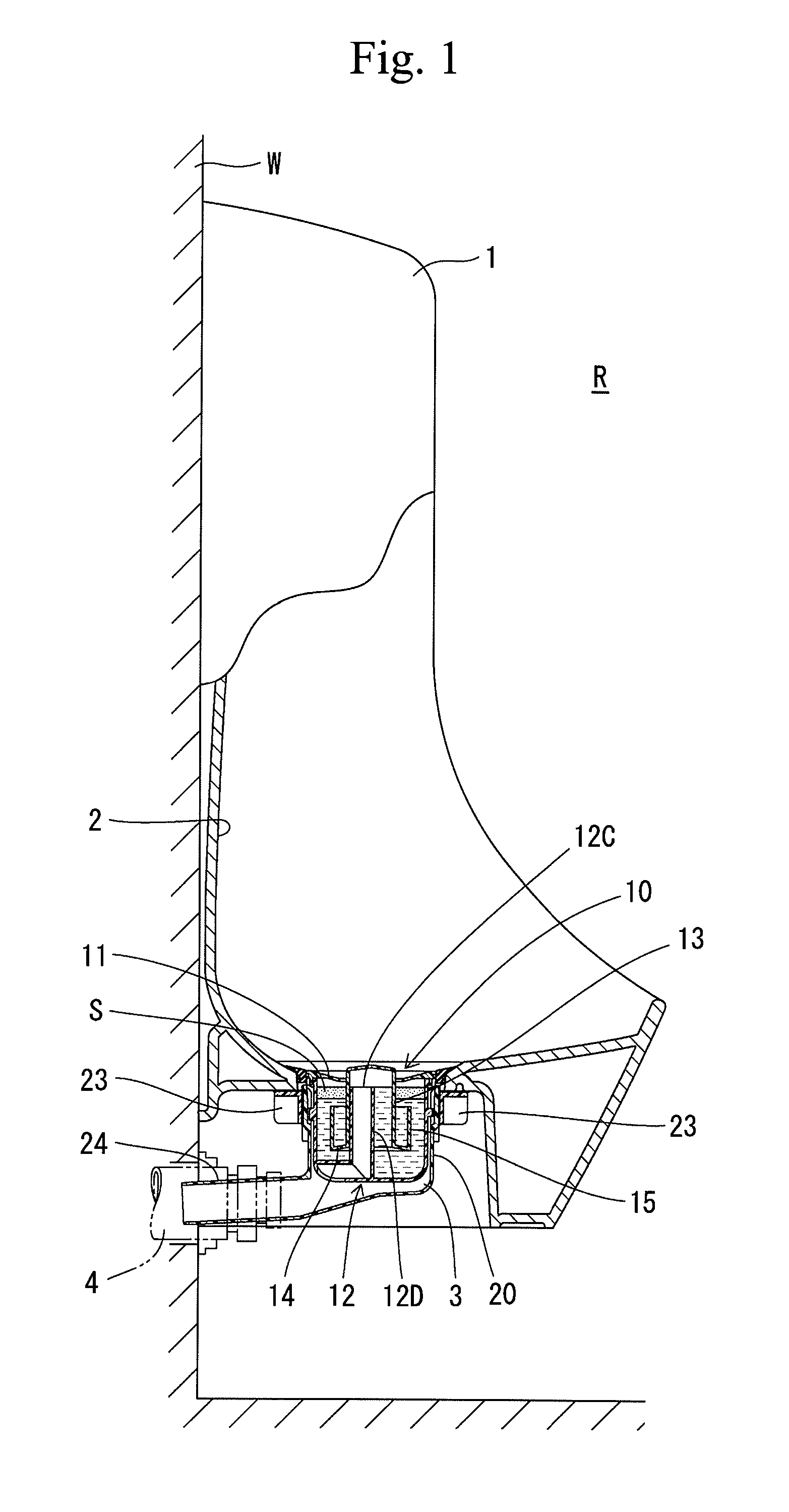

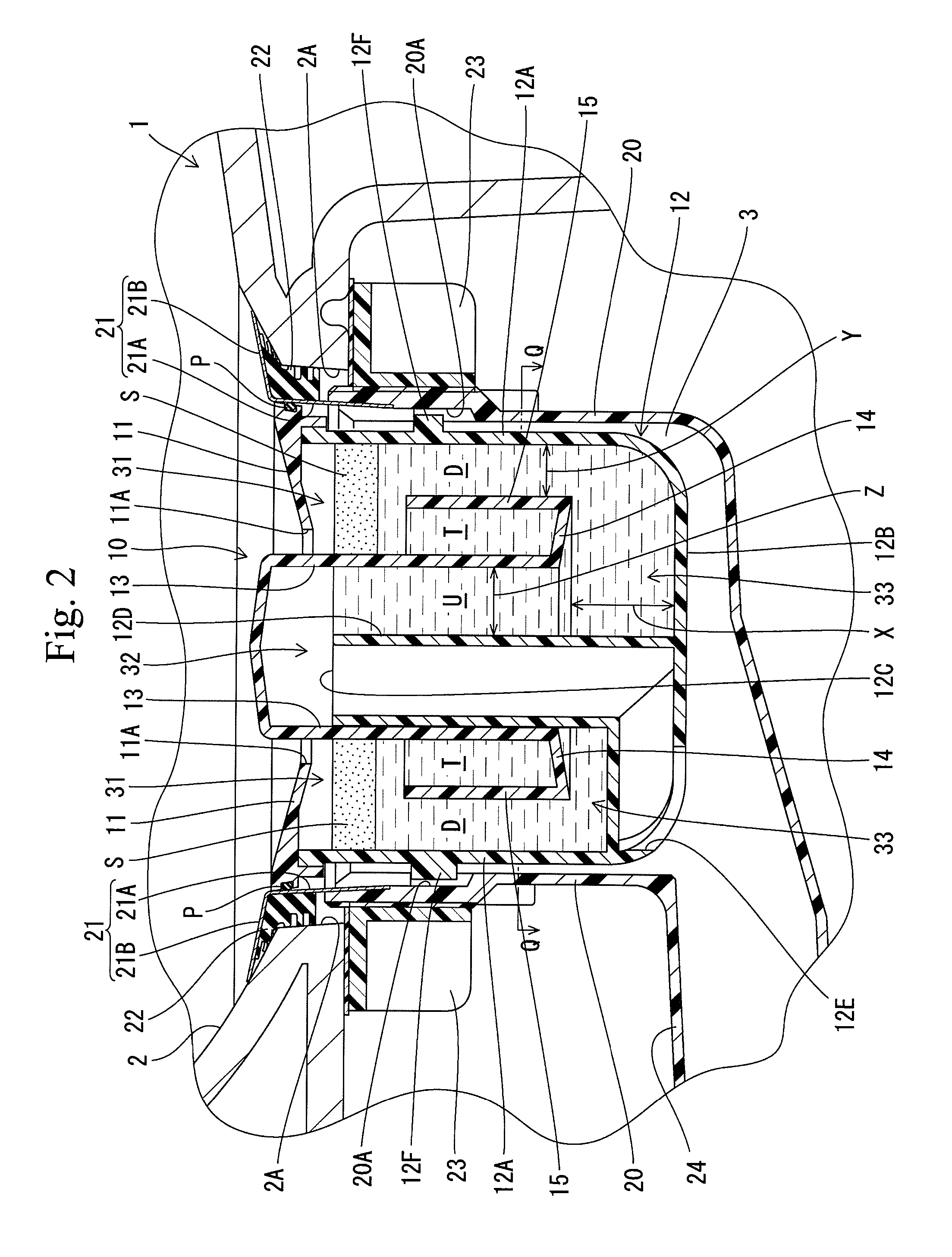

[0043]The urinal drain trap 10 according to embodiment 1 is formed into a cartridge type and detachably mounted in a recess 3 which is upwardly open at a lower end of a bowl surface 2 of a urinal 1 as shown in FIGS. 1 to 3 and 4A. The urinal 1 is of a wall-mounted type and is fixed to a wall surface W of a toilet room R. The recess 3 is formed into a cylindrical storage container 20 which is mounted on a lower end of the bowl surface 2 of the urinal 1 and has an open upper end and a bottom.

[0044]The storage container 20 has an upper end to which a locking member 21 is connected. The locking member 21 is connected to an upper part of an inner surface of the storage container 20 and includes an upwardly extending cylindrical portion 21A and a ring-shaped flange 21B spreading outward from an upper end of the cylindrical portion 21A. A locking recess 20A is formed in a middle part of the inner surface of the storage container 20. A locking convexity 12F provided on a sidewall 12A of a b...

embodiment 2

[0068]The urinal drain trap 110 according to embodiment 2 includes a body 112 directly mounted on a lower end of the bowl surface 2 of the urinal 1 as shown in FIG. 5. The locking member 21 is connected to the upper end of the body 112. The body 112 is inserted from above into the opening 2A formed in the lower end the bowl surface 2, so that the flange 21B of the locking member 21 is locked by an upper surface of the peripheral portion of the opening 2A. A threaded portion is formed in an upper part of the outer surface of the body 112. The ring-shaped fastening member 23 is fitted with the body 112 from below and has an upper surface which is locked to the underside of the peripheral edge of the opening 2A. The fastening member 23 is screwed into the threaded portion formed in the outer surface of the body 112. The peripheral edge of the opening 2A is thus held between the flange 21B of the locking member 21 and the fastening member 23, whereby the body 112 is mounted in the openi...

embodiment 3

[0075]In the urinal drain trap 210 according to embodiment 3, the outflow conduit 212D is formed into a cylindrical shape and is coaxial with the sidewall 212A of the body 212 as shown in FIG. 6. The outflow conduit 212D is also coaxial with the partition wall 13. As a result, the urine ascending flow path U is defined between the periphery of the outflow conduit 212D and the partition wall 13. The drain hole 212E facing the upstream portion of the connecting conduit 24 of the storage container 20 is formed in a central part of the bottom 212B of the body 212. The other construction of the urinal drain trap 210 according to the embodiment 3 is the same as that according to the embodiment 1. Identical parts in the embodiment 3 are labeled by the same reference symbols as those in the embodiment 1 and detailed description of these parts will be eliminated.

[0076]In the urinal drain trap 210 having the above-described construction, too, much of the sealing liquid drawn below the sealing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com