Press system

a technology of press system and press plate, which is applied in the direction of forging/pressing/hammering apparatus, forging/hammering/pressing machines, and shaping tools, etc., can solve the problems of product panel bursting or being torn at a portion, reducing the marketability of molded product panels, and increasing the cost. achieve the effect of preventing a product panel from bursting or being torn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

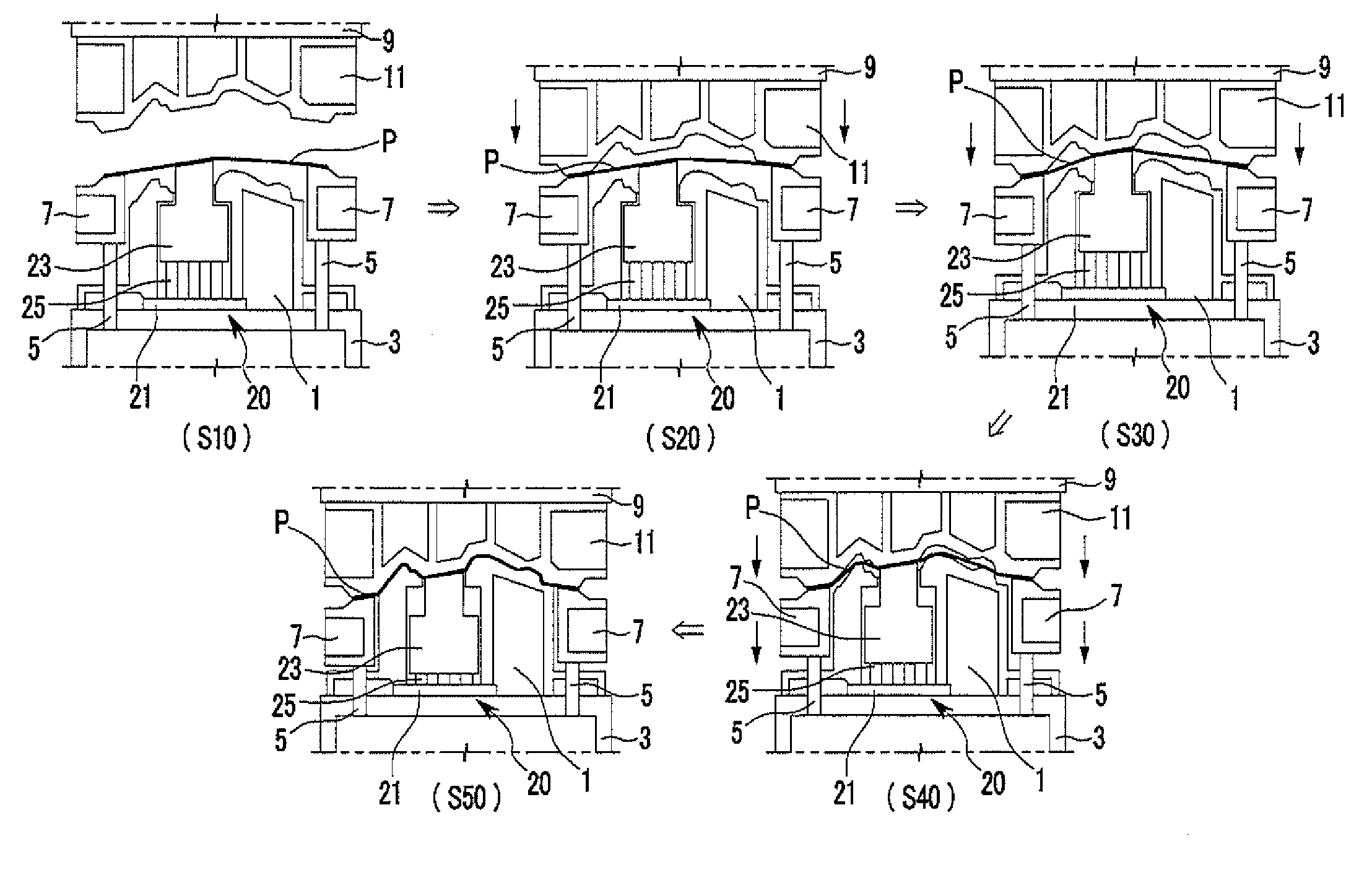

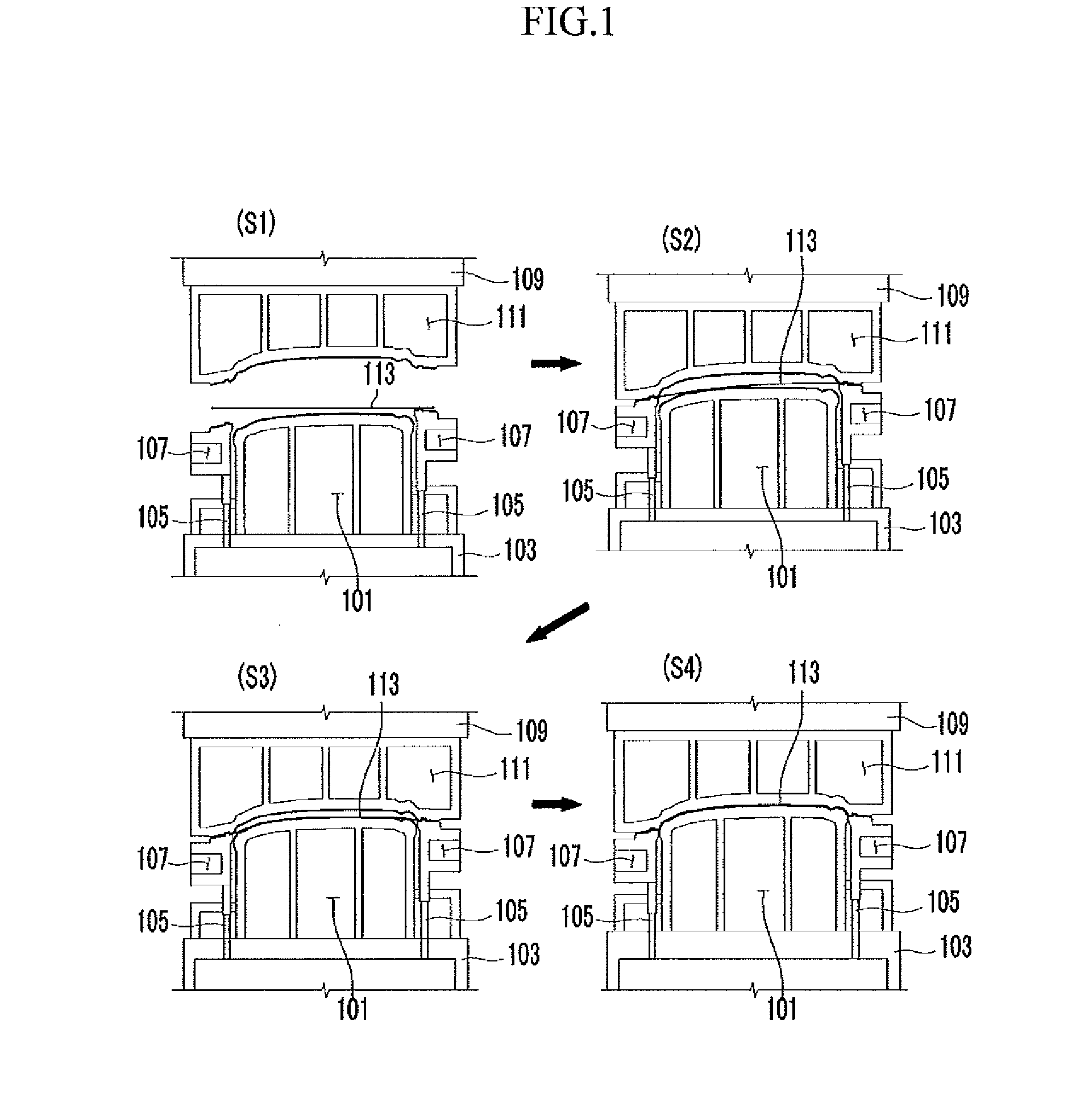

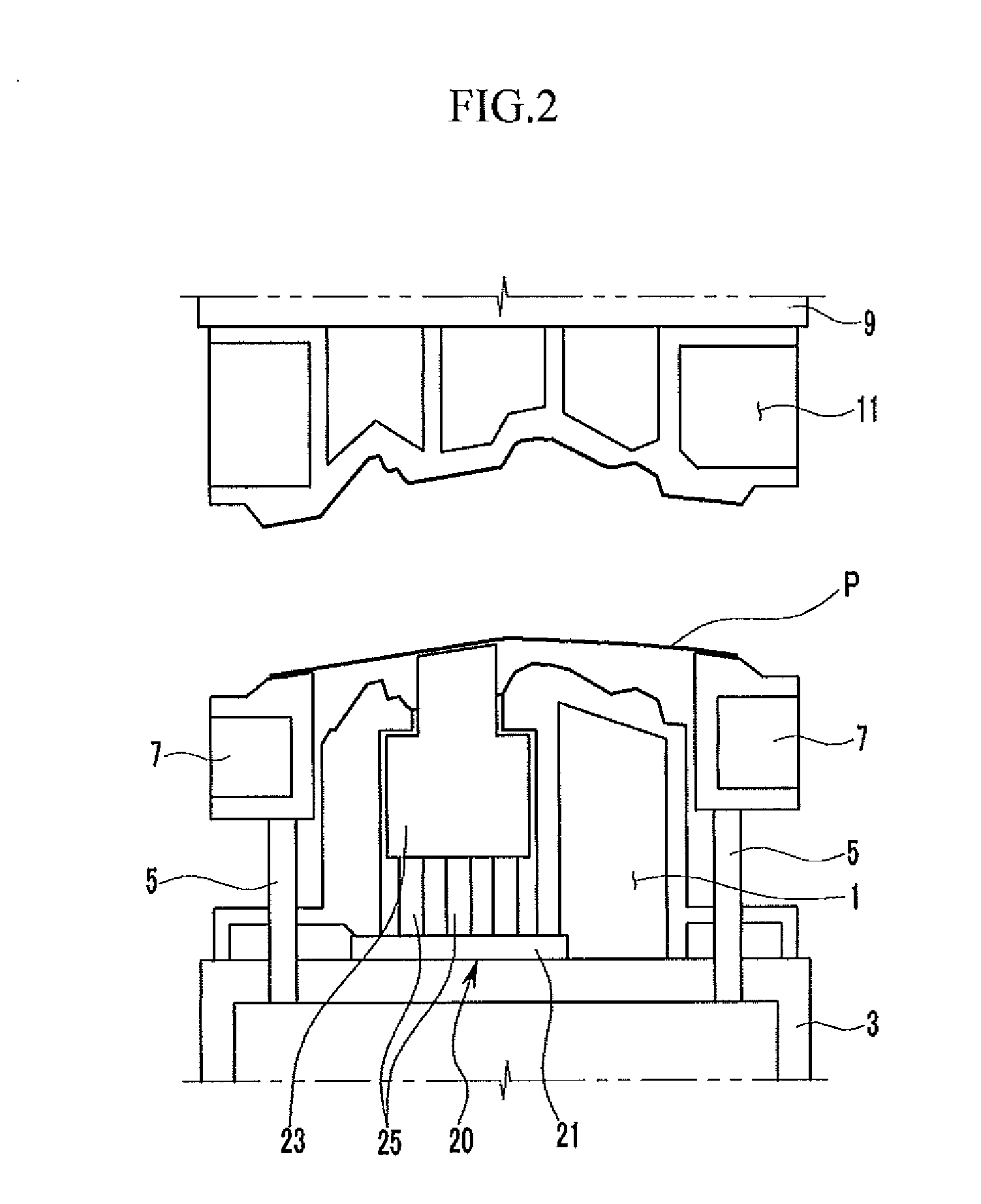

[0035]An exemplary embodiment of the present invention will hereinafter be described in detail with reference to the accompanying drawings.

[0036]Exemplary embodiments described in the present specification and a configuration shown in the drawings are just an exemplary embodiment of the present invention, but are not limited to the spirit and scope of the present invention. Therefore, it should be understood that there may be various equivalents and modifications capable of replacing them at the time of filing of the present application.

[0037]Also, it is understood that the term “vehicle” or “vehicular” or other similar term as used herein is inclusive of motor vehicles in general such as passenger automobiles including sports utility vehicles (SUV), buses, trucks, various commercial vehicles, watercraft including a variety of boats and ships, aircraft, and the like, and includes hybrid vehicles, electric vehicles, plug-in hybrid electric vehicles, hydrogen-powered vehicles and othe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface shape | aaaaa | aaaaa |

| shape | aaaaa | aaaaa |

| molding depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com